Method for preparing epoxy crosslinking agent

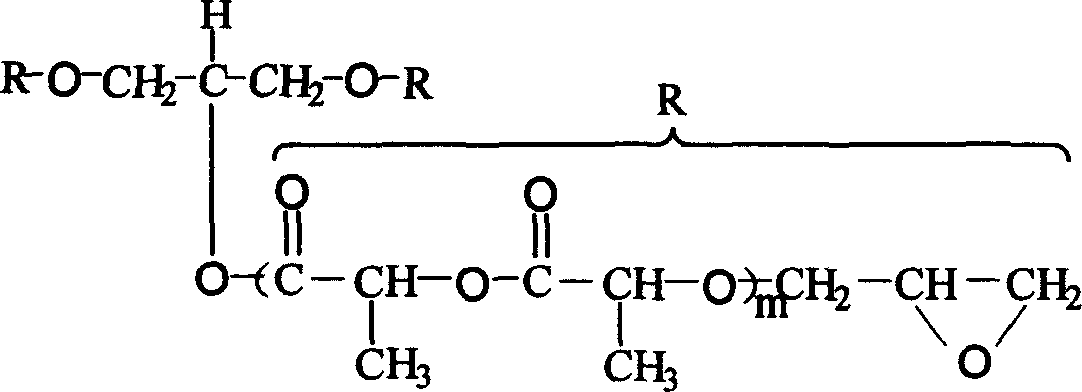

A technology of cross-linking agent and epoxy group, which is applied in the field of preparation of epoxy-based cross-linking agent, can solve the problems of cell toxicity, matching degradation rate, and poor cell affinity, so as to broaden the range of selection, Wide application and enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 13.5g of lactide, 6g of PEG400 and 0.17g of stannous octoate were mixed and stirred, blown with nitrogen, heated to 130°C, and reacted for 6 hours. The crude product was dissolved in chloroform, filtered and dissolved in n-hexane, separated into layers, filtered again, and repeated several times until the liquid was completely transparent, and then dried under vacuum at 55°C for one day. Take 5g of the product, 7.5g of epichlorohydrin and 0.15g of benzyltriethylammonium chloride, add 4g of 50% sodium hydroxide dropwise for 30min under stirring at room temperature, then stir and react at 60°C for 1h; cool, filter with suction, and separate the liquids The organic layer was separated, washed three times with 60 ml of saturated brine, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to obtain a light yellow transparent liquid.

Embodiment 2

[0025] 15g of lactide, 2g of glycerin and 0.15g of stannous octoate were mixed and stirred, nitrogen was blown, the temperature was raised to 130°C, and the reaction was carried out for 6 hours. The crude product was dissolved in chloroform, filtered and dissolved in n-hexane, separated into layers, filtered again, and repeated several times until the liquid was completely transparent, and then dried under vacuum at 55°C for one day. Take 5g of the product, 5g of epichlorohydrin and 0.3g of benzyltriethylammonium chloride, add 3g of 50% sodium hydroxide dropwise for 30min under stirring at room temperature, then stir and react at 60°C for 1h; The organic layer was taken out, washed three times with 60 ml of saturated brine, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to obtain a light yellow transparent liquid.

Embodiment 3

[0027] Mix and stir 12g of lactide, 6g of PEG800 and 0.15g of stannous octoate, blow nitrogen, raise the temperature to 130°C, and react for 6 hours. The crude product was dissolved in chloroform, filtered and dissolved in n-hexane, separated into layers, filtered again, and repeated several times until the liquid was completely transparent, and then dried under vacuum at 55°C for one day. Take 5g of the product, 5g of epichlorohydrin and 0.15g of benzyltriethylammonium chloride, add 4g of 50% sodium hydroxide dropwise for 30min under stirring at room temperature, then stir and react at 60°C for 1h; The organic layer was taken out, washed three times with 60 ml of saturated brine, dried over anhydrous magnesium sulfate, and distilled under reduced pressure to obtain a light yellow transparent liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com