Casting method of iron casting with water-cooled copper mold

A metal mold casting and water-cooled copper technology, which is applied in the field of iron castings, can solve the problems of lack of systematic research on metal mold casting technology, shorten the service life of metal molds, and affect the quality of castings, so as to reduce the auxiliary production area and reduce industrial noise , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

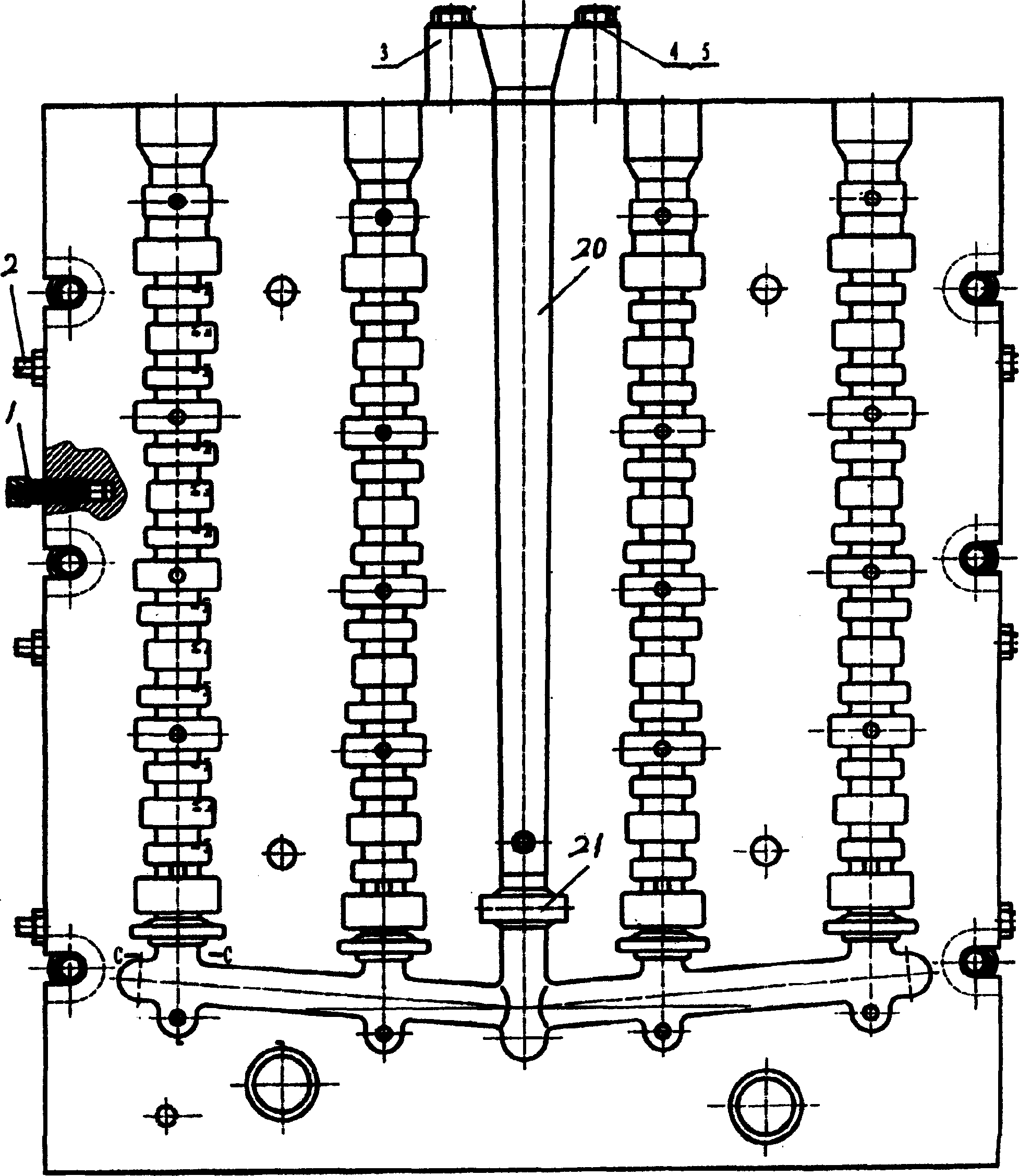

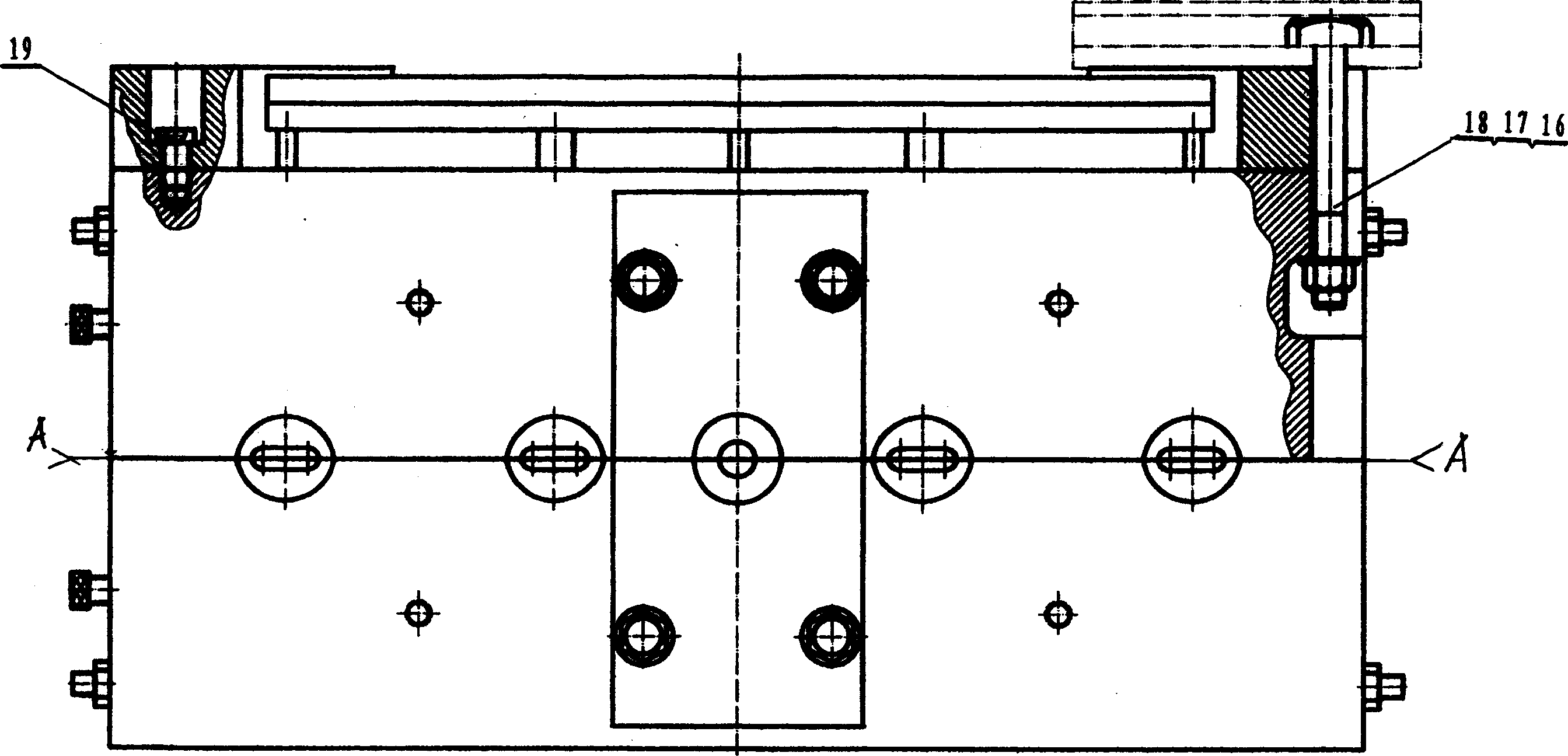

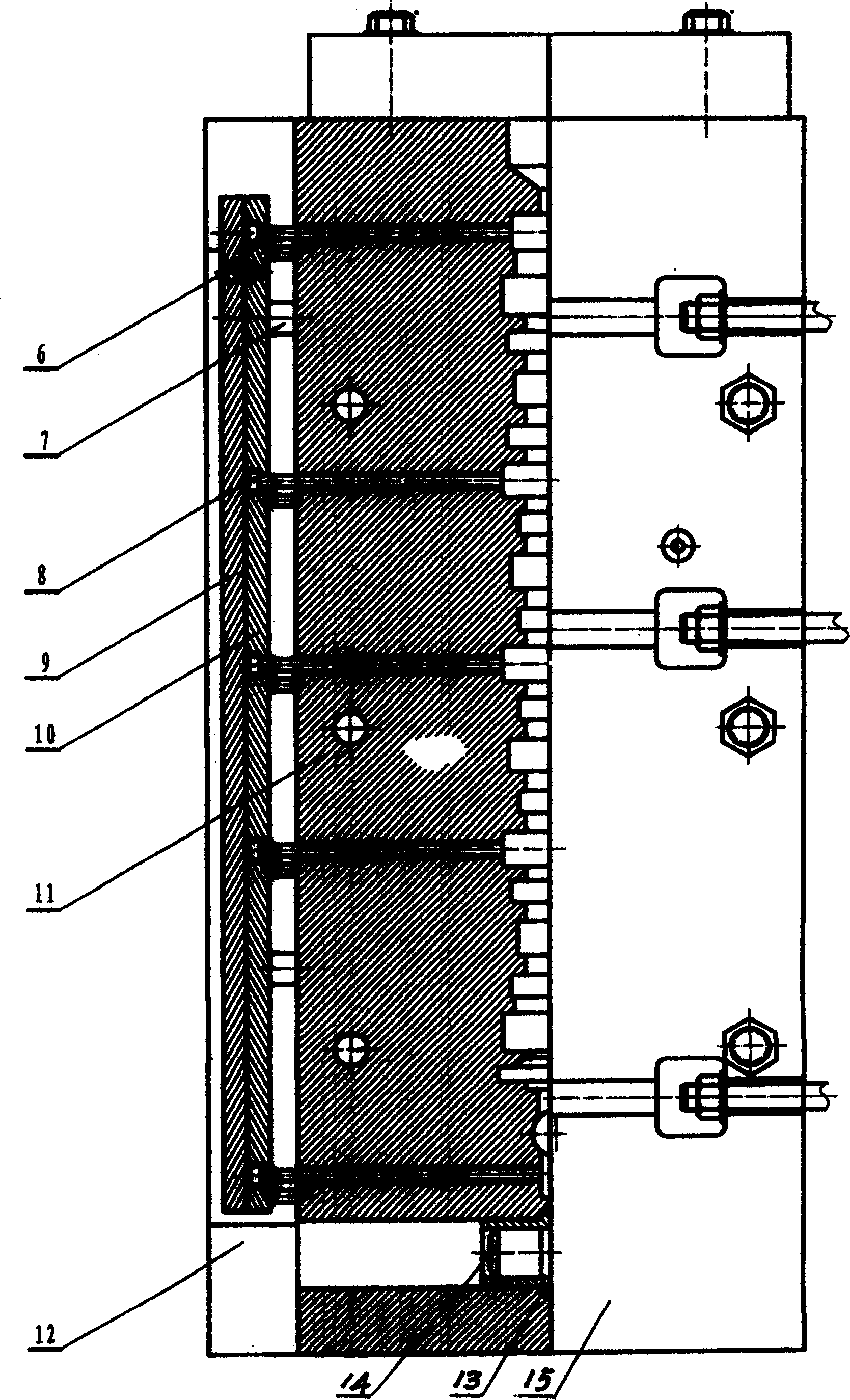

[0031] A water-cooled copper metal mold casting method for iron castings, including a molten iron melting and processing department, a metal mold casting department and a casting post-processing department. The equipment used includes a 0.5T intermediate