Novel rhodococcus, rhodococcus-origin nitrilase gene, nitrilehydratase gene and amidase gene and process for producing carboxylic acids by using the same

A Rhodococcus genus, a technology for producing carboxylic acid, applied in the field of novel Rhodococcus bacterium, nitrilase gene, nitrile hydratase gene and amidase gene derived from Rhodococcus bacterium, and the production of carboxylic acid using them, It can solve the problems of unclear genes and low activity of nitrile hydratase and amidase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] The acquisition of embodiment 1 microorganism variant

[0127] Rhodococcus strain ATCC39484 (from the American Type Culture Collection) was streaked onto LB agar medium and incubated at 30° C. for 24 hours in a constant warm bath. An inoculation loop of cells was taken out from the grown colony and inoculated into 5 ml of LB liquid culture, and cultured at 30° C. with a shaker for 6 hours. Cells were recovered by centrifugation at 10,000 g, washed three times with an equal volume of 50 mM potassium / sodium phosphate buffer (pH: 7.0), and resuspended in the same equal volume of buffer.

[0128] A 2000 ppm NTG (N-methyl-N'-nitro-N-nitrosoguanidine) solution was added to the cell suspension to make a final concentration of 100 ppm. After thorough stirring, the solution was kept at room temperature for 30 minutes. Then, the cells were recovered by centrifugation at 10000 g, washed once with the same buffer and resuspended in a small amount of the same buffer. Then, the en...

Embodiment 2

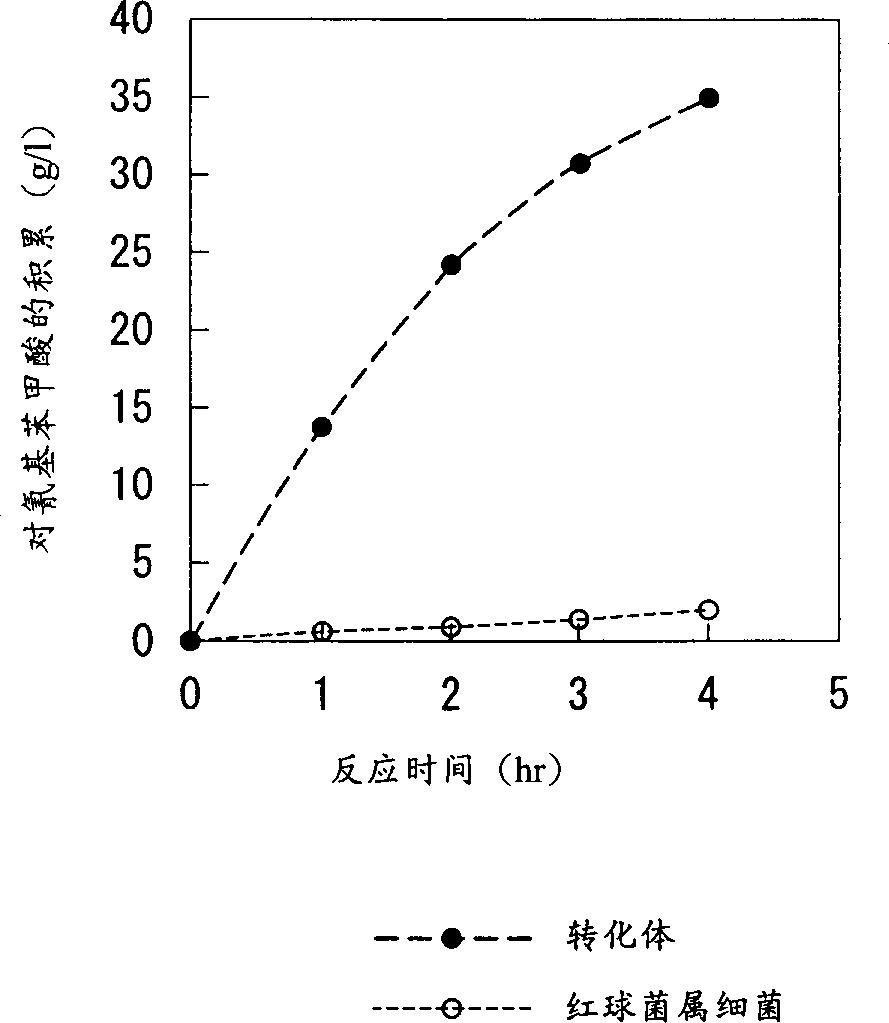

[0142]Rhodococcus SD826 was streak-inoculated on LB agar medium, and cultured in a constant temperature water bath at 30°C for 24 hours. An entire loop of cells was picked from the resulting colonies, and they were suspended in 100 ml of LB liquid medium in a 500 ml baffled flask. The flask was placed in a constant temperature shaker at 30°C and incubated at a speed of 120 rpm for 24 hours. The resulting microbial cells were recovered by centrifugation at 10,000 g and suspended in a 50 mM sodium / potassium phosphate buffer (pH 7) equal in volume to the culture medium. Add 5% (mass / volume) isophthalocyanine to the cell suspension, place the suspension in a constant temperature shaker at 30° C., and react at a speed of 120 rpm for 72 hours.

[0143] The resulting reaction solution was adjusted to pH 2 with 2 mol / l hydrochloric acid, an equal volume of ethyl acetate was added to the reaction solution, and the resulting solution was stirred and extracted. The obtained ethyl aceta...

Embodiment 3

[0148] Rhodococcus strain SD826 was streaked onto LB agar medium and cultured at 30° C. in a constant warm bath for 24 hours. A loop of cells was removed from the grown colony and inoculated into 100 ml LB liquid culture in a 500 ml baffled shake flask. The shake flasks were placed in a constant temperature shaker at 30°C and incubated at 120 rpm for 24 hours. The microbial cells were recovered by centrifugation at 10,000 g and suspended in a 50 mM potassium / sodium phosphate buffer (pH: 7.0) equal in volume to the culture solution.

[0149] As an induction substrate, isophthalocyanine was added to the cell suspension in an amount corresponding to 1% (mass / volume) and 0.1% (mass / volume) benzonitrile. Then, the suspension was placed in a constant temperature shaker at 30° C., and reacted at a speed of 120 rpm for 72 hours. The pH of the obtained reaction liquid was adjusted to 2 with 2 mol / l hydrochloric acid, an equal volume of ethyl acetate was added to the reaction liquid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com