Method for producing mischmetal using Mianning rare earth ore as raw material

A technology of mixed rare earth and rare earth ore, which is applied in the direction of improving process efficiency to achieve the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

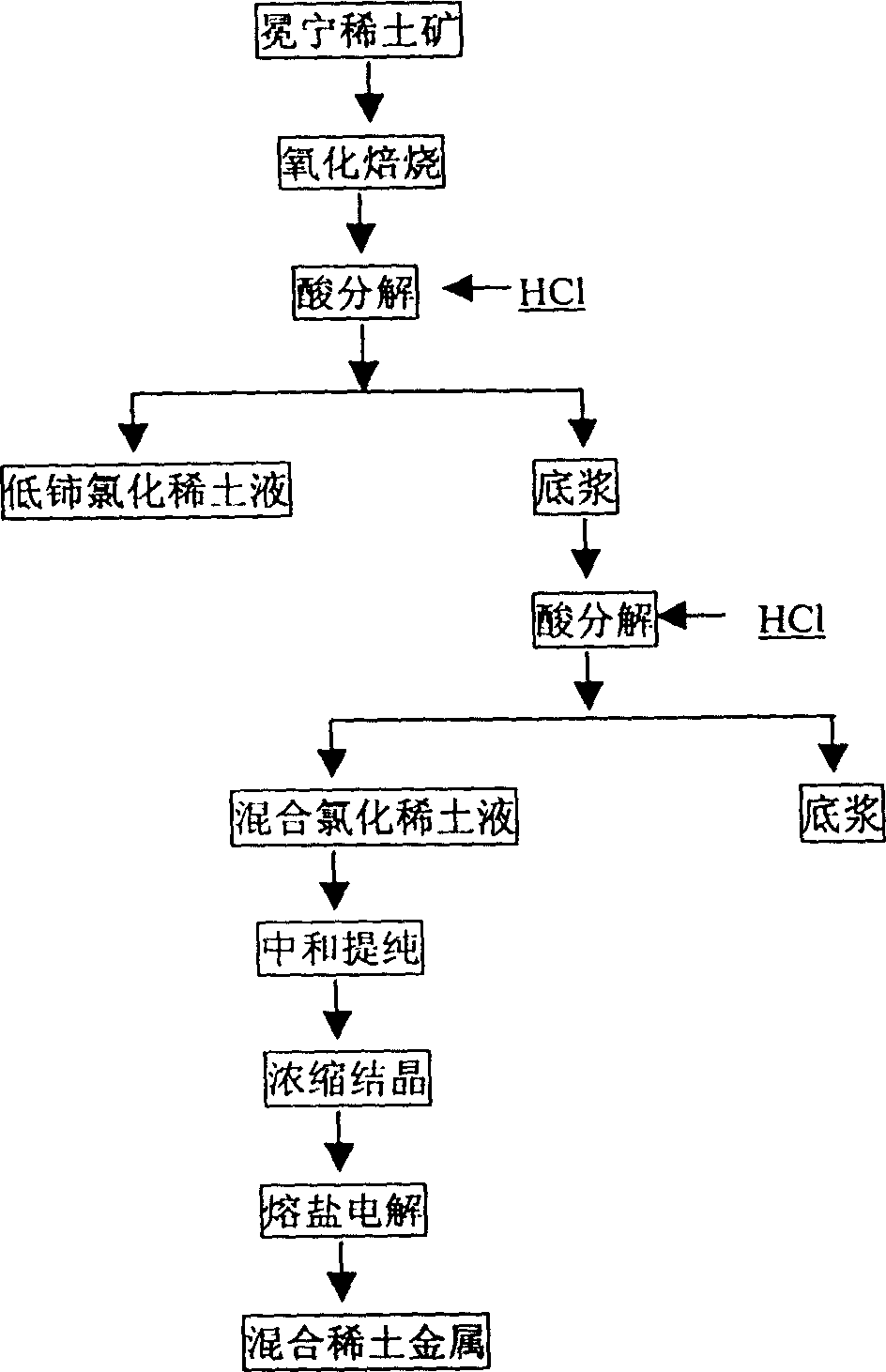

[0030] Its process flow is attached figure 1 shown. The process for preparing mixed rare earth chlorides from Sichuan Mianning rare earth mines is carried out in the following steps.

[0031] 1. Sichuan Mianning rare earth concentrate after physical beneficiation treatment is oxidized and roasted at about 550°C for about 4 hours, so that the fluorocarbonate in the rare earth ore is converted into oxide and oxyfluoride, and the non-quaternary cerium is converted into Cerium in the 4-valent state is beneficial to the separation of cerium and other rare earth components in the subsequent process.

