Sterilization algae removal anti-fungus agent and preparation method thereof

The technology of an algae antifungal agent and sodium hydroxide is applied in the field of preparation of bactericidal algae and antifungal agent, which can solve the problems of short duration of efficacy, increased dosage of pharmaceuticals, impact sterilization, etc., and achieves long duration of sterilization and economical cost. , safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

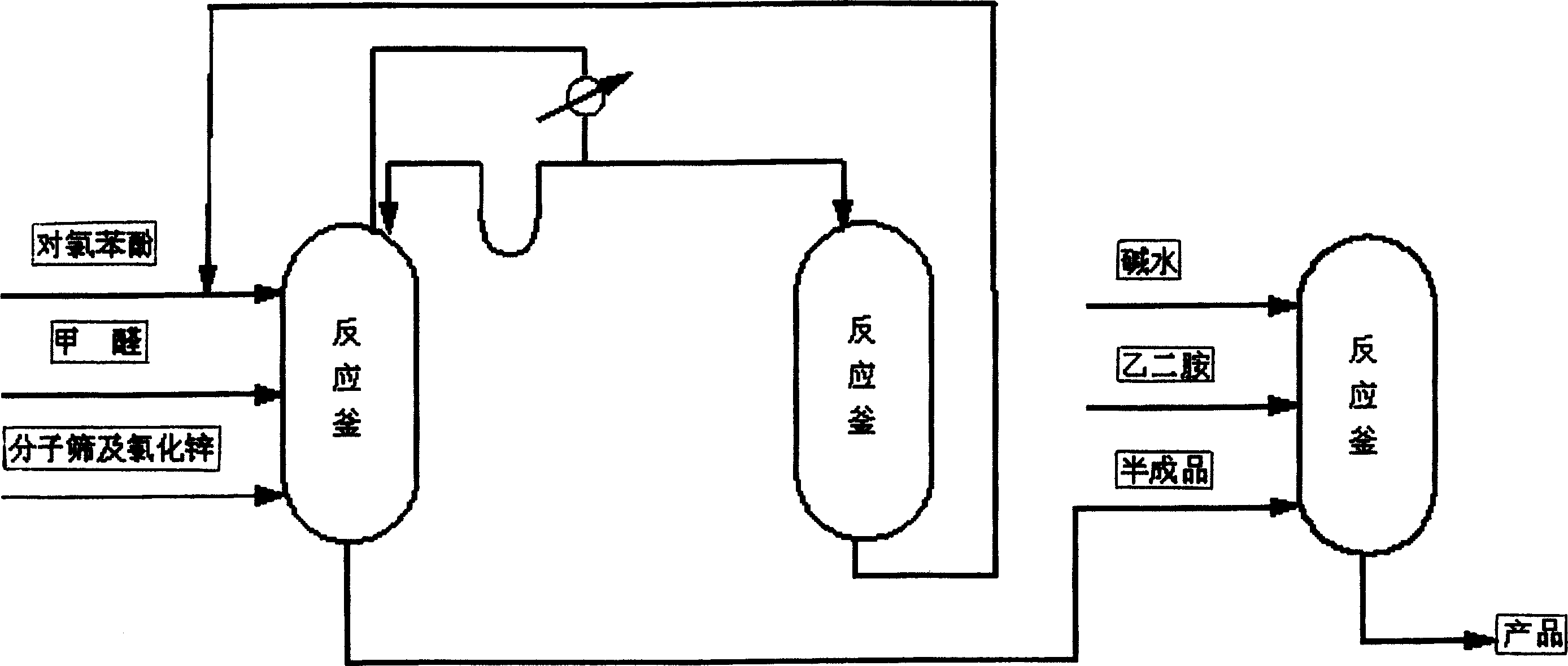

[0025] For the bactericidal algicide and antifungal agent of the present embodiment and its preparation method, see figure 1 , the steps are:

