Alkalophilic bacterium and production for solid state fermentation of alkali pectase from alkalophilic bacterium

An alkalophilic bacteria, solid state fermentation technology, applied in the field of bioengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1: Effects of different pectin-containing biomass and different humidity of medium on enzyme production

[0011] Add 1 times, 2 times, 3 times, 4 times water respectively in 5g (dry weight) containing pectin solid biomass, dissolve peptone 0.15g, potassium dihydrogen phosphate 0.23g, sodium carbonate 0.09g in every water, stir Uniformly, cultured statically at 35°C for 72 hours. The results are shown in Table 1.

[0012] Table 1: Effects of various pectin-containing biomass and medium humidity on enzyme production

[0013] pectin-containing biomass

[0014] Note: The enzyme activity is determined by the DN8 method, and one enzyme activity unit (u) is defined as: the enzyme required to degrade sodium polygalacturonate to produce 1 μmol of galacturonic acid per minute under the reaction conditions of 55°C and pH 10.5 amount.

Embodiment 2

[0015] Embodiment 2: the influence of different nitrogen sources on producing enzyme

[0016] Add 3 times the weight of the nutrient solution to the sugar beet meal, the composition of the nutrient solution is: 1.0% of different nitrogen sources, 0.15% of potassium dihydrogen phosphate, and 0.6% of sodium carbonate. Sugar beet pulp and nutrient solution were sterilized at 115°C for 15 minutes respectively, mixed uniformly at a weight ratio of 1:3, inoculated with liquid seeds, and cultured statically at 35°C for 72 hours. The results are shown in Table 2.

Embodiment 3

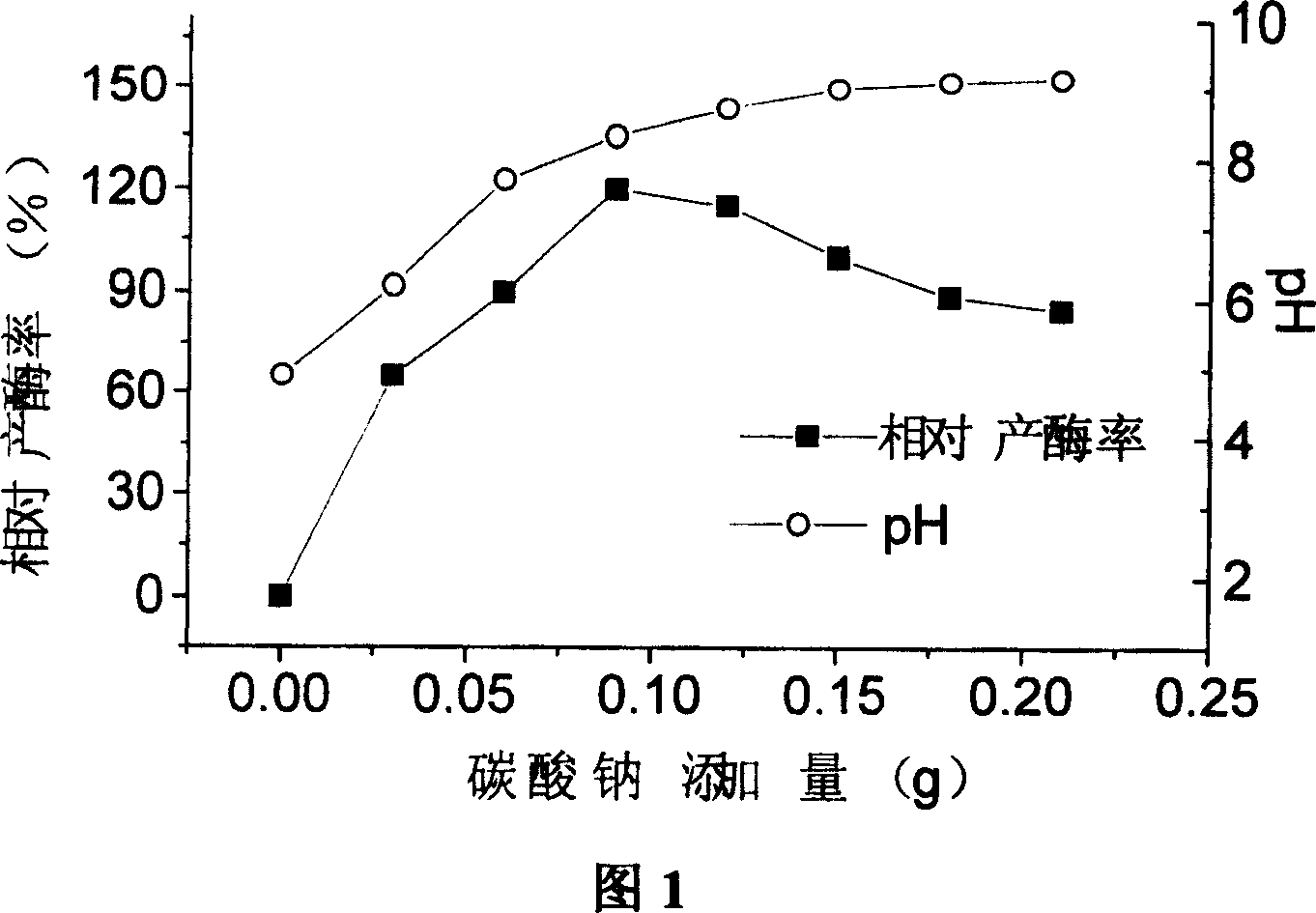

[0017] Embodiment 3: the impact of different sodium carbonate additions on producing enzyme

[0018] Add 15 milliliters of nutrient solution to 5 grams of sugar beet meal, and the composition of the nutrient solution is: 1.0% of yeast extract, 0.15% of potassium dihydrogen phosphate, and 0-1.5% of sodium carbonate. Sugar beet pulp and nutrient solution were sterilized at 115°C for 15 minutes respectively, mixed uniformly at a weight ratio of 1:3, inoculated with liquid seeds, and cultured statically at 35°C for 72 hours. The results are shown in Figure 1. When the sodium carbonate is 0.6%, the enzyme production rate is the highest, reaching 3500 units / g dry vegetable dregs.

[0019] Table 2: Effects of different nitrogen sources on enzyme production

[0020] nitrogen source

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com