Method for preparing water-soluble nano particles

A nano-particle, water-soluble technology, applied in the interdisciplinary field of disciplines, can solve the problems of poor stability, easy agglomeration, and long time required for water-soluble nano-quantum dots, and achieve low cost, simple method, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

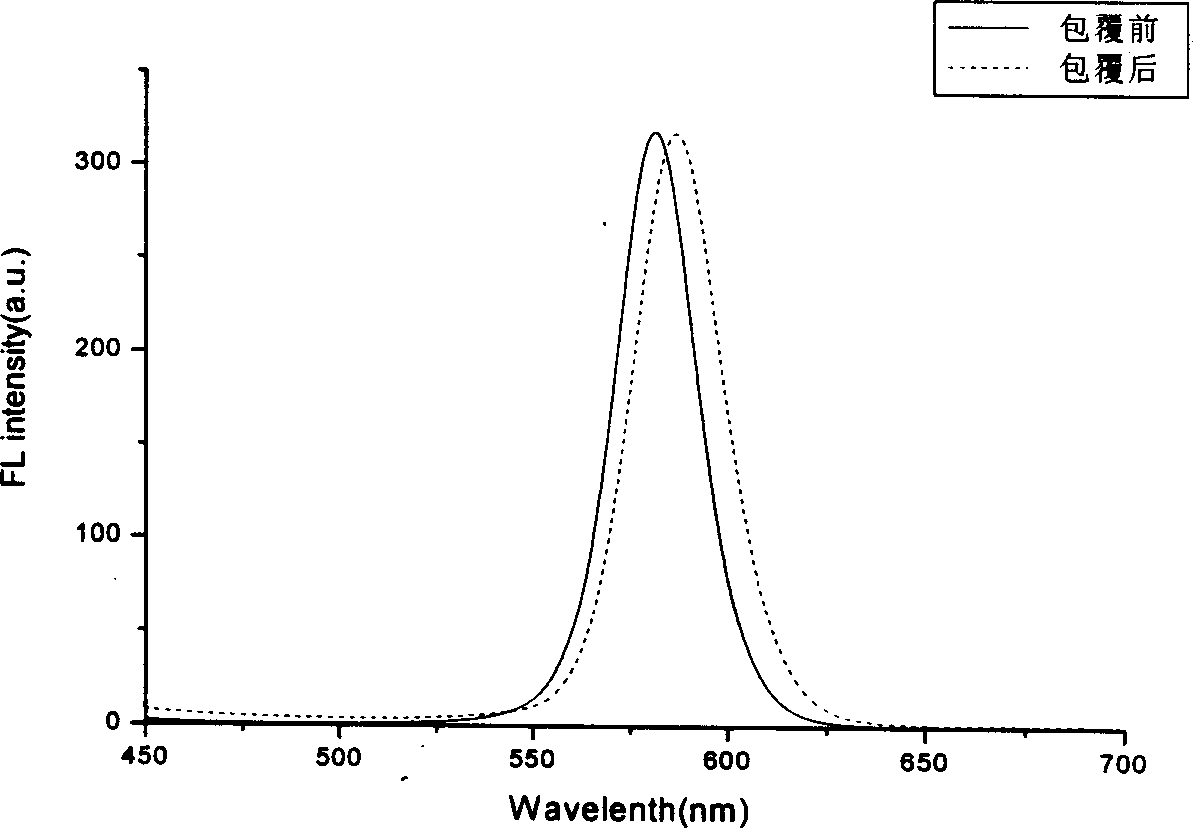

[0020] The technical scheme of the present invention is further described in conjunction with specific examples. Example 1: Water-soluble semiconductor nanometer quantum dots are used as copper ion selective probes

[0021] (1) Preparation of ZnS-coated CdSe core-shell quantum dots

[0022] Using CdO and Se powder as raw materials, CdSe quantum dots were prepared by the method in the literature. ZnS-coated CdSe core-shell quantum dots are synthesized by a new method we explored (this method has applied for a patent). The transmission electron microscope (TEM) image shows that the particle size distribution of the synthesized core-shell quantum dots is uniform, and the diameter is about 5nm. The quantum yield of quantum dots synthesized in different batches is between 60% and 85%.

[0023] (2) Preparation of bovine serum albumin (BSA)-coated water-soluble quantum dots

[0024] The ZnS-coated CdSe core-shell quantum dots dispersed in n-hexane were precipitated with methanol, ...

Embodiment 2

[0027] Nano Fe dispersed in n-Hexane 3 o 4 Synthesized according to the method in the literature [Sun S H. Zeng H. J. Am. Chem Soc. 2002, 124: 8204-8205]. Nano-Fe dispersed in n-hexane 3 o 4 Precipitate with ethanol, and wash with ethanol 2-3 times to remove excess organic molecules on the surface, take about 2mg of nano-Fe 3 o 4Re-disperse in 0.5mL n-hexane solution, then put about 50mg bovine serum albumin (BSA) and n-hexane solution together into the mortar, moderately grind to mix evenly, add 4mL PBS after the n-hexane is completely volatilized (pH7.4) buffer solution to dissolve it, centrifuge the solution at a speed of 18000 rpm, discard the supernatant, remove excess BSA, wash the precipitate with a small amount of PBS buffer solution, and then redissolve in PBS buffer solution, Centrifuge at a speed of 5000 rpm to remove agglomerated nano-Fe 3 o 4 . The upper layer is water-soluble nano-Fe coated with BSA 3 o 4 solution. Figure 10 is the prepared water-solu...

Embodiment 3

[0029] Precipitate the CdSe / ZnS core-shell quantum dots dispersed in toluene with methanol, wash with methanol 2-3 times to remove excess organic molecules on the surface, dry them under the protection of Ar, take about 1mg and redisperse them in 0.5 mL of toluene solution, then put 5 mg of immunoglobulin (IgG) and the toluene solution of quantum dots into a mortar, grind them moderately to mix them evenly, and add 2 mL of PBS (pH7.4) buffer solution after the toluene is completely volatilized , to dissolve it, centrifuge the solution at 18000 rpm, discard the supernatant, remove excess immunoglobulin, wash the pellet with a small amount of PBS buffer solution, then redissolve in PBS buffer solution, and centrifuge at a lower rpm , to remove the agglomerated quantum dots. The supernatant is the water-soluble CdSe / ZnS solution coated with immunoglobulin (IgG).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com