Dandelion-shaped gold nanoparticles@polyaniline nanocomposite prepared by one-pot method and its preparation method and application

A technology of nanocomposite materials and gold nanoparticles, applied in the direction of material electrochemical variables, etc., can solve the problems of inability to meet large-scale industrial production, complicated operation, cumbersome operation, etc., and achieve suitable for large-scale production, simple operation, and uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing dandelion-shaped gold nanoparticles@polyaniline nanocomposites in one pot, specifically including the following steps:

[0032] Under normal temperature conditions, 0.18mL of aniline monomer was uniformly dispersed in 18mL of 0.5mol / L hydrochloric acid solution, and under continuous stirring, 1.8mL of 6mmol / L chloroauric acid solution was added dropwise, and after 12 hours of reaction, a blue The product, the product was centrifuged at 8000 rpm for 15 minutes, washed with absolute ethanol, deionized water, and N-methylpyrrolidone in turn until the filtrate was colorless, and dried in vacuum at 60°C for 12 hours to obtain dandelion-shaped gold nanoparticles@poly Aniline nanocomposites.

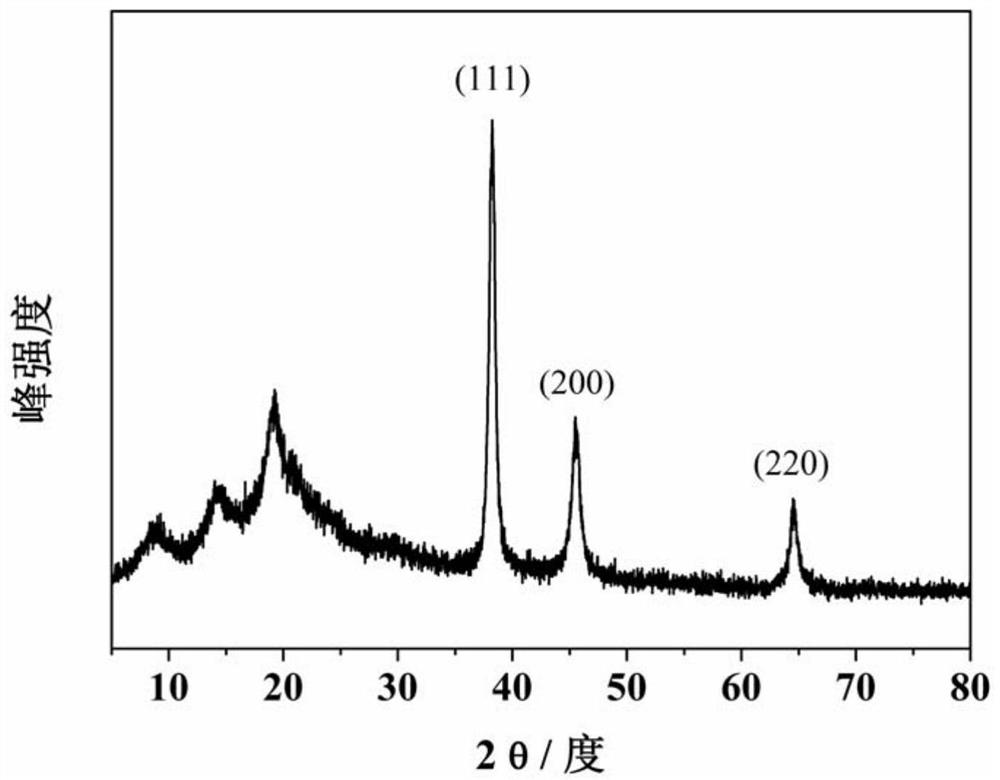

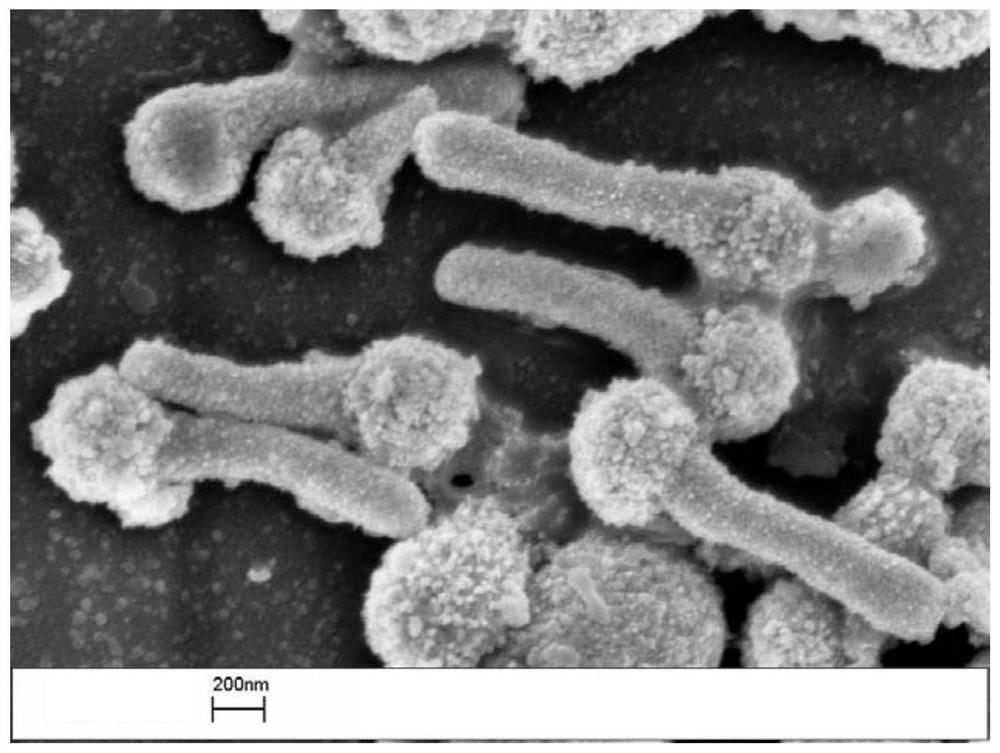

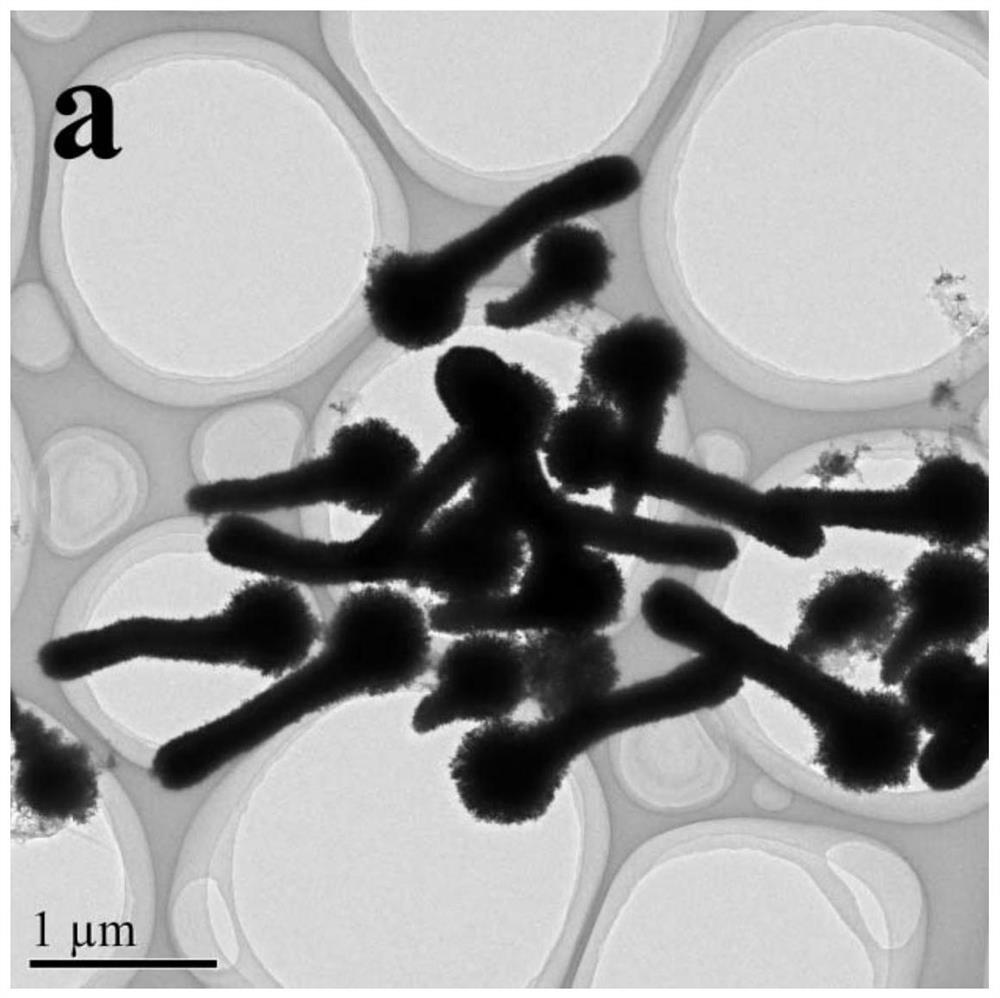

[0033] Structural performance test: XRD (solid powder X-ray diffraction analysis) technology was used to characterize gold nanoparticles @ polyaniline nanocomposites (see figure 1 ), there is a broad peak between 2θ position 10-30° in the material, which is the ch...

Embodiment 2

[0037] A method for preparing dandelion-shaped gold nanoparticles@polyaniline nanocomposites by one-pot method, which specifically includes the following steps:

