Method of depositing high density loading metal platinum on carbon nanometer pipe surface using oriented chemistry

A carbon nanotube and metal-loaded technology, which is applied in chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., can solve the problems of low loading rate, limited prospects, and high cost, and achieve uniform distribution, excellent performance, and high platinum The effect of load ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

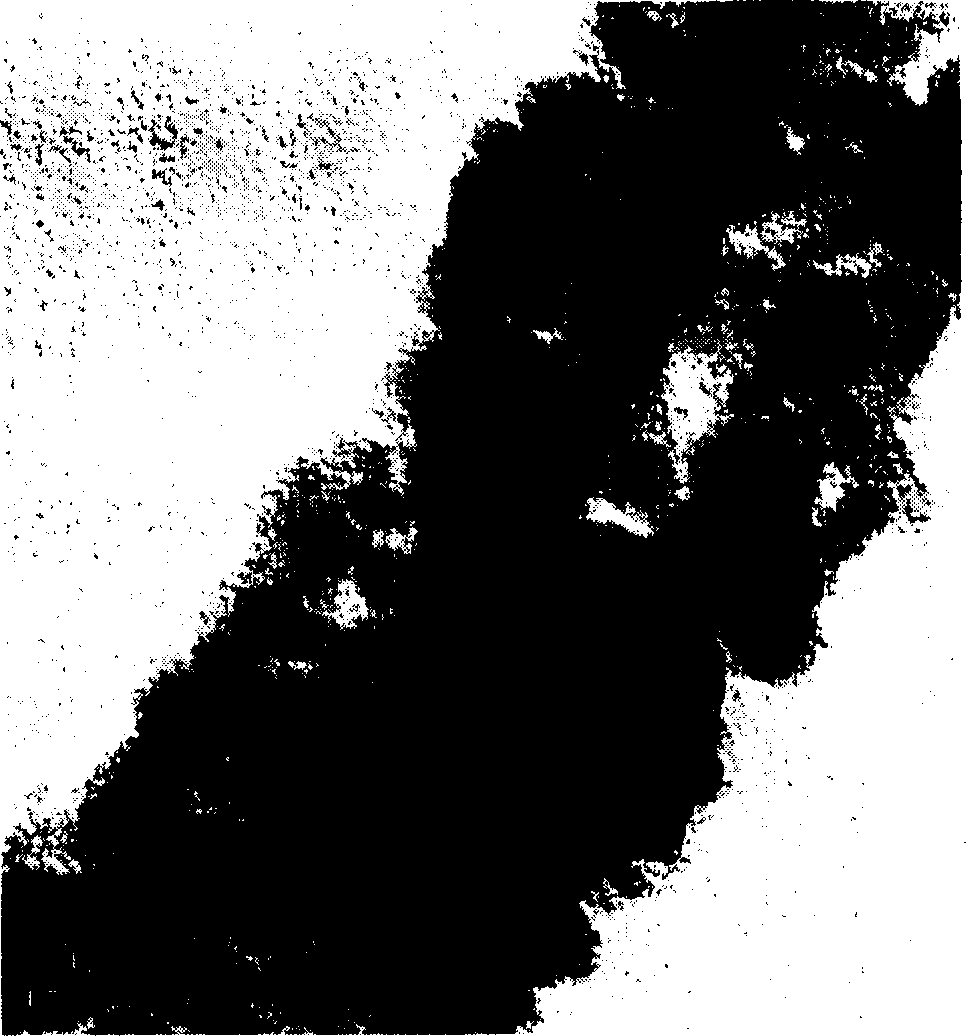

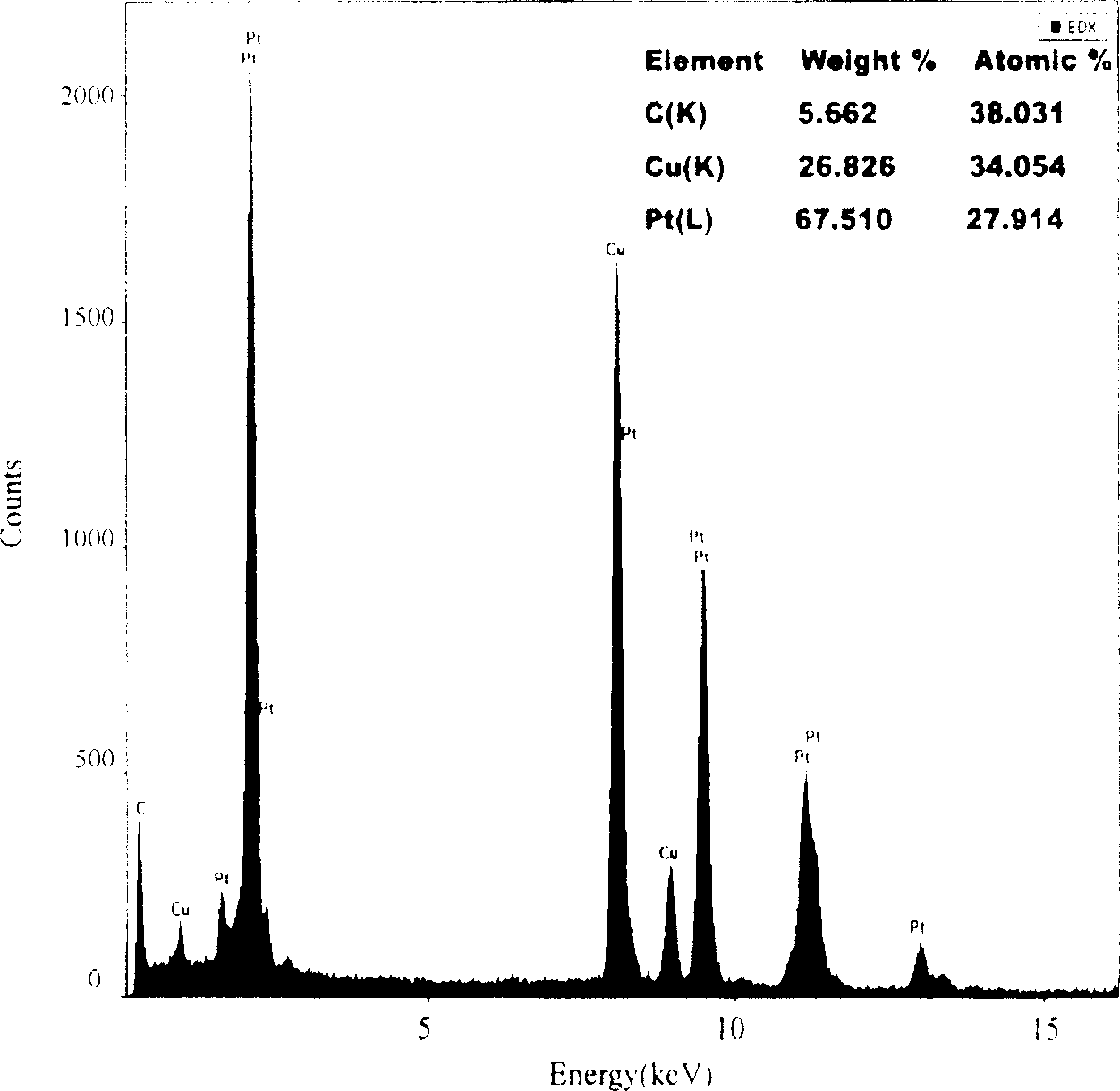

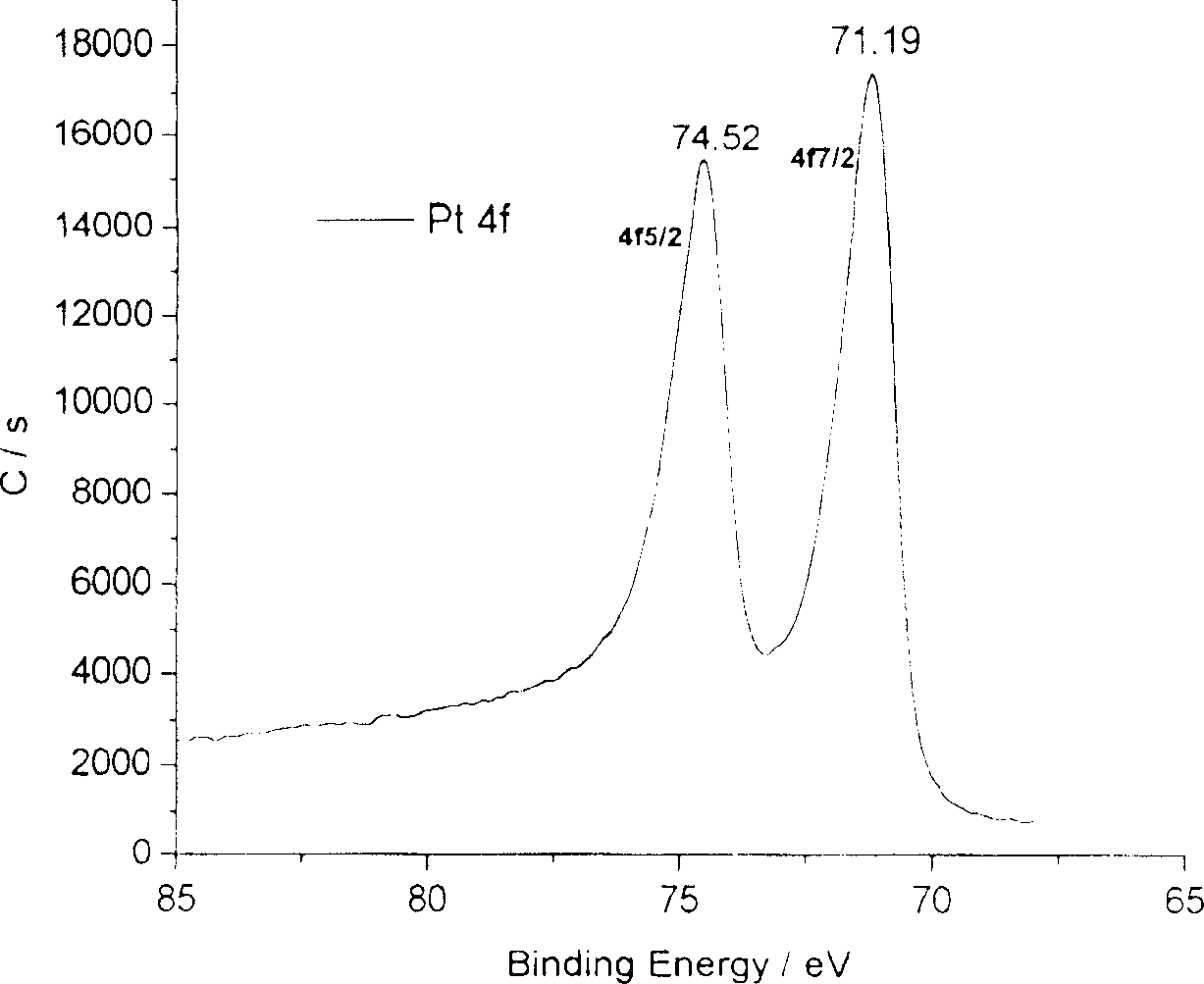

[0014] Embodiment 1: 1) surface oxidation treatment of nanotubes: 1 gram of purified single-walled carbon nanotubes (provided by the Metal Institute of the