Preparation method of polyaniline/precious metal nanometer composite material modified electrode

A technology of nanocomposite materials and modified electrodes, which is applied in the field of preparation of polyaniline/noble metal nanocomposite modified electrodes, which can solve the problems of difficult combination of particle size and activity, complex synthesis process, and high preparation cost, so as to improve catalytic performance , The method is simple, and the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

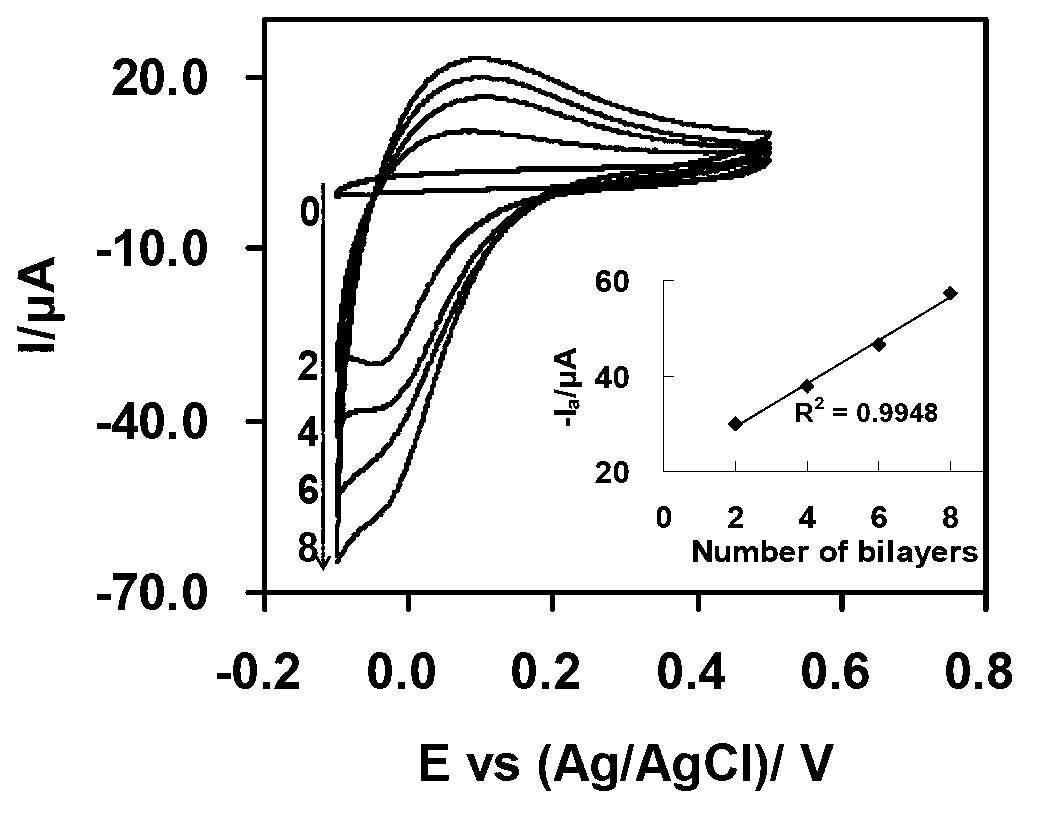

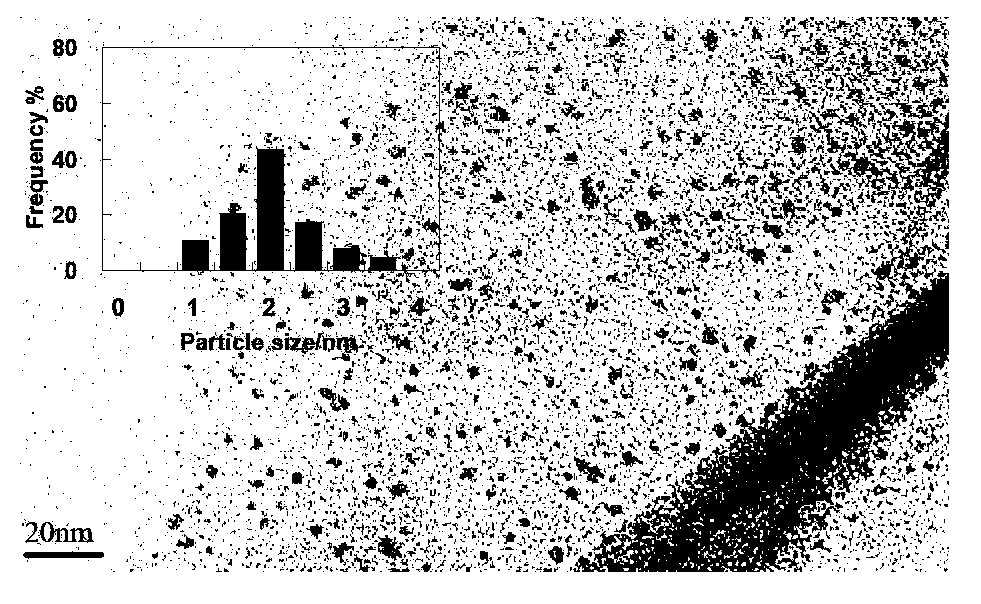

[0040] Preparation of polyaniline / Pd nanocomposite modified glassy carbon electrodes: 1.0 μm, 0.3 μm, 0.05 μm α-Al 2 o 3 Powder polishing, rinse with pure water and sonicate for 5 minutes after each polishing, and finally the glassy carbon sheet is ultrasonicated in ethanol and pure water for 5 minutes, rinse, and dry with high-purity nitrogen. Put the cleaned glassy carbon electrode in a 3×10 -3 mol / L containing p-aminobenzenesulfonic acid in 0.1mol / L lithium perchlorate ethanol solution, platinum wire as counter electrode, with Ag / Ag + (absolute ethanol solution) as the reference electrode, in the potential range of 0.5 ~ 1.5V, 10 cycles of cyclic potential scanning at a scan rate of 50mV / s, take out water and rinse to obtain a glassy carbon electrode functionally modified with sulfonic acid groups ; Then put the electrode in a water-soluble conductive polyaniline solution for adsorption for 30 minutes; take it out and rinse it with an aqueous HCl solution with a pH of 3.0...

