Preparation method of polyaniline/graphene controllable load platinum nanoparticles

A technology of graphene and polyaniline, which is applied in the field of synthesis of PANI/rGNS nanocomposite materials, can solve problems such as easy agglomeration of products, poor dispersion, and influence on the uniform dispersion of PtNPs, and achieve the effects of preventing agglomeration, high-efficiency loading, and excellent electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of rGNS: First, graphene oxide was prepared by the improved Hummers method (Li, D.; Muller, M. B.; Gilje, S.; Kaner, R. B.; Wallace, G. G. Nat. Nanotechnol. 2008, 3, 101-105 ; Hummers, W. S.; Offeman, R. E. J Am Chem Soc. 1958, 80, 1339; Cote, L. J.; Kim, F.; Huang, J. X. J Am Chem Soc. 2009, 131, 1043-1049.); Add 1 mg / mL graphene oxide into a 250 mL three-neck flask, add 150 mg NaBH 4 , mechanically stirred in a water bath at 80°C for 6 hours, then centrifuged and washed the product with twice distilled water until the supernatant was neutral, the centrifugal cleaning speed was 12000 r / min~14000 r / min, and the centrifugation time was 5 minutes. The obtained product was dispersed into 10 mL of double-distilled water, and ultrasonicated for 20 minutes (ultrasonic power was 150 W~200 W), and uniformly dispersed reduced graphene was obtained;

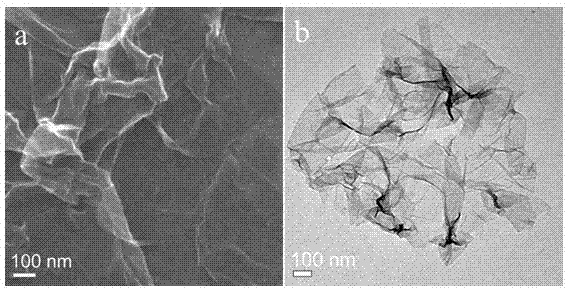

[0026] (2) Synthesis of PANI / rGNS nanocomposites by liquid / liquid interface method: 5 mg aniline was dissolved in...

Embodiment 2

[0030] (1) For the preparation method of rGNS and PANI / rGNS, refer to steps (1) and (2) of Example 1.

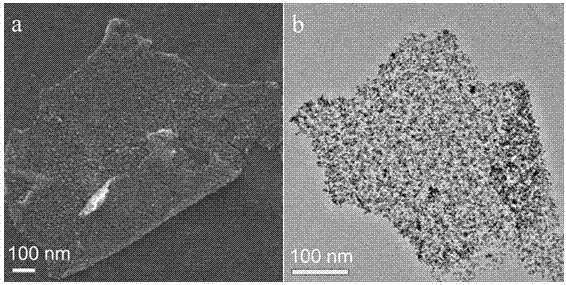

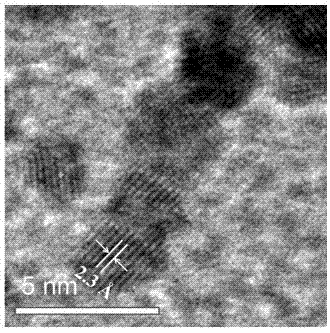

[0031] (2) Preparation of Pt / PANI / rGNS catalysts with different Pt loadings: disperse 0.5 mg, 1.0 mg, 2.0 mg, and 5.0 mg of PANI / rGNS in 4 mL of twice-distilled water, sonicate for 20 min, and then add 5 mg h 2 PtCl 6 solution and 0.25 mL HCOOH solution, and stirred magnetically at about 25°C for 24 hours, then centrifuged the product with double distilled water (centrifugal cleaning speed was 10000 r / min~12000 r / min), and the centrifugation time was 3 minutes. The product was vacuum-dried at 40 °C for 48 hours, and the mass fractions of Pt NPs of Pt / PANI / rGNS nanocatalysts were 86 wt %, 75 wt %, 57 wt % and 39 wt %, respectively.

[0032] The transmission electron microscopy results of the prepared Pt / PANI / rGNS nanocatalysts are shown in Figure 7 , it can be seen from the figure that the particle size of Pt NPs does not change significantly with the change of loading de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com