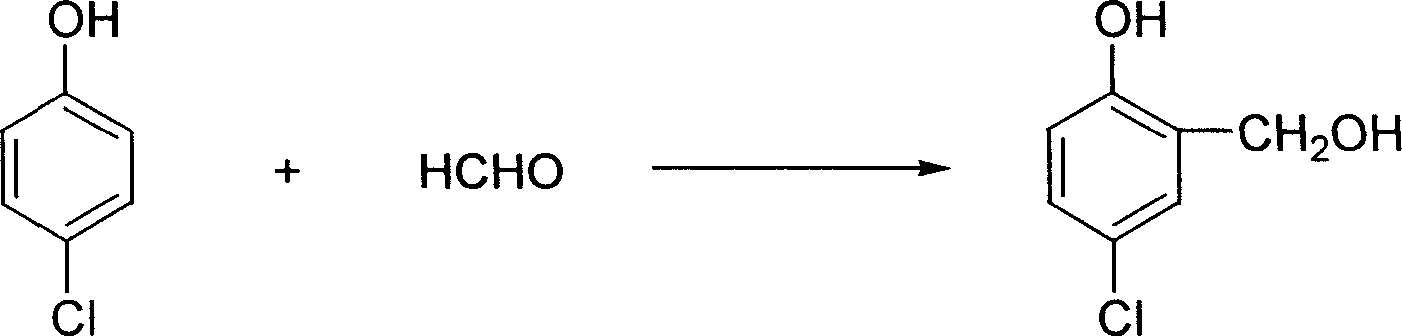

[0026] 1) Feeding: Put 417kg of molten p-chlorophenol, 41.7kg of formaldehyde, 1.9kg of molecular sieve, and 130g of zinc chloride into the condensation kettle in sequence. When pumping p-chlorophenol and formaldehyde, the vacuum degree should be controlled at 0.05MPa, and open the If the cooling water of the distillation condenser is pumped into the p-chlorophenol receiving tank, it should be released immediately and re-pumped into the condensation kettle;

[0027] 2) Heating and reflux: After the feeding is completed, close the cooling water of the distillation condenser, close the valve on the distillation column, open the reflux cooling water and the vent valve, and start stirring. After 15 minutes, turn on the heater to heat up. When the temperature rises to reflux, Control the temperature at 110°C to maintain reflux for 4 hours;...

Embodiment 2

[0032] The bactericidal algicide antifungal agent of the present embodiment and preparation method thereof are:

[0033] 1) Feeding: Put 360kg of molten p-chlorophenol, 40kg of formaldehyde, 1.2kg of molecular sieve, and 120g of zinc chloride into the condensation kettle in sequence. When pumping p-chlorophenol and formaldehyde, the vacuum should be controlled at 0.05MPa, and the distillation Condenser cooling water, if any raw material is pumped into the p-chlorophenol receiving tank, it should be released immediately and pumped into the condensation kettle again;

[0034] 2) Heating and reflux: After the feeding is completed, close the cooling water of the distillation condenser, close the valve on the distillation column, open the reflux cooling water and the vent valve, and start stirring. After 15 minutes, turn on the heater to heat up. When the temperature rises to reflux, Control the temperature at 114°C to maintain reflux for 4 hours;

[0035] 3) After the reflux, sto...

Embodiment 3

[0039] 1) Feeding: Put 440kg of molten p-chlorophenol, 40kg of formaldehyde, 2.4kg of molecular sieve, and 120g of zinc chloride into the condensation kettle in sequence. When pumping p-chlorophenol and formaldehyde, the vacuum degree should be controlled at 0.05MPa, and the distillation Condenser cooling water, if any raw material is pumped into the p-chlorophenol receiving tank, it should be released immediately and pumped into the condensation kettle again;

[0040] 2) Heating and reflux: After the feeding is completed, close the cooling water of the distillation condenser, close the valve on the distillation column, open the reflux cooling water and the vent valve, and start stirring. After 15 minutes, turn on the heater to heat up. When the temperature rises to reflux, Control the temperature at 112°C to maintain reflux for 4 hours;

[0041]3) After the reflux, stop heating, open the valve on the distillation column, close the reflux vent valve, turn on the distillation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com