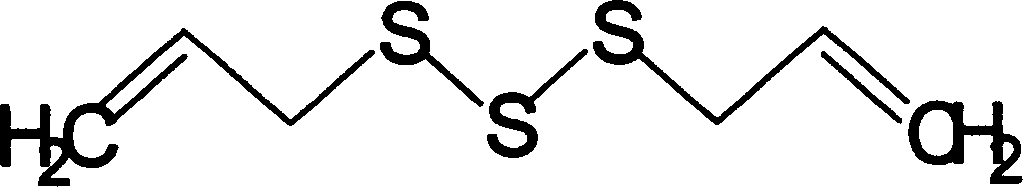

Garlicin injection emulsion and its preparing method

An allicin and injection technology, applied in the field of medicine, can solve the problems of unfavorable clinical application and storage of allicin preparations, high body irritation, insufficient stability of allicin and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation of allicin intravenous submicroemulsion injection, the prescription of this dosage form consists of:

[0033] Synthetic allicin (the content of allicin is 97.0~103.0%) 2g

[0034] Soy Lecithin for Injection 10g

[0035] Soybean oil for injection 16g

[0036] Glycerin for injection 3g

[0037] Add water for injection to 1000ml

[0038] The preparation method is:

[0039]1. Weigh the prescribed amount of allicin and add it to soybean oil for injection and mix well to form an oil phase;

[0040] 2. Weigh the soybean lecithin for injection, glycerin for injection and 100ml water for injection of the prescribed dosage, and stir to dissolve completely;

[0041] 3. Add the oil phase to the water phase under stirring, and then put it into an ultrasonic cell pulverizer to pulverize and stir to form colostrum;

[0042] 4. Transfer the colostrum into a high-pressure homogenizer and homogenize to obtain an emulsion with an average particle size o...

Embodiment 2

[0046] Embodiment 2: the preparation of allicin submicroemulsion injection, the prescription of this dosage form consists of:

[0047] Synthetic allicin (the content of allicin is 97.0~103.0%) 8g

[0048] Soy Lecithin for Injection 21g

[0049] Poloxamer 188 3.5g

[0050] Propylene glycol for injection 4g

[0051] Mannitol for injection 14.5g

[0052] Soybean oil for injection 100g

[0053] Add water for injection to 1000ml

[0054] The preparation method is:

[0055] 1. Weigh the prescribed amount of allicin and add it to soybean oil for injection and mix well to form an oil phase;

[0056] 2. Weigh soybean lecithin for injection, poloxamer 188, propylene glycol for injection, mannitol for injection, and 250ml of water for injection of the prescribed dosage, stir to dissolve completely, and make into water phase;

[0057] 3. Add the oil phase to the water phase under stirring, and then put it into an ultrasonic cell pulverizer to pulverize and stir to form colostrum; ...

Embodiment 3

[0062] Embodiment 3: the preparation of allicin submicroemulsion injection, the prescription of this dosage form consists of:

[0063] Allicin raw material medicine (the content of allicin is 81.0~87.0%) 12.5g

[0064] Soy Lecithin for Injection 15g

[0065] Tween 80 4g

[0066] Glycerin for injection 7g

[0067] Castor oil 100g

[0068] Sodium deoxycholate 2.5g

[0069] Add water for injection to 1000ml

[0070] The preparation method is:

[0071] 1. Weigh the prescribed amount of allicin and add it to castor oil for injection and mix well to form an oily phase;

[0072] 2. Weigh soybean lecithin for injection, Tween 80, glycerin for injection, sodium deoxycholate, and 500ml of water for injection of the prescription dose, stir to dissolve completely, and make into an aqueous phase;

[0073] 3. Add the oil phase to the water phase under stirring, and then put it into an ultrasonic cell pulverizer to pulverize and stir to form colostrum;

[0074] 4. Transfer the colost...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com