frequency melting furnace, a 0.5T air pressure heat preservation quantitative pouring furnace, a single station metal mold casting machine, a set of central control system, a metal mold coating machine, and a heat treatment furnace , a hydraulic trimming machine, a drum type shot blasting machine and a set of ultrasonic spheroidization rate tester.

[0032] The melting of molten iron adopts KGPS-500 medium frequency induction furnace with neutral integral lining. The melting speed is 0.5T / 50-80min, and the furnace temperature is 1450-1580℃. The molten iron from the furnace enters a PPF1-100 type pressure heat preservation and quantitative pouring furnace. Inject 6kg of molten iron into the small ladle or directly inject the m...

Embodiment 2

[0036] Embodiment 2 is basically the same as Embodiment 1, and the difference is that the water-cooled metal type adopts copper-chromium alloy (Cu-Cr) or copper-chromium-zirconium-aluminum alloy (Cu-Cr-Zr-Al), and the runner ratio is ( f 直 :F 横 :F 内 ) takes 1.0:1.7:2.3. The copper-chromium alloy or copper-chromium-zirconium-aluminum metal type is used with temperature control at 215°C. The adding amount of nodulizer is 1.3%, and the adding amount of inoculant is 0.8%.

Embodiment 3

[0038] Embodiment three is basically the same as embodiment one, and its differences mainly include: the water-cooled metal type selects copper-nickel-silicon alloy (Cu-Cr-Zr), and the runner ratio is (F 直 :F 横 :F 内 ) takes 1.0:1.7:2.6. The temperature is controlled at 260°C during use. The adding amount of nodulizer is 1.8%, and the adding amount of inoculant is 1.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com