Method for synthesis of diisopropenyl by propylene dimerization

A technology for the dimerization of dimethylbutene and propylene, which is applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of expensive co-catalysts for catalyst synthesis raw materials, complex catalyst preparation, and harsh reaction conditions. Achieve the effect of eliminating solvent separation and recovery, simple composition and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

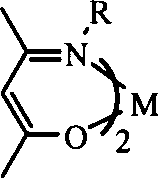

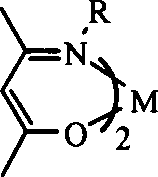

Image

Examples

Embodiment 1

[0028] Example 1: In a 250mL autoclave, under a propylene atmosphere, add 0.008mmol of complex C and 0.24mmol of PCy prepared in advance in a Schlenk bottle 3 Ligand (P / Ni molar ratio is 30) and 18mL chlorobenzene solution, after constant temperature to 20°C, add 1.6mmol 10%Et 3 al 2 Cl 3 Toluene solution (Al / Ni molar ratio is 200), stirred for 10min, then adjusted the gauge pressure of propylene to 0.4MPa, and kept the pressure steady for 60min; the material was extruded, hydrolyzed, and the composition and content of the product were analyzed by GC. The results are shown in Table 1.

Embodiment 2

[0029] Embodiment 2: 0.032mmol PCy 3 Ligand (P / Ni molar ratio is 4), other experimental methods and conditions are the same as in Example 1. The results are shown in Table 1.

Embodiment 3

[0030] Example 3: Et 3 al 2 Cl 3 The toluene solution is the cocatalyst, and the Al / Ni mol ratio is 100, and other experimental methods and conditions are the same as in Example 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com