[0032] 2. Add hydrochloric acid with a weight concentration of about 30% into the oxidized and roasted rare earth slurry to dissolve the rare earth ore so that the non-CeO in the rare earth ore 2 The rare earth components are preferentially eluted, the amount of acid used is about 0.6 times the weight of the rare earth oxide contained in the rare earth ore, the dissolution temperatur...

Embodiment 2

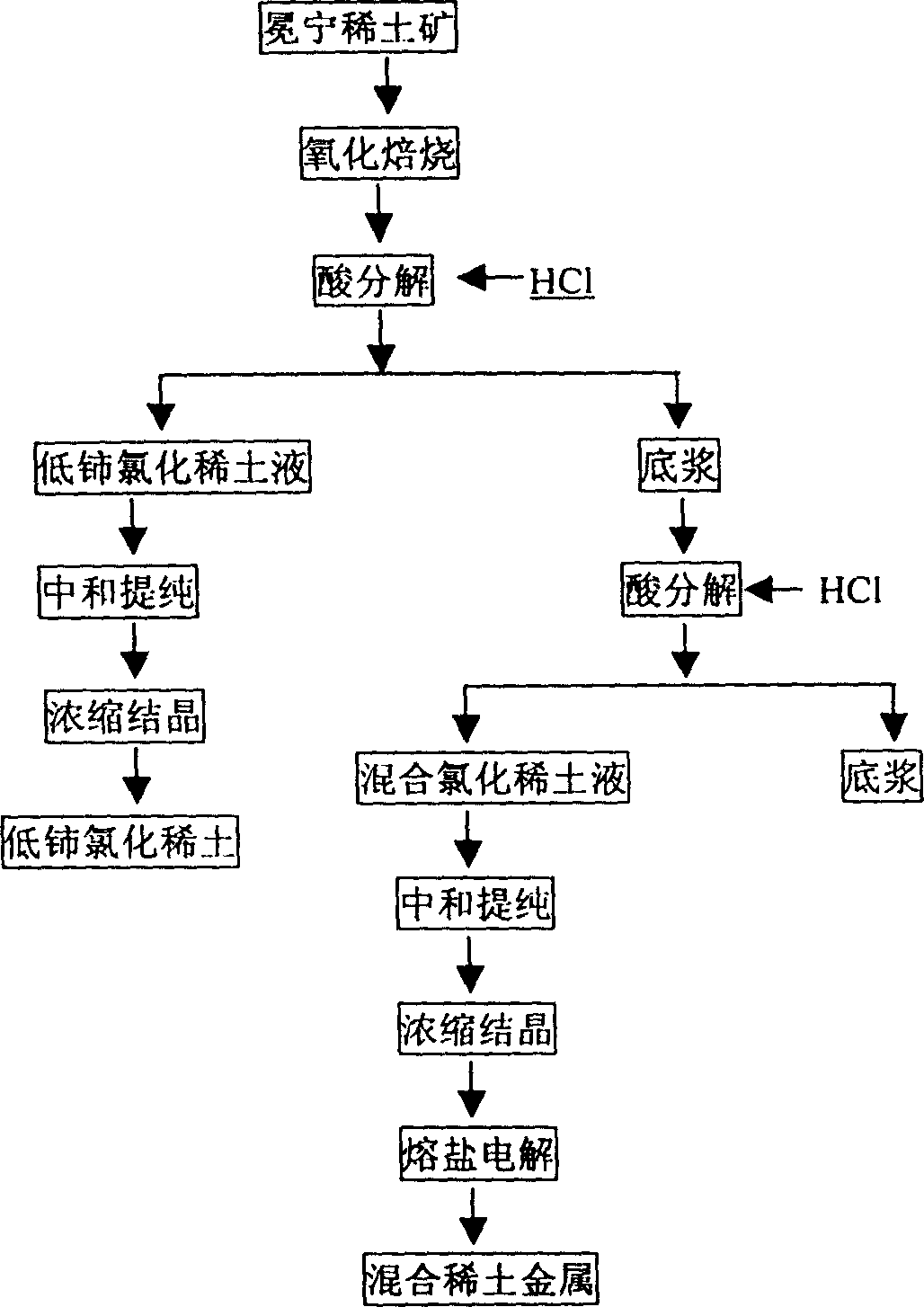

[0038] Its process flow is attached figure 2 shown. The cerium-poor mixed rare earth chloride liquid separated in the excellent melting process is heated, evaporated and concentrated, and then cooled to crystallize the rare earth in the liquid, so as to obtain a cerium-poor and lanthanum-rich mixed rare earth chloride by-product. Other parts of the process in this embodiment are the same as in Embodiment 1.

