Organic electroluminescence device with improved light-emitting efficiency

An electroluminescent device and organic technology, applied in electroluminescent light sources, electrical components, luminescent materials, etc., can solve the problems of limiting device expansion and limitation, and achieve improved efficiency, high luminous efficiency, and good carrier transport capability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

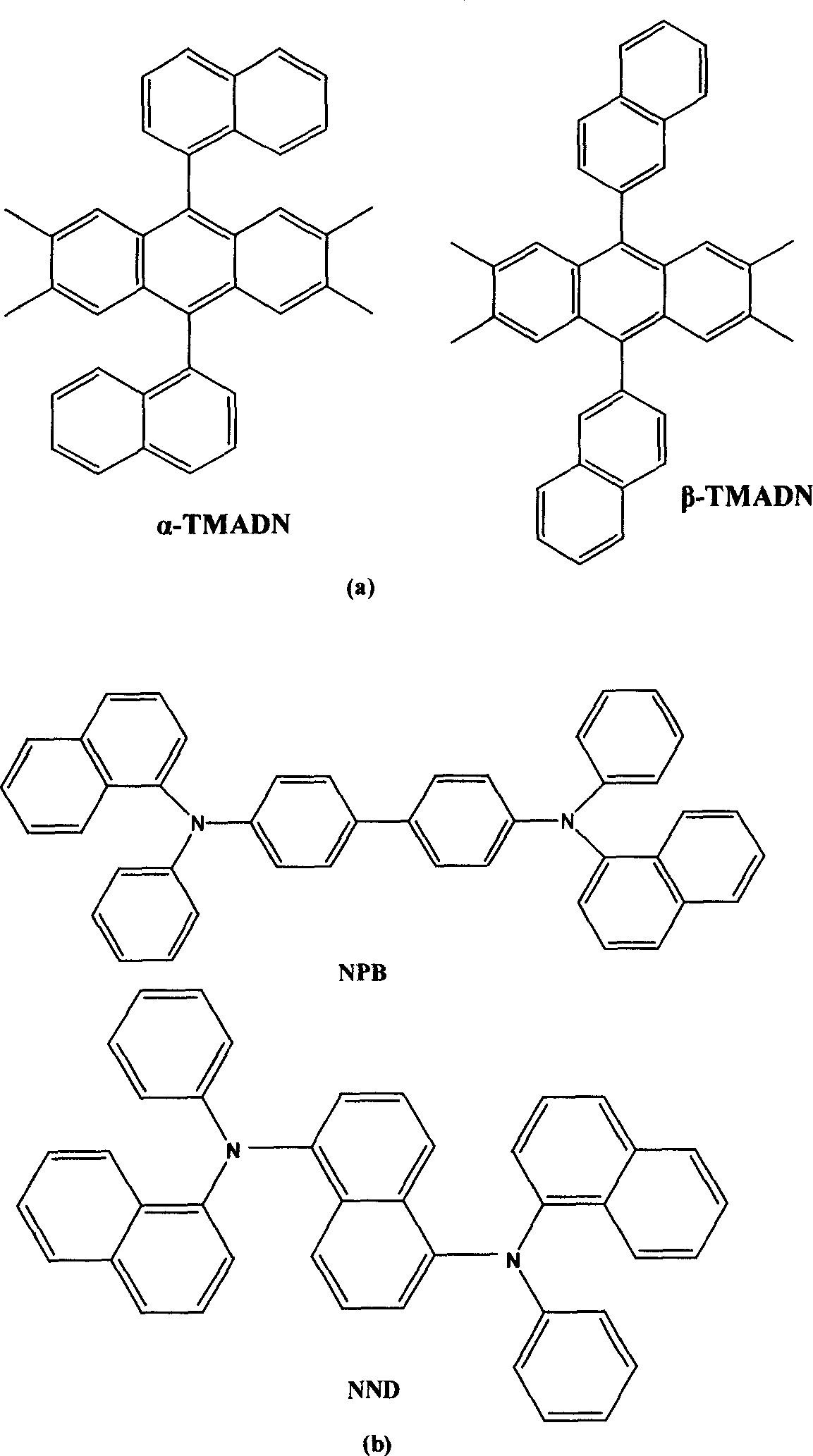

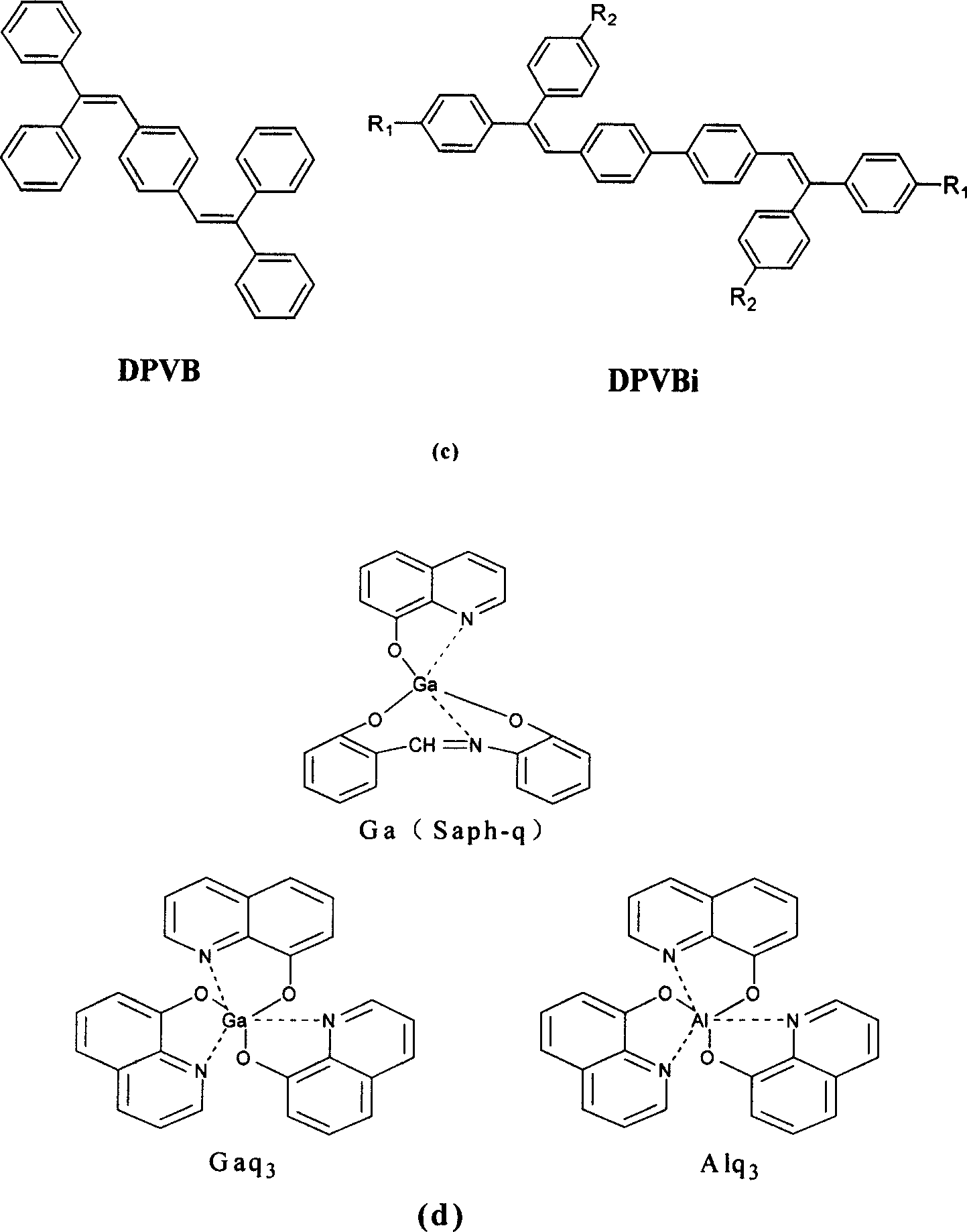

Embodiment 1

[0030] Preparation of device 1: Deposit a layer of indium oxide-tin oxide (ITO) as a transparent anode on a glass substrate, and then prepare a layer of 50 nm thick hole transport material by vacuum evaporation: N, N'- Diphenyl-N,N′-bis(1-naphthyl)-1,1′-biphenyl-4,4′-diamine (NPB) was then continued on this hole-transporting layer by vacuum evaporation of dual-source A layer of 15 nanometer thick material in the present invention, 2,3,6,7-tetramethyl-9,10-bis(1-naphthyl)anthracene (compound α-TMADN) and 2,3, 6,7-tetramethyl-9,10-bis(2-naphthyl)anthracene (compound β-TMADN), the concentration ratio is 9:1 (α-TMADN: β-TMADN), as the light-emitting layer; again here On the light-emitting layer, a layer of 40 nm-thick hole-transporting material and hole-blocking material 4,7-diphenyl-1,10-phenanthroline (BPhen) is continuously deposited by vacuum evaporation, and finally vacuum-evaporated A layer of Mg:Ag (1:10) alloy is used as the cathode of the device, about 200 nm. Add the p...

