Laser surface hardening process of gear

A surface strengthening and gear technology, applied in the field of laser surface hardening technology, can solve the problems of high cost, unstable hardened layer quality, poor quenching effect at the top of the tooth, etc., to achieve improved service life, rapid self-cooling, and strong versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

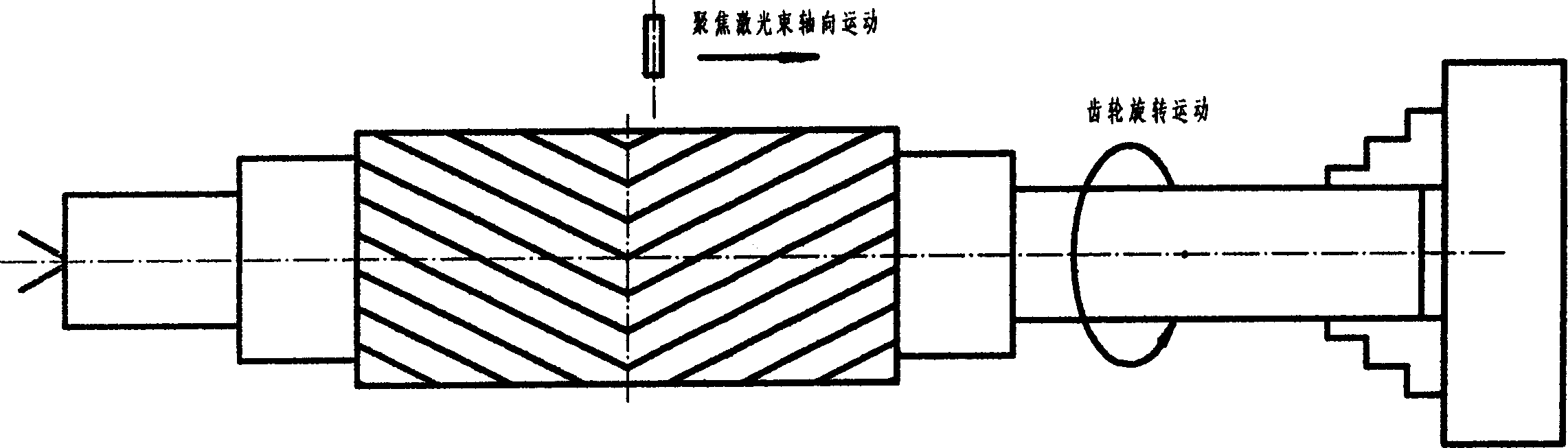

Image

Examples

Embodiment

[0034] The invention is used for the laser surface hardening treatment of the tooth surface of the herringbone gear shaft of a certain wire rolling mill production line combined with a reducer. The material of the gear is 34CrNiMo, and the quenched and tempered hardness of the matrix is HB300-320. Gear modulus Mn=16mm, number of teeth Z=22, helix angle β=26.83°. The laser treatment machine used in the present invention is the GFT-II laser heat treatment machine (with four-axis three-linkage numerical control system) produced by Guangzhou Futong Company. It proceeds as follows:

[0035] (1) The surface of the gear to be treated is cleaned and coated with light-absorbing paint;

[0036] (2) Use the laser beam to scan the surface of the gear tooth profile, so that the surface layer of the tooth profile can be quickly heated above the phase transition temperature;

[0037] (3) The laser beam leaves the tooth profile surface of the gear, and the gear itself is rapidly cooled an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com