Embodiment 3

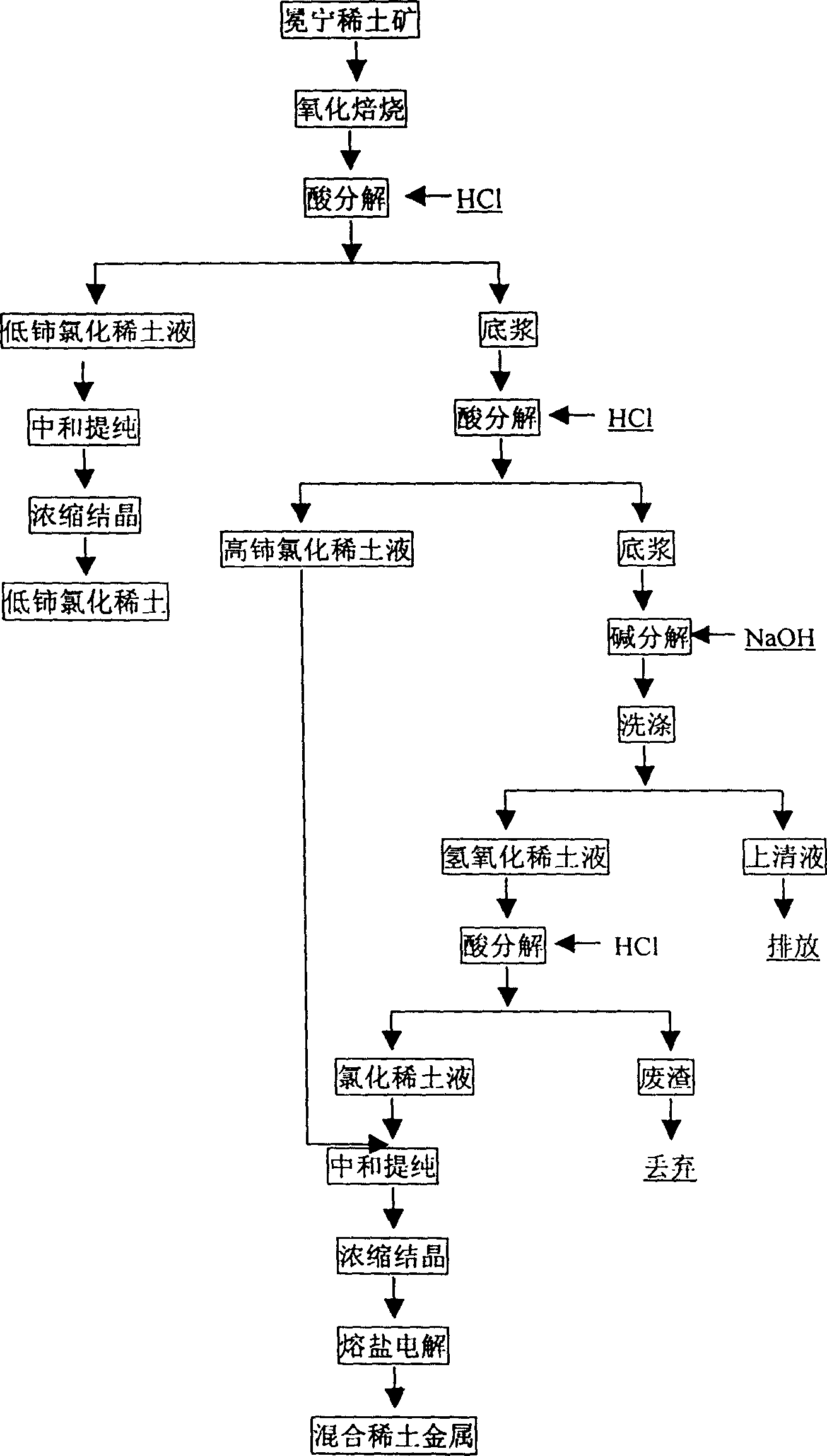

[0040] Its process is as image 3 shown. The solid-phase slag separated from the complete melting process is further processed to recover the effective rare earth components contained in it. The specific process steps are as follows:

[0041] 1. Using a sodium hydroxide solution with a weight concentration of about 35% to carry out a conversion reaction on the solid-phase slag, so that the rare earth compounds in the rare earth slag that are insoluble in acid are converted into rare earth hydroxides that are easily soluble in acid. The amount of sodium hydroxide is about 0.8 times the weight of the rare earth oxide contained in the ore, the conversion temperature is about 97 ° C, the conversion reaction time is about 3 hours, and then the solid-liquid separation is carried out by filtration, and the obtained solid phase is washed with water. , sent to the next process, and the liquid phase is discharged as waste water.

[0042] 2. Dissolving the rare earth hydroxide with hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com