Monodispersity nano/micron polymer microsphere resin and method for preparing same

A polymer and monodisperse technology, applied in the field of preparation of nano/micro polymer microspheres, can solve the problems of limiting the application and effectiveness of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

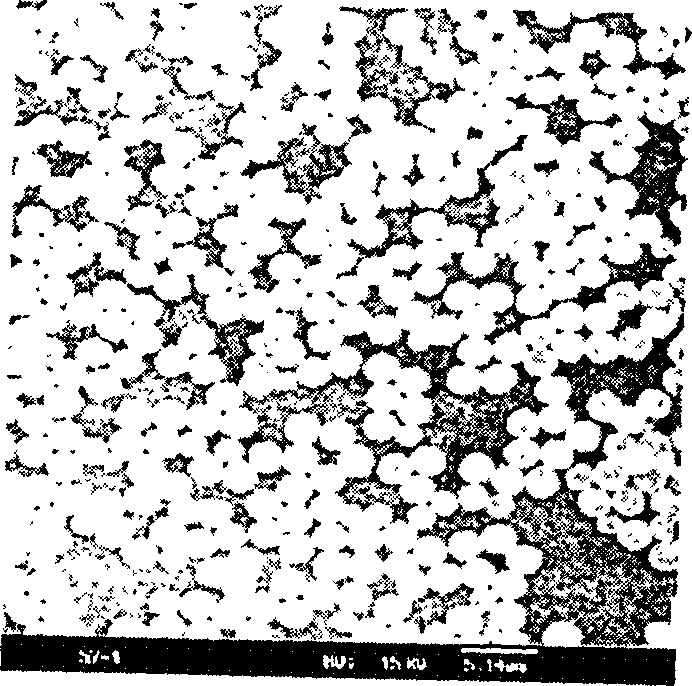

[0030] Example 1: In a 500 ml two-necked flask with a fractionating column and a condenser, add divinylbenzene (10 ml, 9.2 g, 70.7 mmol), N, N'-azobisisobutyronitrile (AIBN) (0.184 g, 1.12 mmol, 2 wt % relative to the mass of the monomer) and 400 ml of acetonitrile. Heating the reaction system, making the reaction system rise from room temperature to boiling state in about 30 minutes, and reacting in the boiling state for 30 minutes. After half of the solvent in the reaction system was distilled off within 1.5 hours, the reaction ended. When the reaction system kept boiling for 15 minutes, it changed from a uniform and transparent state to a turbid milky white. Polymer microspheres were gradually formed during solvent evaporation and precipitated from the reaction system. After the reaction, the polymer microspheres were separated by filtration under reduced pressure, and then the polymer microspheres were washed three times with tetrahydrofuran (THF), acetone, and ether in ...

example 2

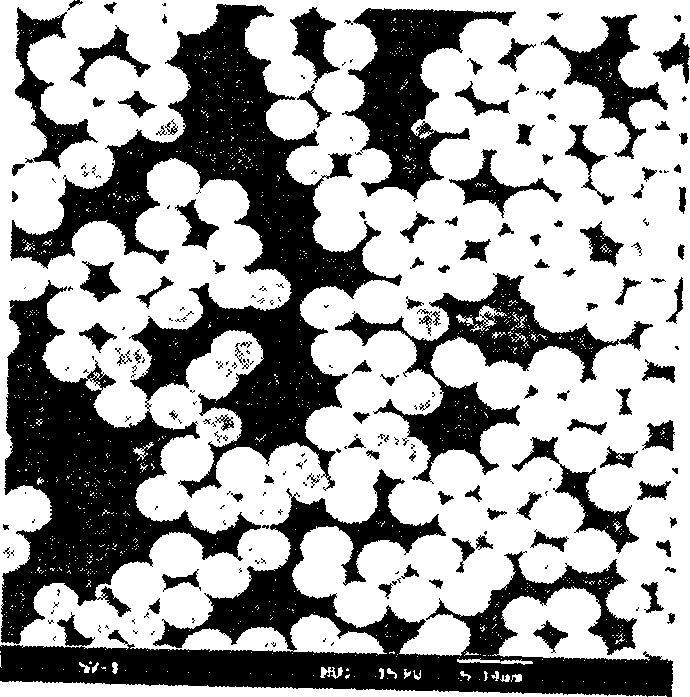

[0032] Example 2: In the system after the reaction of Example 1 was stopped, continue to add AIBN (0.184 grams, 1.12 mmol) initiator and 200 milliliters of acetonitrile. Heating the reaction system, making the reaction system rise from room temperature to boiling state in about 30 minutes, and reacting in the boiling state for 30 minutes. After half of the solvent in the reaction system was distilled off within 1.5 hours, the reaction ended. The polymer microspheres gradually grow further during the solvent evaporation process without secondary nucleation to form smaller polymer microspheres, and the polymer microspheres still maintain good monodispersity. Precipitated from the reaction system. After the reaction, the polymer microspheres were separated by filtration under reduced pressure, and then the polymer microspheres were washed three times with THF, acetone, and ether in sequence. The resulting polymer microspheres were dried in a vacuum oven to constant weight. The...

example 3

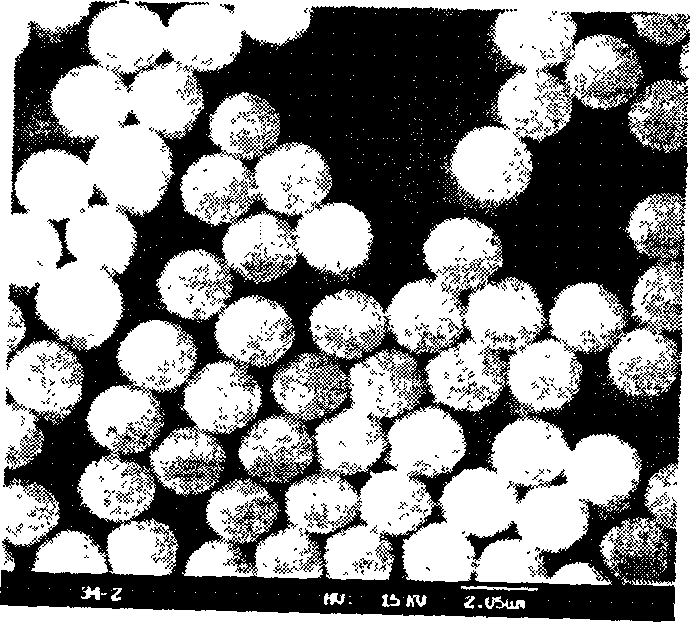

[0033]Example 3: In a 100 milliliter two-necked flask with a fractionating column and a condenser, add divinylbenzene (1.2 milliliters, 1.1 grams, 8.5 mmol), p-chloromethylene styrene (CMSt, 0.8 milliliters, 5.2 mmol), AIBN (0.04 g, 0.24 mmol, 2 wt % relative to the mass of monomer) and 80 ml of acetonitrile. Heating the reaction system, making the reaction system rise from room temperature to boiling state in about 30 minutes, and reacting in the boiling state for 20 minutes. After half of the solvent in the reaction system was distilled off within 1.5 hours, the reaction ended. When the reaction system kept boiling for 15 minutes, it changed from a uniform and transparent state to a turbid milky white. Polymer microspheres were gradually formed during solvent evaporation and precipitated from the reaction system. After the reaction, the polymer microspheres were separated by filtration under reduced pressure, and then the polymer microspheres were washed three times with T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com