Chinese Academy of Sciences) or multi-walled carbon nanotubes (provided by the Department of Chemistry, Xiamen University) was added to a round bottom flask, and then Add 200 ml of 2.6M nitric acid, heat to boil, reflux for about 4 hours, then filter, wash with water until neutral, and dry at 150°C for 2 hours to obtain a surface oxidized carbon nanotube sample for future use.

[0015] 2) Nanotube-supported platinum nanoparticles: add 0.1 g of carbon nanotubes after surface oxidation treatment, 0.1 g of dodecyltrimethylammonium bromide, 0.1 g of chloroplatinic acid and 1000 ml of ethylene glycol in a round bottom flask , After ultrasonic dispersion, the round bottom flask was placed in an oil bath, heated and stirred, and the reaction was stopped after 2 hours of reaction.

[0016] 3) The product was centrifuged, washed wit...

Embodiment 2~8

[0020] The method for loading platinum nanoparticles on nanotubes is the same as in Example 1, and the remaining conditions and results are shown in Table 1:

[0021] Reality

Shi

example

carbon nanotubes

A

Surfactant

B

platinum salt

C

warm

Spend

(℃)

reaction

time

h

Time)

Ethylene glycol

Platinum loading

Rate

(%)

grain level

Inch

(nm)

kind

kind

content

(gram)

kind

kind

contain

quantity

(gram)

kind

kind

contain

quantity

(gram)

1

A1

0.1

B1

0.1

C1

0.1

170

2

1000mL

50

5

2

A1

10

B2

5

C2

2.5

130

1.5

1000mL

20

3

3

A1

9

B5

10

C1

1

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com