First-stage selective hydrogenation catalyst for pyrolysis gasoline

A technology for pyrolysis gasoline and catalysts, applied in refining to remove heteroatoms, etc., can solve the problem of low selectivity of diene hydrogenation, achieve the effect of improving selectivity, improving the utilization rate of palladium, and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

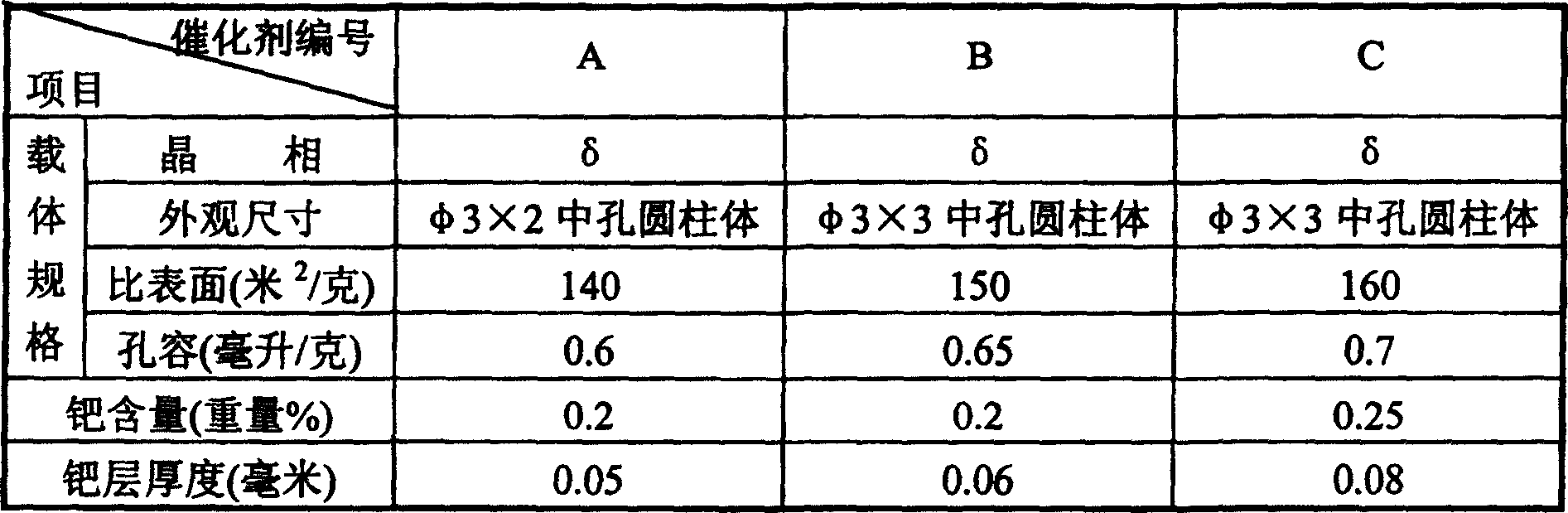

[0012] Pre-soak the carrier with deionized water, then filter to dry the water, impregnate the carrier with palladium chloride solution, then wash, dry, and roast in the air to obtain the catalyst A, B or C of the present invention respectively, and its physical properties are as shown in the table 1.

[0013] Table 1

[0014]

Embodiment 4

[0016] Carry out activity evaluation in 30 milliliters of isothermal trickle bed reactors with A, B, C catalyst described in embodiment 1~3 respectively, evaluation condition is: catalyst loading is 30 milliliters (bed height is 23.5~ 25 cm), the reaction pressure is 2.7-2.8MPa, the bath temperature is 52-56°C, and the raw material is C 5 ~C 9 Distillate, liquid space velocity 8.0 hours -1 , the hydrogen / oil ratio (volume / volume) is 60:1, and the inlet temperature is 44-45°C. The evaluation results are shown in Table 2.

[0017]

[0018] *g iodine / 100g oil

Embodiment 5

[0020] Carry out 1000 hour evaluations in 100 milliliters of adiabatic trickle-bed reactors with the B catalyst of embodiment 2, evaluation condition is: catalyst loading is 100 milliliters (bed height is 30 centimetres), reaction pressure is 2.7~2.8MPa, bath Temperature is 52~56℃, raw material is C 5 ~C 9 Distillate, fresh oil space velocity 3.0 hours -1 (volume), circulating oil space velocity is 8.8 hours -1 (volume), raw material is fresh oil plus circulating oil, hydrogen / fresh oil (volume / volume) = 110:1, inlet temperature is 44-45°C, see evaluation results table 3.

[0021] Cumulative reverse

[0022] *g iodine / 100g oil

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com