Method for bonding and encapsulating plastic biochip and its device

A biochip and packaging method technology, which is applied in biochemical equipment and methods, microbial determination/inspection, biological testing, etc. It is difficult to guarantee and other problems to achieve the effect of easy computer automatic control, easy automatic control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content and embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

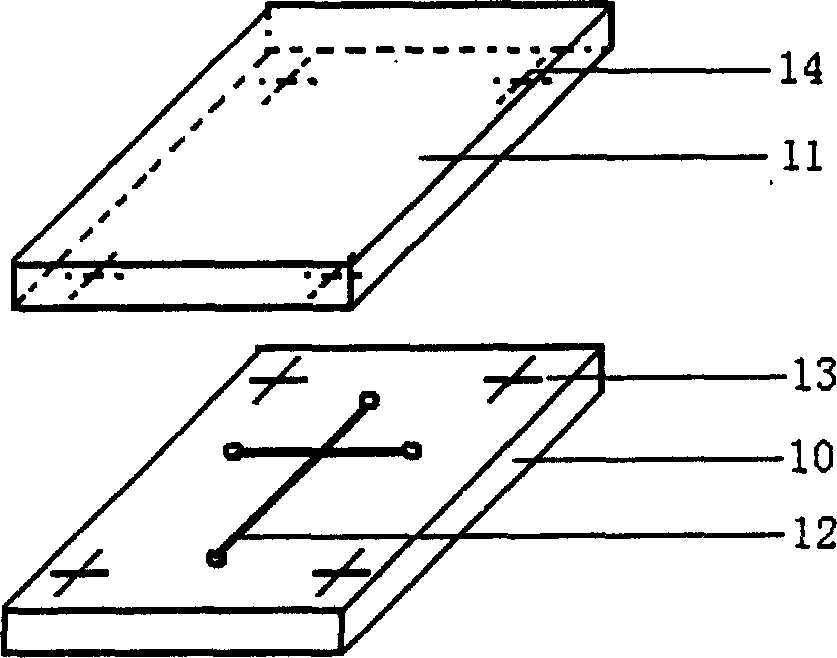

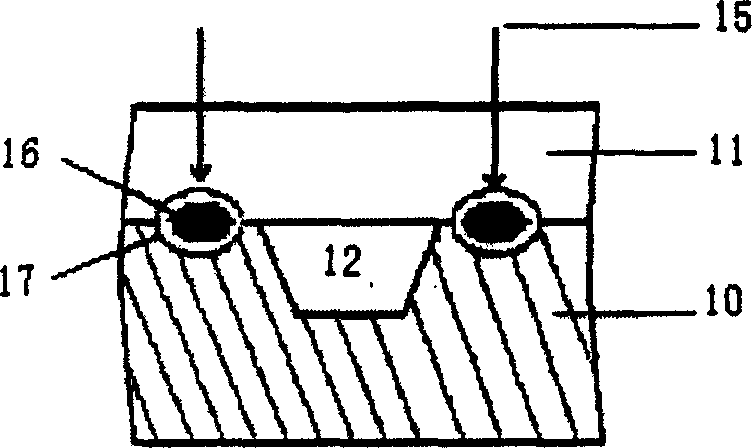

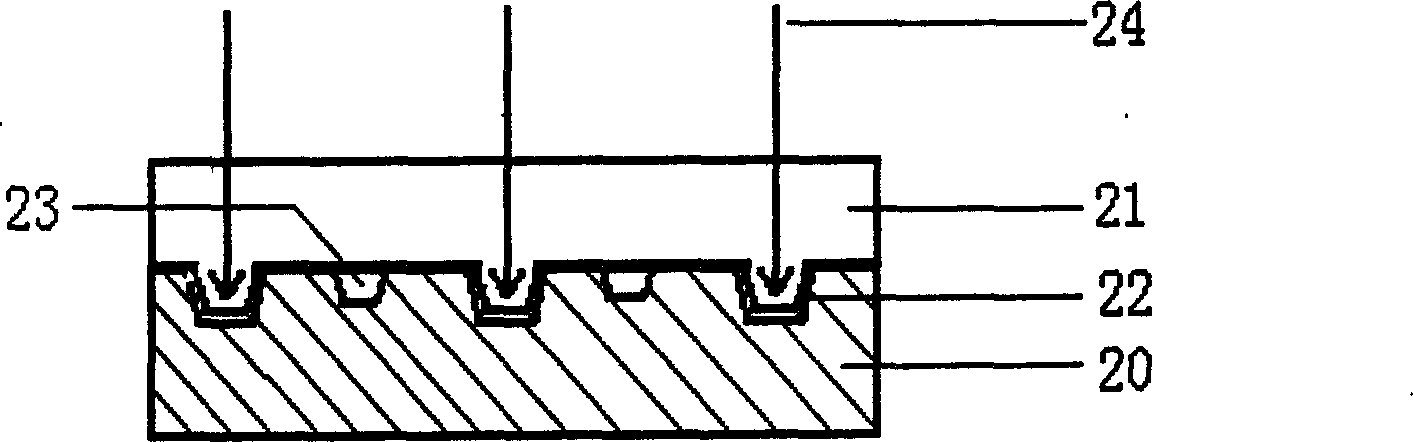

[0023] Take the typical biochip plastic microfluidic chip as an example. In FIG. 1( a ), the chip 10 and the cover 11 are fabricated separately using existing microfabrication techniques or replication techniques. The cover 11 is used to seal the microfluidic channel 12 on the chip 10 to prevent the fluid from flowing through or leaking to other areas, and at the same time play the role of isolating and protecting the chip from the outside world and providing an observation window. In order to control the accuracy of bonding and packaging, matching alignment marks 13 and 14 are respectively made on the chip 10 and the cover 11 to facilitate bonding alignment. Figure 1(B) shows a schematic diagram of the laser-bonded microfluidic channel. Laser bonding is used to bond the area around the microfluidic channel 12 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com