Semiconducting process for ceramic chip of semiconductor ceramic capacitor

A technology of ceramic capacitors and process methods, which is applied in the direction of capacitors, capacitor manufacturing, and fixed capacitor dielectrics, etc., which can solve the problems of high cost, high risk, and poor process adaptability, etc., to reduce production costs, improve economic benefits, and reduce risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

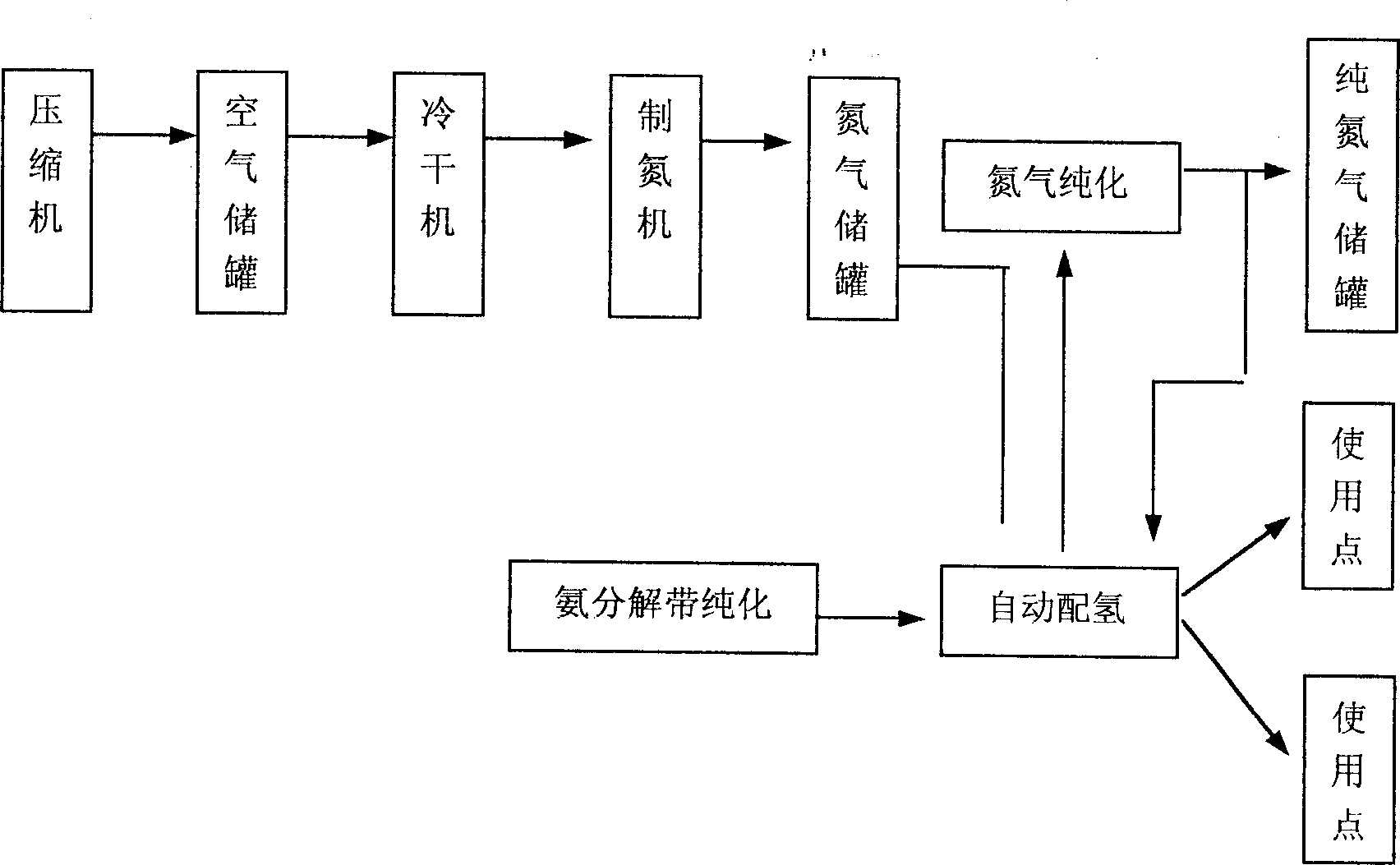

[0009] The semiconductor ceramic capacitor tile semiconducting process method is characterized in that: nitrogen and hydrogen mixed gas decomposed from pure nitrogen and liquid ammonia are used as the reducing and sintering atmosphere of the grain boundary layer semiconductor tile and the semiconducting of the surface layer semiconductor tile Restore the atmosphere. The pure nitrogen is produced by a nitrogen generator.

[0010] The reduction and sintering atmosphere of the grain boundary layer semiconductor tiles contains hydrogen in a proportion of 2% to 20%.

[0011] The semiconducting reduction atmosphere of the surface layer semiconductor tiles contains hydrogen in a proportion of 5% to 30%.

[0012] The present invention is realized by a set of gas supply system, and this gas supply system is divided into following five parts:

[0013] 1. Air compression and purification system:

[0014] The air compression and purification system consists of air compressors, filters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com