Composite carbon electrode for rechargeable lithium-based batteries

An electrode and composite material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low first cycle efficiency electrodes, and achieve the effects of good cycle capacity, high specific capacity, and good rated capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

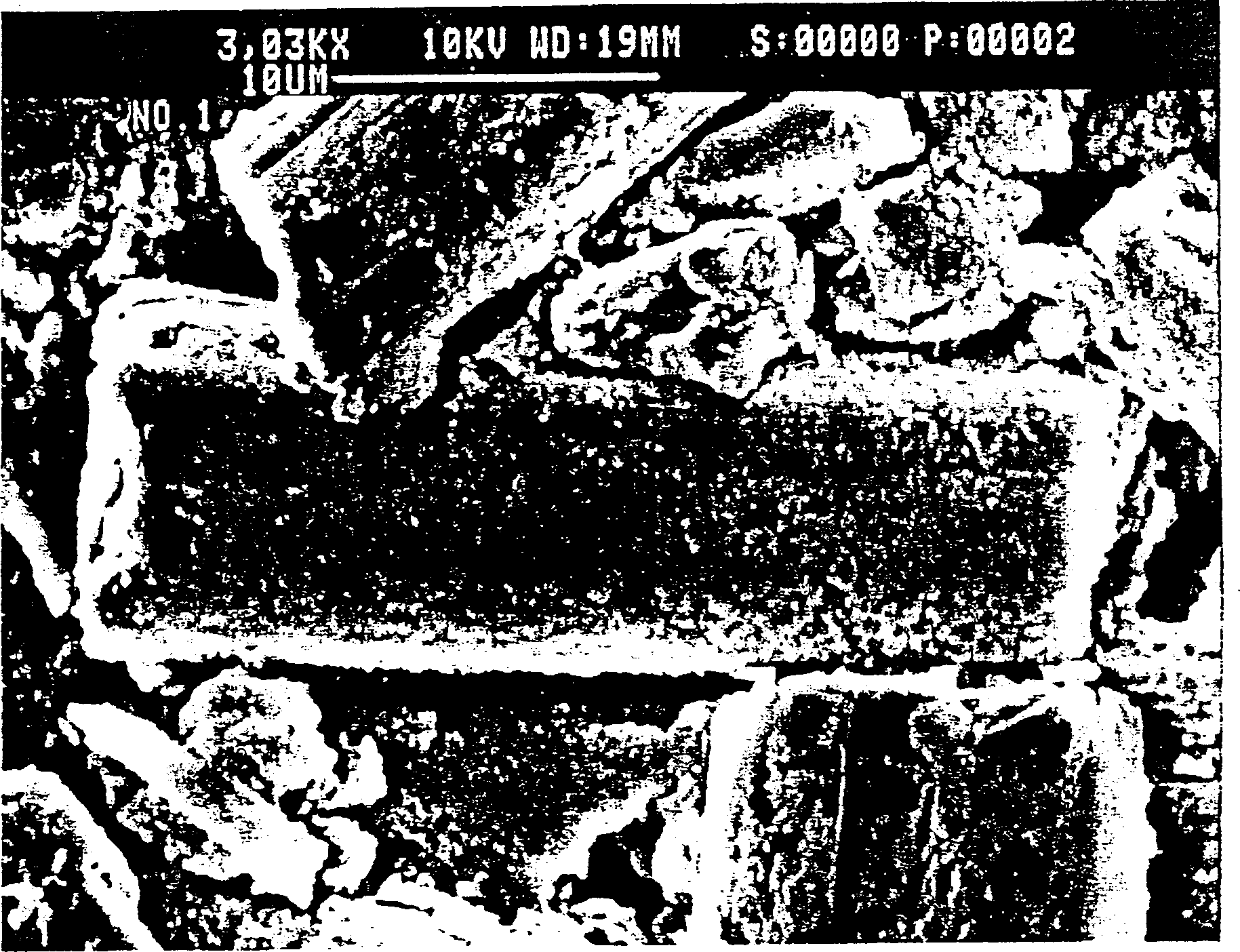

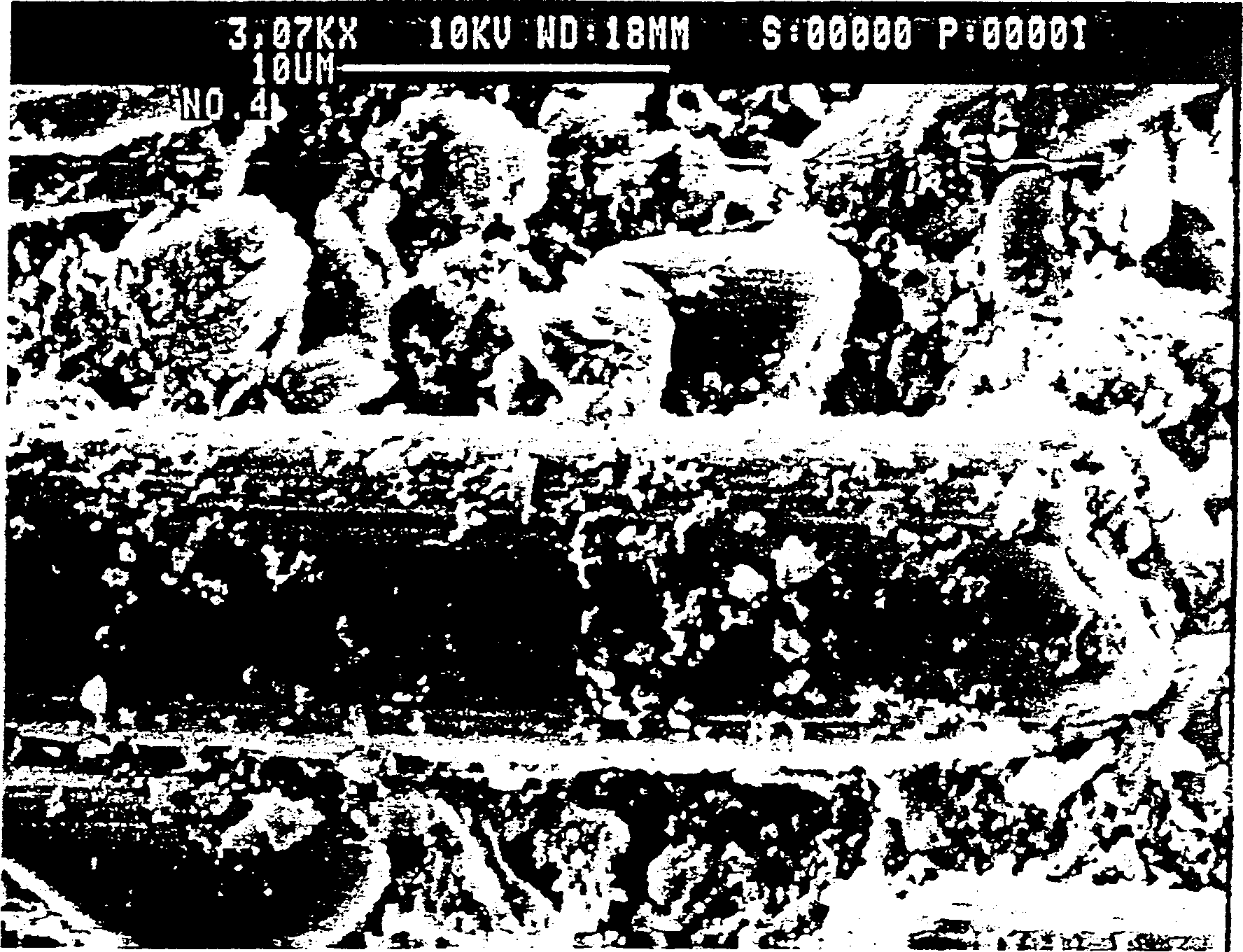

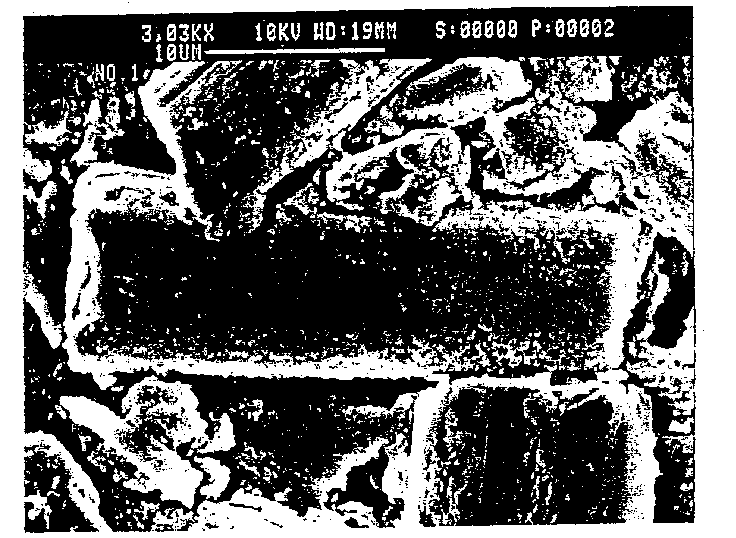

Image

Examples

Embodiment 1

[0035] 47 g of Petoca M5161 Carbon fiber (active material), 0.5 g Cabot carbon black Black Pearls 2000 (conductive additive), 31.25 grams of 15% by weight PVDF / NMP solution and 40 grams of NMP were added to a 250-ml tank equipped with 50 iron balls (φ=1 / 4 inch). The mixture was mixed through paint shaking for 40 minutes.

