Method for extruding a continuous moulded body

A technology of forming body and extrusion channel, applied in the field of additives or adding additives in organic or inorganic form, can solve problems such as the inability to realize continuous forming body, and achieve improved physical properties of weaving, physical properties of weaving, and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

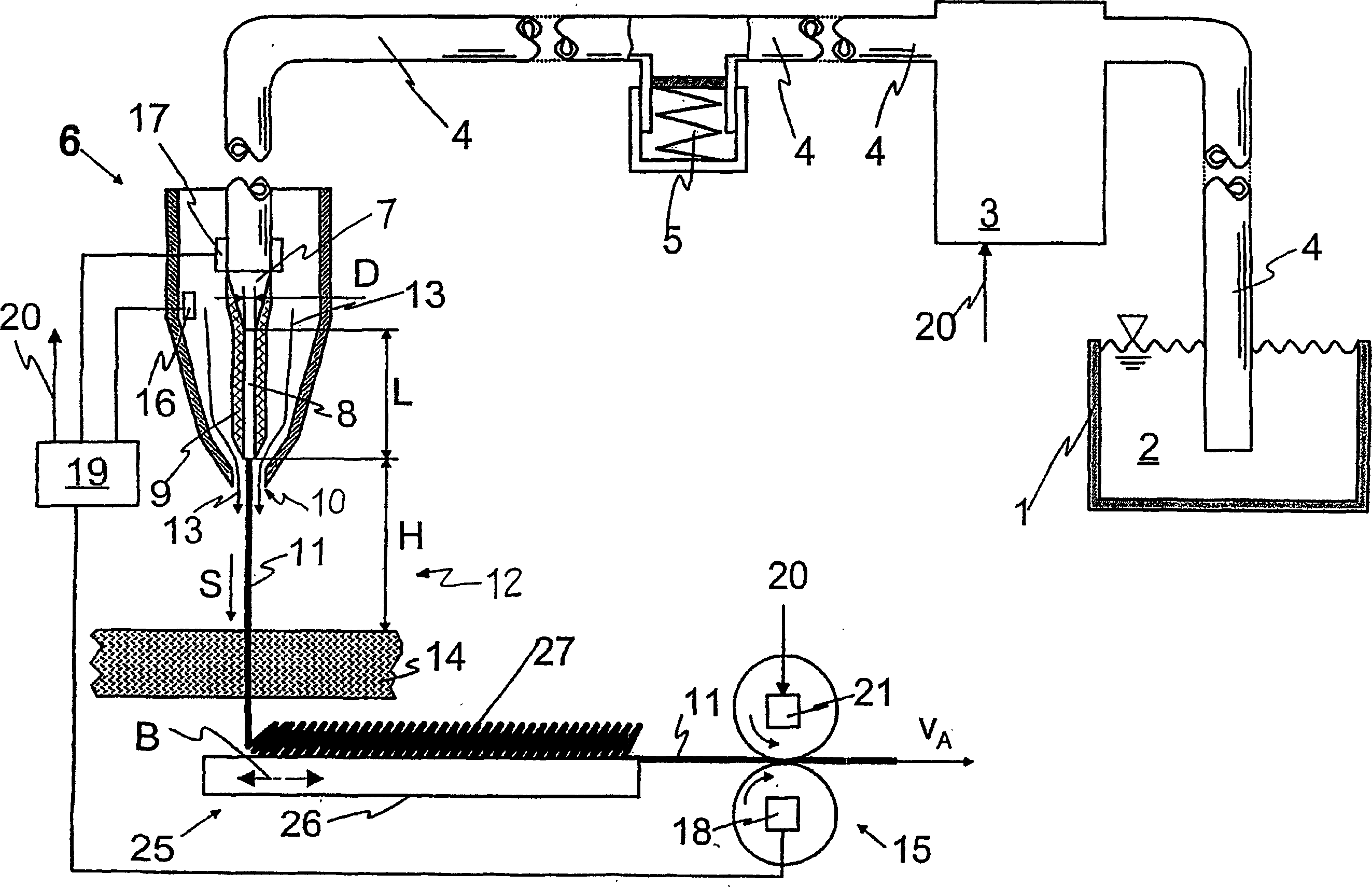

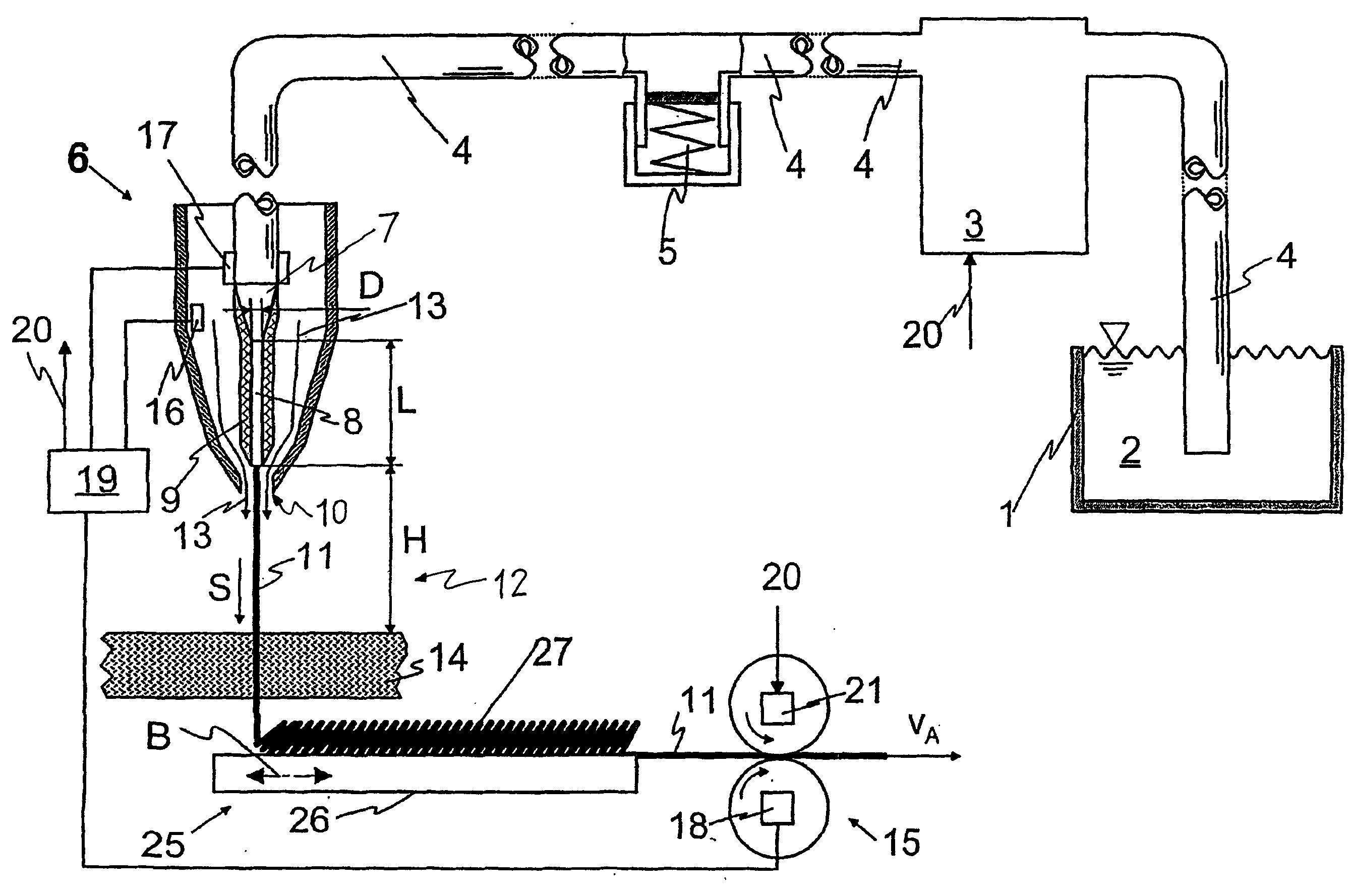

[0055] First, the sequence of the method according to the invention is described with the aid of FIG. 1 .

[0056] Squeeze solution 2 is prepared in reaction vessel 1 . The extrusion solution contains cellulose, water and a tertiary amine oxide, such as N-methylmorpholine-N-oxide (NMMO), and if necessary a stabilizer for thermal stabilization of the cellulose and solution. Stabilizers can be, for example: propyl gallate (Propylgallat), media or mixtures which have an alkalizing effect on each other. It may also contain other additives if necessary, such as titanium dioxide, barium sulfate, graphite, carboxymethyl cellulose, polyethylene glycol, chitin, chitosan, alginic acid, polysaccharides, pigments, chemical agents with bactericidal effect , Flame retardants containing phosphorus, halogens or nitrogen, activated carbon, carbon black or conductive carbon black, silicic acid and organic solvents as diluents, etc.

[0057] The extrusion solution 2 is conveyed through a pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com