Process for preparing disposable full degradation product

A preparation process and fully degradable technology, applied in the field of preparation process of disposable fully degradable products, can solve the problems of poor product strength, cumbersome process, environmental pollution, etc., and achieve the effects of low cost, simple process and elimination of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Production of fully degradable tableware and bowl products. Carry out batching (calculate with weight %) in following proportion:

[0033] 1) Potato starch 40; 2) Light calcium carbonate 6; 3) Edible talcum powder 40; 4) Straw fiber 6; 5) Edible gypsum 2; 6) Methylcellulose 4; 7) Monoglycerin 1; 8) Food grade guar gum1.

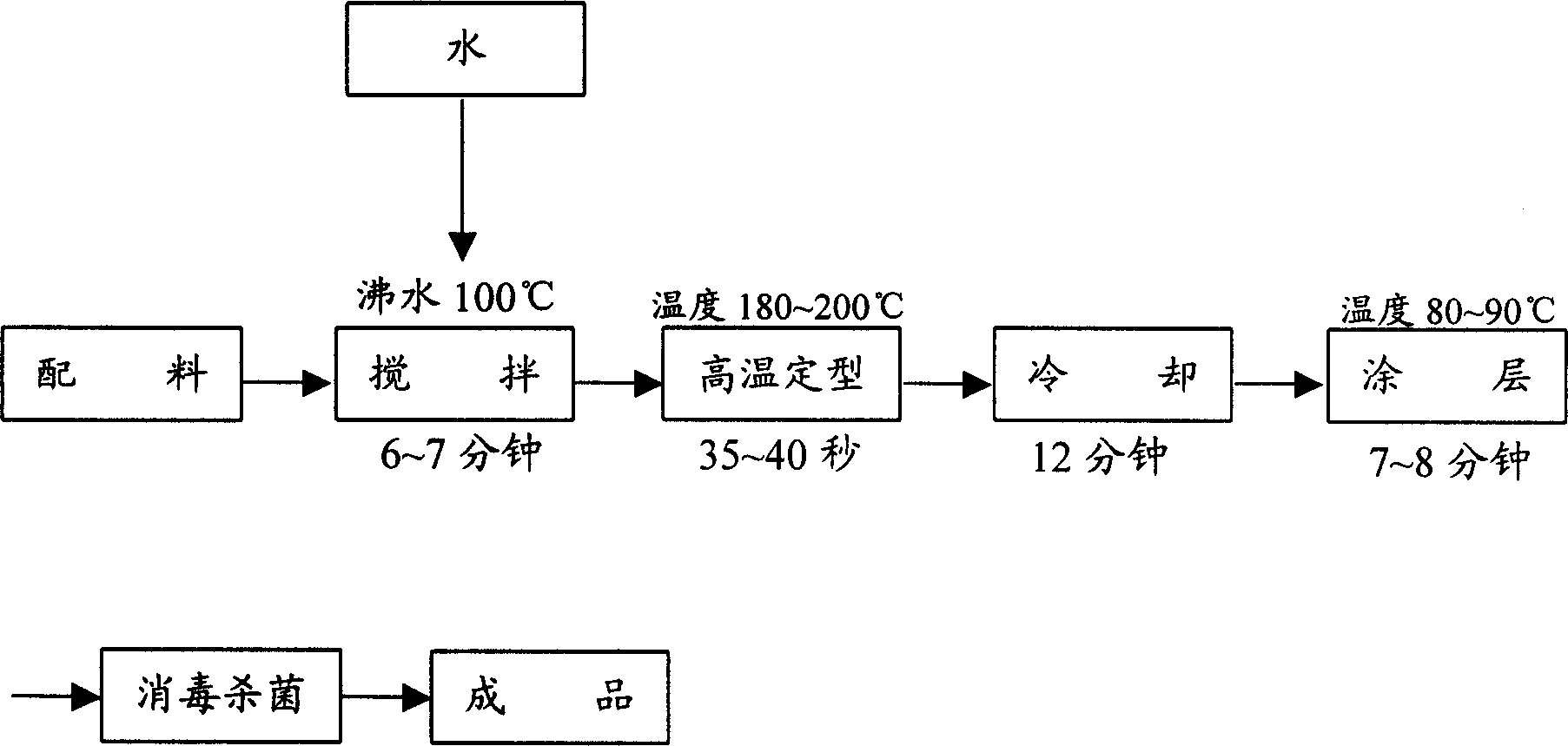

[0034] After the batching is completed, put it into the mixer, and add water in a ratio of 100:35, the water temperature is 100°C, and stir for 6-7 minutes; after stirring evenly, press the bowl embryo, and perform high-temperature heat setting, the setting temperature is 180-200 ℃, the time is 35-40 seconds; followed by cooling for 12 hours to make the product shrink naturally; after that, enter the coating process, the temperature is controlled at 80-90 ℃, the time is 7-8 minutes, the coating material is waterproof, The amount of oil-proof edible spray coating liquid is sprayed according to the dose of 3-5g for each product; finally, it is steriliz...

Embodiment 2

[0036] Production of fully biodegradable tableware cups. Batching is carried out according to the following raw material proportioning (in % by weight). Raw materials and proportioning are:

[0037] 1) sweet potato starch 38; 2) light calcium carbonate 9; 3) edible talcum powder 30; 4) straw fiber 9; 5) edible gypsum 4; 6) methylcellulose 6; 7) monoglycerin 2; 8) edible Grade Guar Gum 2.

[0038] After the batching is completed, put it into the mixer, and add 40% water, stir at the water temperature of 100 ° C, after 6 to 7 minutes, after stirring evenly, it can be pressed into shape, and then, at the temperature of 180 ~ 200 ° C, after 45 Seconds for high-temperature setting, and then after 10 hours of cooling back to the original; then transfer to the coating process, each product is spray-coated with waterproof and oil-proof spray liquid, and each cup is coated with 4 grams ; After ultraviolet sterilization and disinfection, packaging and storage are carried out. The en...

Embodiment 3

[0040] Production of fully biodegradable cutlery trays. In weight percent, carry out batching, raw material proportioning:

[0041] Tapioca starch 47.5; light calcium carbonate 5.0; edible talc powder 33.0; corn orange stalk fiber 6.0;

[0042] Edible gypsum 2.0; methylcellulose 4.0; monoglycerin 1.0; edible guar gum 1.5.

[0043] After batching according to the above formula, put it into the mixer, then add 100:30 clear water, raise the temperature to 100°C, and stir for 6-7 minutes; after stirring evenly, press the disc embryo, and perform high-temperature heat setting, and the setting temperature is controlled at 190°C , the time is 40 seconds; then 12 hours of natural cooling back to the original; after that, transfer to the coating process, the temperature is controlled at 85 ° C, the time is 8 minutes, the coating is edible spray liquid, and the amount is sprayed according to the surface of each plate The amount of 5g controls the feeding speed; then enters the sterili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com