Polymer-based waveguide device and method for fabricating the same

A manufacturing method and polymer technology, applied in the direction of optical waveguide light guide, laser components, optics, etc., can solve the problems of unsuitable waveguide amplifiers, long manufacturing cycle, increased optical loss, etc., to achieve increased concentration of rare earth metal ions and low cost , high gain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

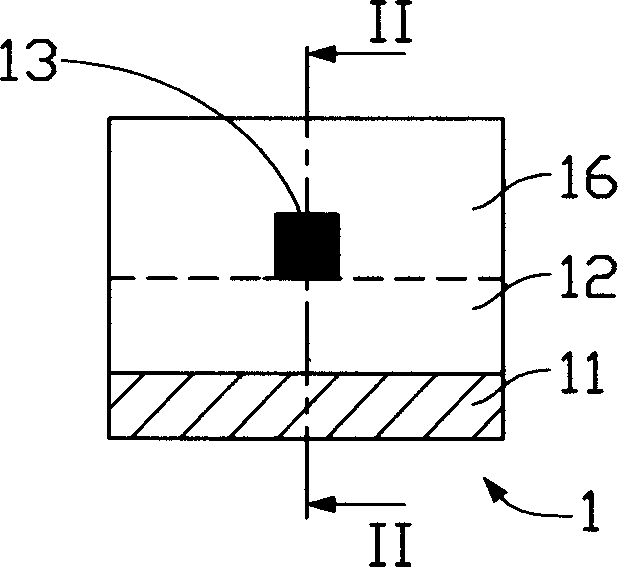

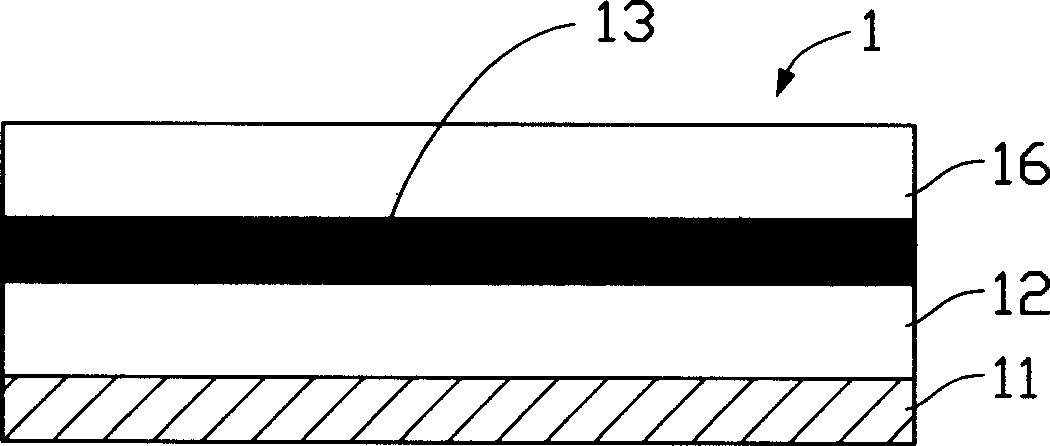

[0011] Please refer to figure 1 , the polymer-based waveguide device 1 of the present invention can be used as an optical amplifier or a laser waveguide, which includes a substrate 11 , a polymer inner cladding layer 12 , a polymer outer cladding layer 16 and a channel waveguide 13 . The polymer inner cladding layer 12 covers the substrate 11 , and the channel waveguide 13 is disposed on the polymer inner cladding layer 12 and wrapped in the polymer outer cladding layer 16 . Please also refer to figure 2 , the channel waveguide 13 is substantially parallel to the substrate 11 .

[0012] The manufacture of the polymer-based waveguide device 1 can be carried out in the following four steps:

[0013] (1) Prepare the substrate 11. The material of the substrate 11 can be single crystal silicon, polycrystalline silicon, lithium niobate single crystal, quartz, optical glass or optical resin, and be formed by the existing stretching or casting process;

[0014] (2) coating on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com