Preparation method of highly active titanium dioxide membrane photocatalyst

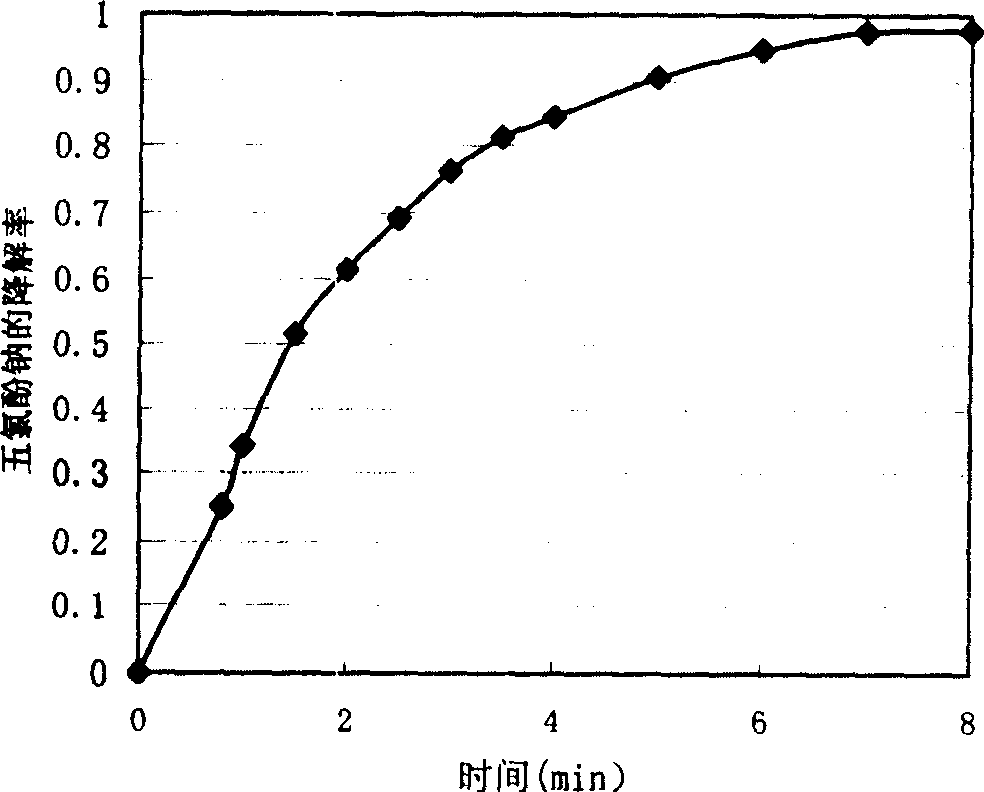

A technology of photocatalyst and titanium dioxide, which is applied in the field of water treatment technology and air treatment, can solve the problems of shortened service life and low photocatalytic activity, and achieve the effects of strong controllability, high photocatalytic activity and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Preparation of thin film photocatalyst on titanium sheet by dipping and pulling method

[0033] 1) Loading substrate material treatment: commercially pure titanium is immersed in boiling Na with pH=9.5 2 CO 3 Keep it in the solution for 30 minutes, carry out thorough degreasing treatment and rinse, and then immerse in boiling 10% oxalic acid aqueous solution, keep it for 1 hour, and carry out activation treatment. When the surface of the base material presents a uniform dark gray pitted surface and the metallic luster disappears completely, the base material can be taken out, rinsed and dried, and can be used as a base material for supporting titanium dioxide thin film photocatalysts.

[0034] The effect of oxalic acid in the present invention:

[0035] a) Oxalic acid, as a drying control chemical additive, plays a role in suppressing cracks during the film formation process (no penetrating long cracks appear on the surface of the film), so that the surface...

Embodiment 2

[0043] Embodiment 2: Prepare thin film photocatalyst on aluminum sheet by spraying method

[0044] 1) Loading base material treatment: 0.5mm-thick sheet-shaped industrial pure aluminum is immersed in boiling detergent solution with pH=9 for 30 minutes, thoroughly degreased, taken out and rinsed, and then immersed in boiling 1 % oxalic acid aqueous solution, keep 1h, carry out activation treatment. When the metallic luster on the surface of the base material disappears completely and becomes uniform off-white, the base material can be taken out, rinsed and dried, and can be used as a base material for supporting titanium dioxide thin film photocatalysts.

[0045] 2) Coating sol preparation: Add 5ml of isopropyl titanate and 2ml of acetylacetone in sequence to 70ml of ethylene glycol, stir and mix well, then slowly drop in 2ml of deionized water, and then fully disperse with ultrasonic waves for 20min, then Then add 0.1 g of oxalic acid, stir quickly to dissolve the oxalic acid...

Embodiment 3

[0049] Example 3: Preparation of thin film photocatalyst on nickel foam by dipping and pulling method

[0050] 1) Loaded base material treatment: the pore size is 30 mesh nickel foam loaded base material immersed in the boiling NaHCO of pH=9.5 3 Keep in the solution for 60 minutes, carry out thorough degreasing treatment and rinse, and then immerse in 20% oxalic acid aqueous solution at a temperature of 50°C, keep for 2.5 hours, and perform activation treatment. When the metallic luster on the surface of the base material disappears completely, and the base material becomes uniform gray-black, the base material can be taken out, rinsed, dried, and used as a base material for supporting titanium dioxide thin film photocatalysts.

[0051] 2) Coating sol preparation: Add 15ml tetrabutyl titanate and 8ml acetylacetone in sequence to 80ml glycerol, stir and mix well, then slowly drop in 7ml deionized water, then fully disperse with ultrasonic waves for 20min, and then add 5.55g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com