Catalytic conversion process of heavy petroleum hydrocarbon for increasing output of ethylene and propylene

A catalytic conversion method and heavy oil technology, applied in the field of catalytic conversion, can solve the problems of reducing the initial contact temperature between raw material oil and regenerated catalyst, affecting the atomization effect of raw material, and adverse effects on catalyst activity, so as to achieve a wide range of raw materials and increase production. rate, the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] This example is the implementation effect of the method provided by the present invention.

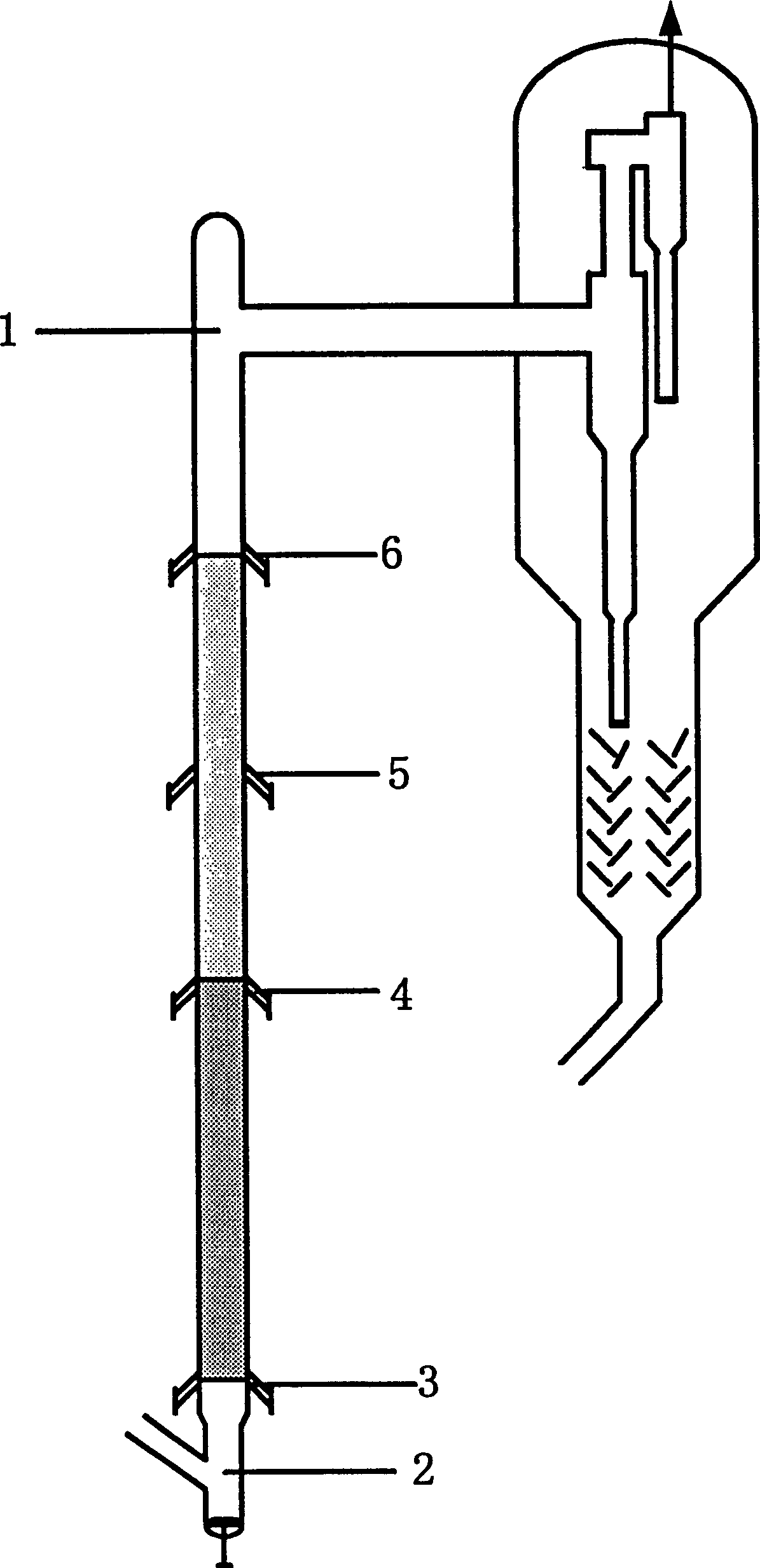

[0031] Using Feedstock A and CEP-1 catalyst, a catalytic conversion experiment was carried out on a medium-sized riser unit with continuous reaction-regeneration operation. The riser reactor has a diameter of 16 mm and a total height of 10 meters. It is equipped with five layers of nozzles. The bottom is the steam nozzle of the pre-lift section. The distance from the bottom feed nozzle to the bottom is 1 meter, and the distance from the top feed nozzle to the bottom is 3.5 meters. The steam injection nozzle in the middle of the reactor is 6.5 meters away from the bottom and the steam injection nozzle in the upper part of the reactor is 8 meters away from the bottom. The steam injection amount of the steam nozzle in the pre-lifting section, the lower feed nozzle, the upper feed nozzle, the steam injection nozzle in the middle of the reactor and the steam injection nozzle in the u...

example 2

[0034] This example illustrates the situation that ethylene and propylene are prepared by catalytic conversion of heavy petroleum hydrocarbons as raw materials using the method provided by the invention.

[0035] Catalytic conversion tests were carried out on the same medium-sized riser unit as in Example 1 using Feedstock A and CEP-1 catalyst. Steam injection mode is the same as Example 1.

[0036] The test adopts the single-pass operation method. After the raw material oil is heated to about 350°C by the preheating furnace, 60% by weight of the raw material oil enters the riser reactor through the lower feeding nozzle, and 40% by weight of the raw material oil passes through the upper feeding nozzle. The feed nozzle enters the riser reactor, and the feed oil contacts the catalyst to carry out the catalytic conversion reaction. The reaction product, water vapor and unused catalyst enter the settler from the outlet of the reactor, and the reaction product and catalyst are qui...

example 3

[0042] This example illustrates the situation that ethylene and propylene are prepared by catalytic conversion of heavy petroleum hydrocarbons as raw materials using the method provided by the invention.

[0043] Catalytic conversion tests were carried out on the same medium-sized riser unit as in Example 1 using Feedstock B and CRP-1 catalyst. The steam injection amount of the steam nozzle in the pre-lifting section, the lower feed nozzle, the upper feed nozzle, the steam injection nozzle in the middle of the reactor and the steam injection nozzle in the upper part of the reactor account for 10% by weight and 20% by weight of the total steam injected into the riser, respectively , 10% by weight, 10% by weight and 50% by weight.

[0044] The test adopts the operation mode of full recovery. The raw oil is heated to about 350°C by the preheating furnace and then enters the riser reactor through the lower feed nozzle, and all the re-refined oil slurry enters the riser reactor thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com