Single particle nano-garlicin micro-capsule, and its preparation method

A technology of single particle and allicin, which is applied in the direction of microcapsules, capsule delivery, pharmaceutical formulations, etc., can solve the problems of high processing cost, no process and dosage form, and no nano-scale allicin products, so as to reduce blood lipids, Activate phagocytosis and enhance human immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

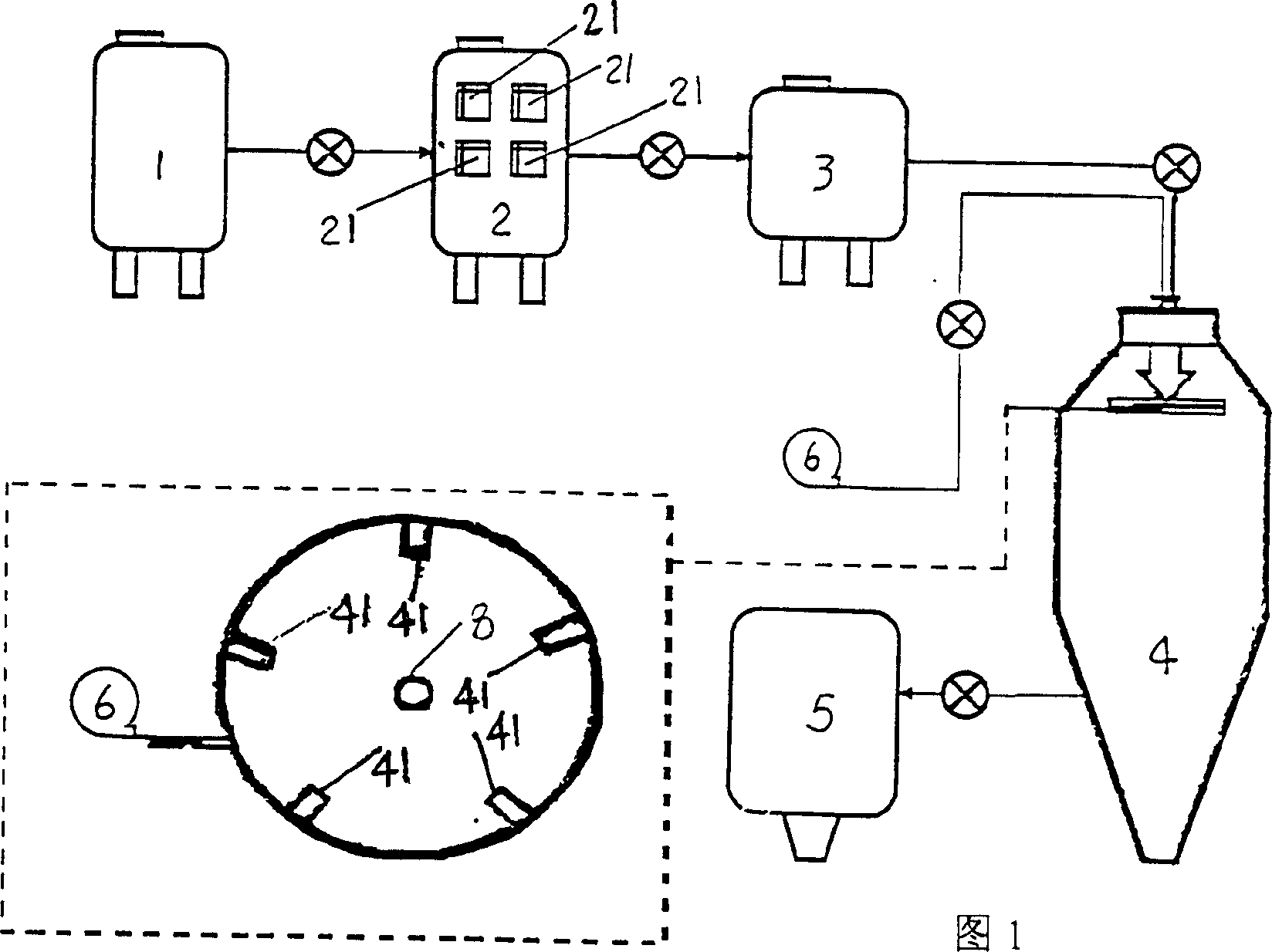

[0035] Fig. 1 is the technological process schematic diagram of preparing single-particle nano-allicin microcapsules of the present invention; Accompanying drawing 2 is the schematic diagram of the positional relationship between the high-pressure spray nozzle in the feed pipe 8 and the annular nano-jet atomizer 4;

[0036] The steps for preparing single-particle nano-allicin microcapsules in this embodiment are:

[0037] 1) Select 400 kg of fresh garlic as a raw material and put it into the washing container 1, and wash and purify it with distilled water;

[0038] 2) Put the washed and purified garlic raw material in a container, then add 90% ethanol (of course, 70% ethanol is also acceptable) solvent to immerse the garlic raw material, put it into the multidimensional microwave environment 2 for multidimensional Microwave-induced extraction, the extraction temperature is 50°C, the extraction pressure is 0.12Mpa, the active ingredients in the garlic raw material are extracted...

Embodiment 2

[0045] The steps of preparing single particle nano allicin microcapsules of present embodiment 2 are:

[0046] 1) Select 700 kg of fresh garlic as a raw material and put it into the scrubber 1, and wash and purify it with distilled water;

[0047] 2) Put the washed and purified garlic raw material in a container, then add dichloromethane with a concentration of 100%, the amount of which is limited to immerse the garlic raw material, put it into a multi-dimensional microwave environment 2 for multi-dimensional microwave-induced extraction, The extraction temperature is 40°C, the extraction pressure is 0.06Mpa, and the active ingredients in the garlic raw material are extracted into the solvent, and the active ingredients include allicin, allicin, ajoene, selenium and germanium;

[0048] 3) The extract solution is filtered and sent to the concentration tank 3, and concentrated under reduced pressure at 50° C. to obtain a mixed extract concentrate containing garlic active ingredi...

Embodiment 3

[0054] The steps of present embodiment 3 preparation single-particle nano allicin microcapsules are:

[0055] 1) Select 700 kg of fresh garlic as a raw material and put it into the scrubber 1, and wash and purify it with distilled water;

[0056] 2) Put the washed and purified garlic raw material in a container, then add distilled water until the amount of water has submerged the raw material, put it into a multi-dimensional microwave environment 2 for multi-dimensional microwave-induced extraction, the extraction temperature is 45°C, and the extraction pressure is 0.10 Mpa, the active ingredients in the garlic raw material are extracted into the solvent, and the active ingredients include allicin, allicin, ajoene, selenium and germanium;

[0057] 3) The extract solution is filtered and sent to the concentration tank 3, and concentrated under reduced pressure at 30° C. to obtain a mixed extract concentrate containing garlic active ingredients, and the mixed extract concentrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com