Embodiment 2

[0043] Preparation of polyaniline / Pd nanocomposite modified gold electrode:

[0044] Put the cleaned gold electrode in a container containing 2×10 -3 mol / L thioglycolic acid solution for 12 hours, and then take it out and wash it with ethanol and water respectively to obtain a gold electrode modified by carboxyl group; then put the electrode in a water-soluble conductive polyaniline solution for adsorption for 20 minutes; take it out with pH3.0 Rinse with aqueous HCl solution and then put in the solution containing 1×10 -3 mol / L K 2 PdCl 6 0.5mol / L of H 2 SO 4 Adsorbed in the solution for 30 minutes, and repeated the last two steps to obtain (PANI / PdCl 6 2- ) multilayer film electrodes.

[0045] The multilayer film electrode was placed in a 0.1mol / L KCl solution that was passed through nitrogen to remove oxygen, and electrolyzed at -0.7V for 10 minutes, washed with water, and dried with nitrogen to obtain a gold electrode deposited with polyaniline / palladium nanocomposi...

Embodiment 3

[0047] Preparation of polyaniline / Pd nanocomposite modified ITO electrode:

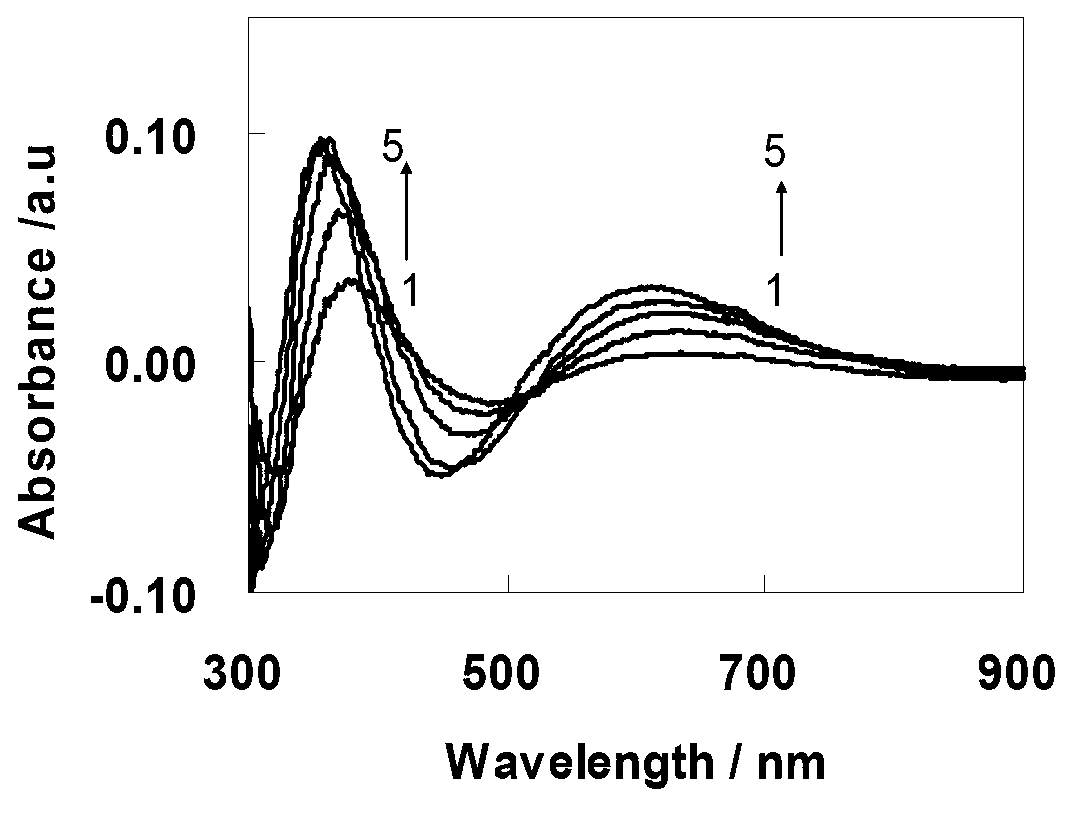

[0048] Soak the ITO electrode in ethanol + saturated NaOH solution and wash it with pure water to obtain a clean ITO electrode, put the clean ITO electrode in the water-soluble conductive polyaniline solution for 20 minutes; take it out and rinse it with pH 3.0 HCl aqueous solution Put in the containing 2×10 -3 mol / L K 2 PdCl 6 H 2 SO 4 Adsorbed in the solution for 30 minutes, and repeated the last two steps to obtain (PANI / PdCl 6 2- ) Multilayer film modified ITO electrode. image 3 for (PANI / PdCl 6 2- ) UV-vis spectrum curves of multilayer films growing different layers on ITO electrodes.

[0049] The multi-layer film modified ITO electrode was placed in a 0.1mol / L KCl solution protected by nitrogen gas and electrolyzed at -0.7V for 10min, washed with water, and dried with nitrogen gas to obtain an ITO electrode deposited with polyaniline / palladium nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com