[0038] Under normal temperature conditions, 0.18mL of aniline monomer was uniformly dispersed in 9mL of 1.0 mol / L hydrochloric acid solution, and under continuous stirring conditions, 3.6mL of 12mmol / L chloroauric acid solution was added dropwise, and after 6 hours of reaction, a blue The product, the product is centrifuged at 10,000 rpm for 10 minutes, washed with absolute ethanol, water, and N-methylpyrrolidone in turn until the filtrate is colorless, and then vacuum-dried at 80°C for 8 hours to obtain dandelion-shaped gold nanoparticles@polyaniline nano composite material.

[0039] Structural performance test: XRD (solid powder X-ray diffraction analysis) technology is used to characterize the gold nanoparticles@polyaniline nanocomposite material obtained in this example, and the XRD results are consistent with fig...

Embodiment 3

[0044] A method for preparing dandelion-shaped gold nanoparticles@polyaniline nanocomposites by one-pot method, which specifically includes the following steps:

[0045] Under normal temperature conditions, 0.18mL of aniline monomer was uniformly dispersed in 12mL of 0.75 mol / L hydrochloric acid solution, and under continuous stirring conditions, 2.7mL of 9mmol / L chloroauric acid solution was added dropwise, and after 9 hours of reaction, a blue The product, the product was centrifuged at 9000 rpm for 12.5 minutes, washed with absolute ethanol, water, and N-methylpyrrolidone in sequence until the filtrate was colorless, and then vacuum-dried at 70°C for 10 hours to obtain dandelion-shaped gold nanoparticles@polyaniline nanocomposites.

[0046] Structural performance test: XRD (solid powder X-ray diffraction analysis) technology is used to characterize the gold nanoparticles@polyaniline nanocomposite material obtained in this example, and the XRD results are consistent with fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com