Embodiment 2

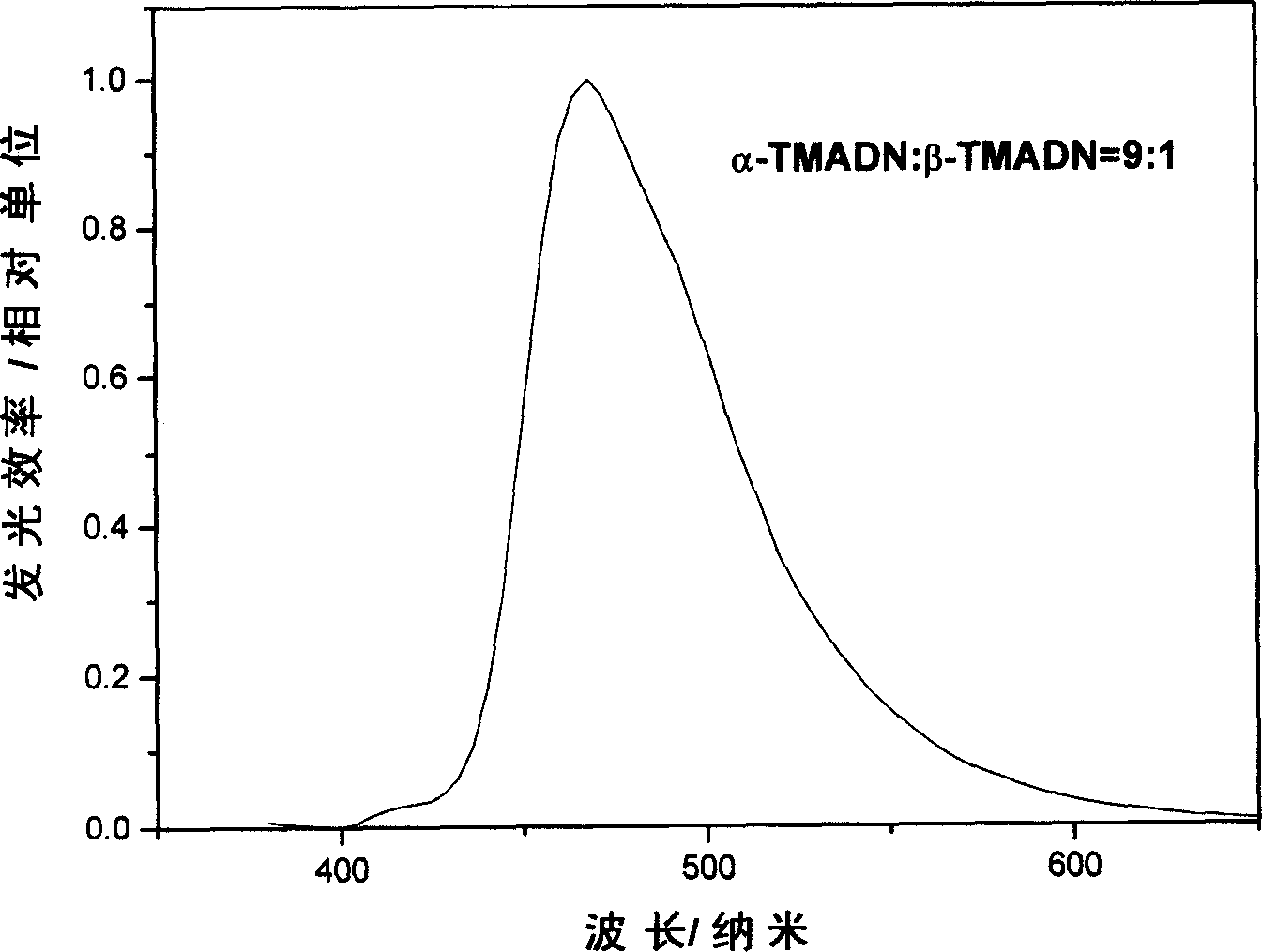

[0032]A group of devices were prepared according to the preparation method and steps of Example 1, and the light-emitting layer materials were also 2,3,6,7-tetramethyl-9,10-di(1-naphthyl)anthracene (compound α-TMADN) and 2,3,6,7-Tetramethyl-9,10-bis(2-naphthyl)anthracene (compound β-TMADN), adjust the concentration ratio of α-TMADN and β-TMADN, the device can achieve different luminous efficiencies , see attached Figure 5 .

Embodiment 3

[0034] Preparation of device 2: Deposit a layer of indium oxide-tin oxide (ITO) as a transparent anode on a glass substrate, and then prepare a layer of 50 nm thick hole transport material by vacuum evaporation: N, N'- Diphenyl-N,N′-bis(1-naphthyl)-1,1′-biphenyl-4,4′-diamine (NPB) was then continued on this hole-transporting layer by vacuum evaporation of dual-source A layer of material N, N'-diphenyl-N, N'-bis(1-naphthyl)-1,1'-biphenyl-4,4'-di Amine (NPB) and 1,5-bis[N-(naphthyl)-N-phenyl]naphthalene diamine (NND) in a concentration ratio of 7:1 (NPB:NND) as the light-emitting layer; On the layer, a layer of 40 nm-thick hole transport material and hole blocking material 4,7-diphenyl-1,10-phenanthroline (BPhen) was deposited by vacuum evaporation, and finally a layer of vacuum evaporation was deposited. A layer of Mg:Ag (1:10) alloy acts as the cathode of the device, about 200 nm. Add the positive electrode of direct current to the ITO layer, and add the negative electrode t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com