Method for mfg diode

A manufacturing method and diode technology, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high cost, expensive substrate, and slow diode speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Refer to Table 2 to make a diode under the process conditions.

[0093] The specifications of the epitaxial wafers used are as follows:

[0094] Silicon substrate resistivity 3μΩCM impurity As

[0095] Epitaxial layer resistivity 0.8ΩCM thickness 8μm

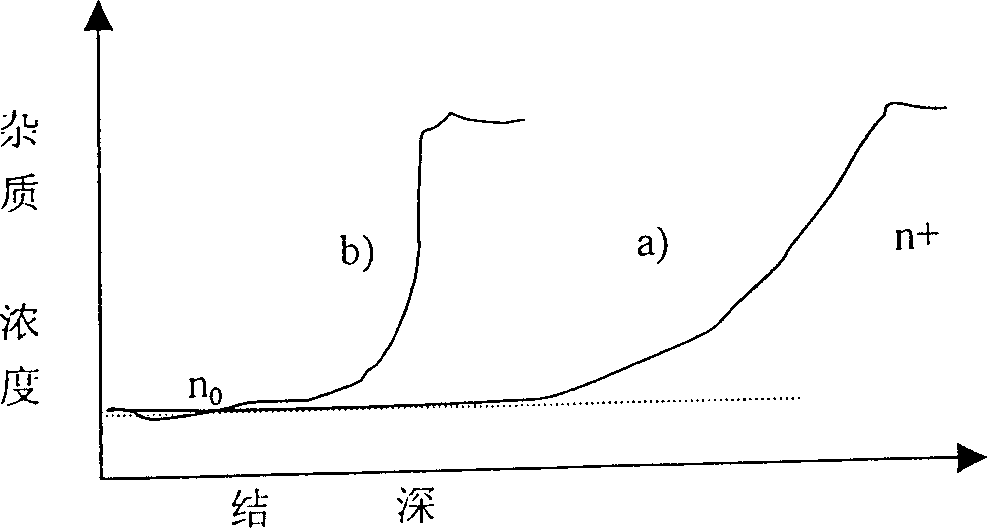

[0096] After making a diode, measure the epitaxial layer thickness and concentration distribution results, see image 3 , b). At this time, the thickness of the epitaxial layer reduced by the steep distribution effect of the impurity layer of the silicon epitaxial layer is 1 μm, that is, the actual thickness of the epitaxial layer is 7 μm. As a result of making a diode, the forward voltage drop of the diode, V f is 0.65V. This is because of the thickness of the actual epitaxial layer.

[0097] The specific process steps are as follows:

[0098] 1. Clean the semiconductor silicon wafer. Ammonium hydroxide (NH 4 OH), hydrogen peroxide (H 2 o 2 ) and water (H 2 O) cleaning the silicon wafer at 65° C. for 2.5 minut...

Embodiment 2

[0147] On the basis of Example 1, a diode is made under the process conditions in Table 2.

[0148] The specifications of the epitaxial wafers used are as follows.

[0149] Silicon substrate resistivity 3μΩCM impurity As

[0150] Epitaxial layer resistivity 0.5ΩCM thickness 5μm

[0151] As a result of making a diode, the forward voltage drop of the diode, V f It is 0.47V, which has been improved.

[0152] Concrete process step is with embodiment one.

Embodiment 3

[0154] It is the same as Example 2, but in Table 2, when polysilicon is used as the film, the heat treatment temperature is 1000°C, oxidized for 2 hours, and the others are completely the same.

[0155] The characteristic of the made diode is basically the same as that of the second example.

[0156] Concrete process steps are with embodiment two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com