[0036] The slurry was coated on copper foil (~20 μm thick) using a doctor blade with a 250 μm thick wet coating. The coated electrode was heated at 150°C for 20 minutes. Electrode thickness with copper collectors is typically 100 μm.

[0037] Cut the electrodes into 3.5×4cm 2 of the article. Then at room temperature at 1000kg / cm 2 The apparent pressure of these strips was pressed with a roll press. After pressing, the thickness of the electrode with collector is typically 80 µm. The pressed electrodes were cut into discs with a diameter of approximately 0.75 cm. The weight of the active material in the disc electrode was 15 mg. The electrodes w...

Embodiment 2

[0041] In addition to the conductive additive is a surface area of 254m 2 / g and Cabot carbon black Vulcan XC 72R with a particle size of 30nm In addition, all steps are similar to the above-mentioned embodiment. Comparative example A

Embodiment 3

[0047] 48.45 grams of graphitized carbon fiber (active material) from mesophase pitch (Conoco Inc.) solvate, 0.3 grams of Cabot carbon black Black Pearls 2000 (conductive additive), 8.33 grams of 15wt% PVDF / NMP solution and 50 grams of NMP were added to a 250-ml tank equipped with 50 iron balls (φ=0.64 cm (1 / 4 inch)). The mixture was mixed for 40 minutes using a paint shaker.

[0048] The slurry was coated onto copper foil (~20 μm thick) using a doctor blade with a 250 μm thick wet coating and the coated electrode was heated at 130° C. for 30 minutes. Electrode thickness with copper collectors is typically 100 μm.

[0049] Cut the electrodes into 3.5×4cm 2 of the article. Then at room temperature at 1000kg / cm 2 The apparent pressure of these bars was pressed with a roll press. The thickness of the electrode with the collecting electrode after pressing is generally 80 μm. The pressed electrodes were cut into discs with a diameter of -0.75 cm. The weight of the active m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com