Process for treating sewage by bipolar oxidizing and electrochemical method

A waste water treatment and electrochemical technology, applied in the direction of electrochemical water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as internal friction, complex cathode structure, etc., to improve treatment efficiency and reduce treatment energy consumption , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

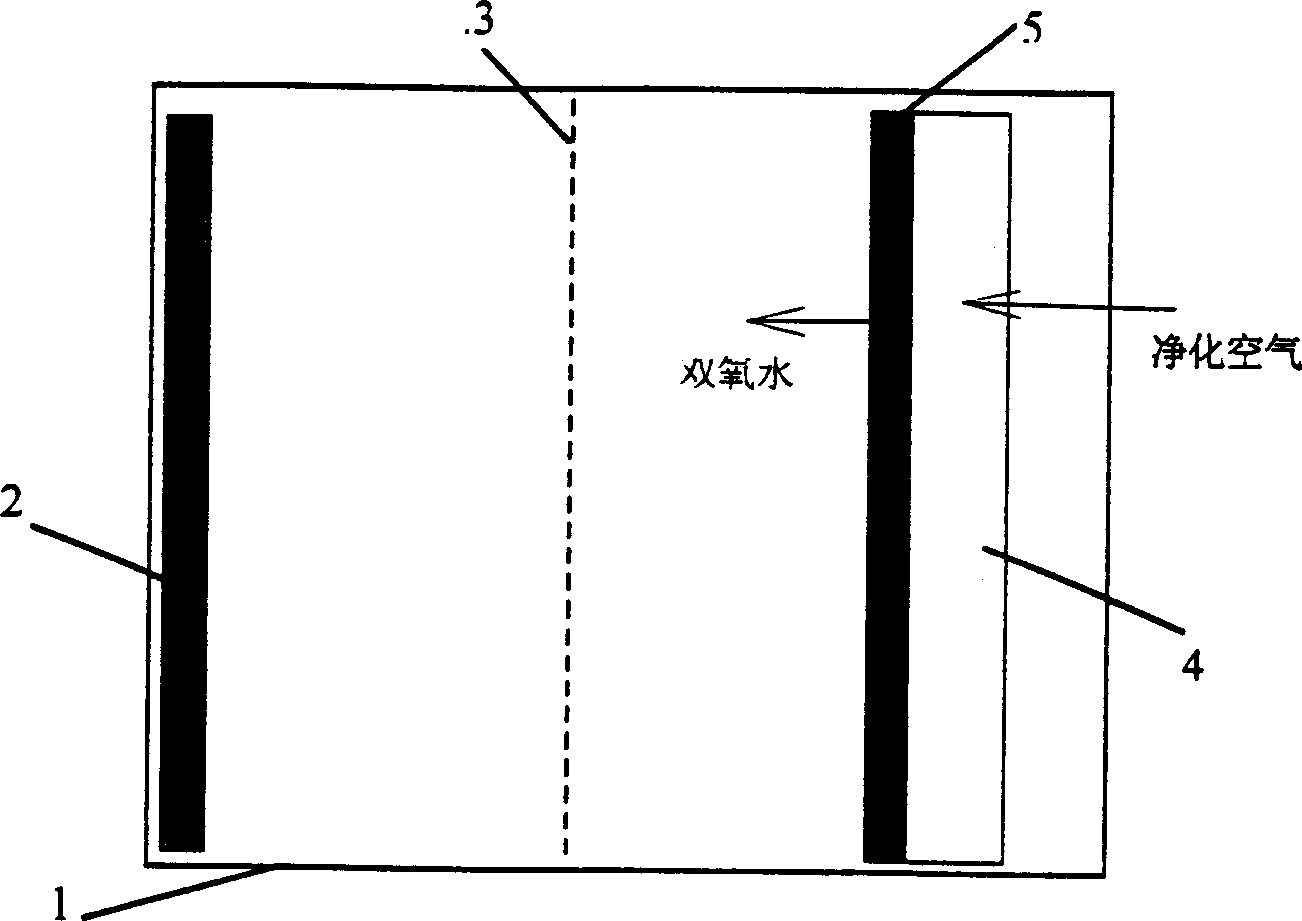

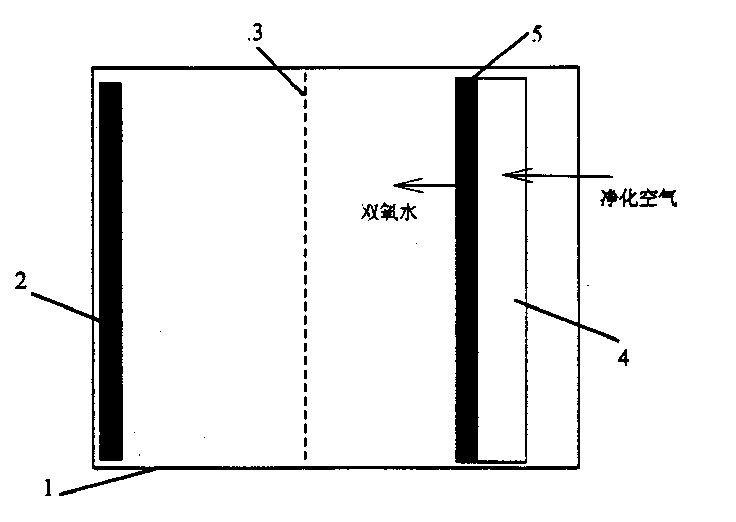

[0017] The technical solutions of the present invention will be further described below in conjunction with specific embodiments. Embodiment 1: the decolorization effect of bipolar oxidation

[0018] The membrane electrode of this embodiment is prepared by using graphite fiber as the conductive and supporting framework, carbon black as the diffusion layer and Pt element as the catalytic material. The membrane electrode is used as the cathode, the graphite electrode is used as the anode, and the saturated potassium sulfate is used as the salt bridge to connect the anode area and the cathode area. Electrolyzed acid red B is made into a certain concentration of simulated wastewater and 0.005M sodium sulfate as the dielectric, with a voltage of 8V, and the gas flow per square meter of the membrane electrode is 36m 3 / hr, samples were taken and analyzed at different reaction times, the absorbance was measured at 510nm, and the treatment effect under different pH conditions.

[00...

Embodiment 2

[0023] pH=10 45.2 3.5 Example 2: Current efficiency of bipolar oxidation

[0024] In this embodiment, graphite fiber is used as the conductive and supporting framework, carbon black is used as the diffusion layer, and a membrane electrode is prepared as the cathode. Ti / PbO 2 The electrode is the anode, and the cation exchange membrane is the separator. Electrolyzed Acid Red B to make a certain concentration of simulated wastewater, and control the current density to 1.0-3.0mA / cm 2 , the ventilation rate per square meter membrane electrode is 20m 3 / hr, samples were taken and analyzed at different reaction times, and the COD values of the cathode area and the anode area were measured before and after treatment.

[0025] COD removal rate current efficiency (%)

[0026] Voltage (V) Current mA (%)

[0027] Anode area 10.0 58 56.2 66.4

[0028] Cathode area 10.0 58 66.8 78.9

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com