Fibre-optical probe with excellent vibration characteristic and producing method thereof

A technology of optical fiber probe and vibration characteristics, which is applied in the field of scanning optical microscopy imaging, can solve problems such as failure to work, system failure to work well, and difficulty in forming a fundamental frequency vibration frequency curve, etc., to achieve increased costs, no transmission efficiency, The effect of excellent vibration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

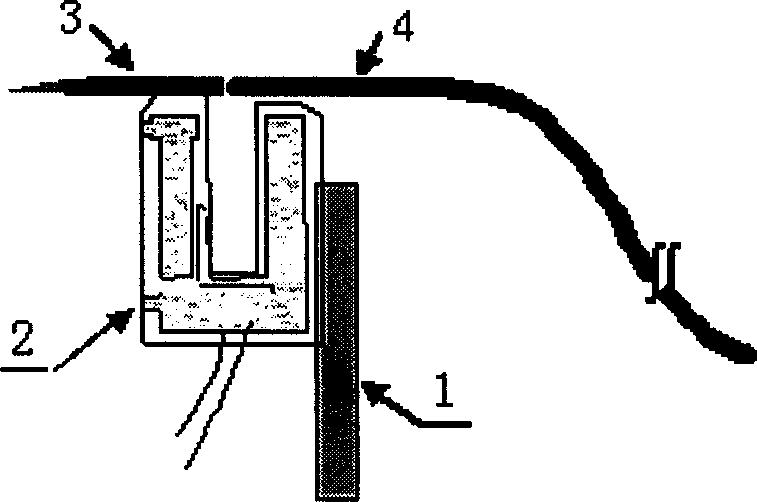

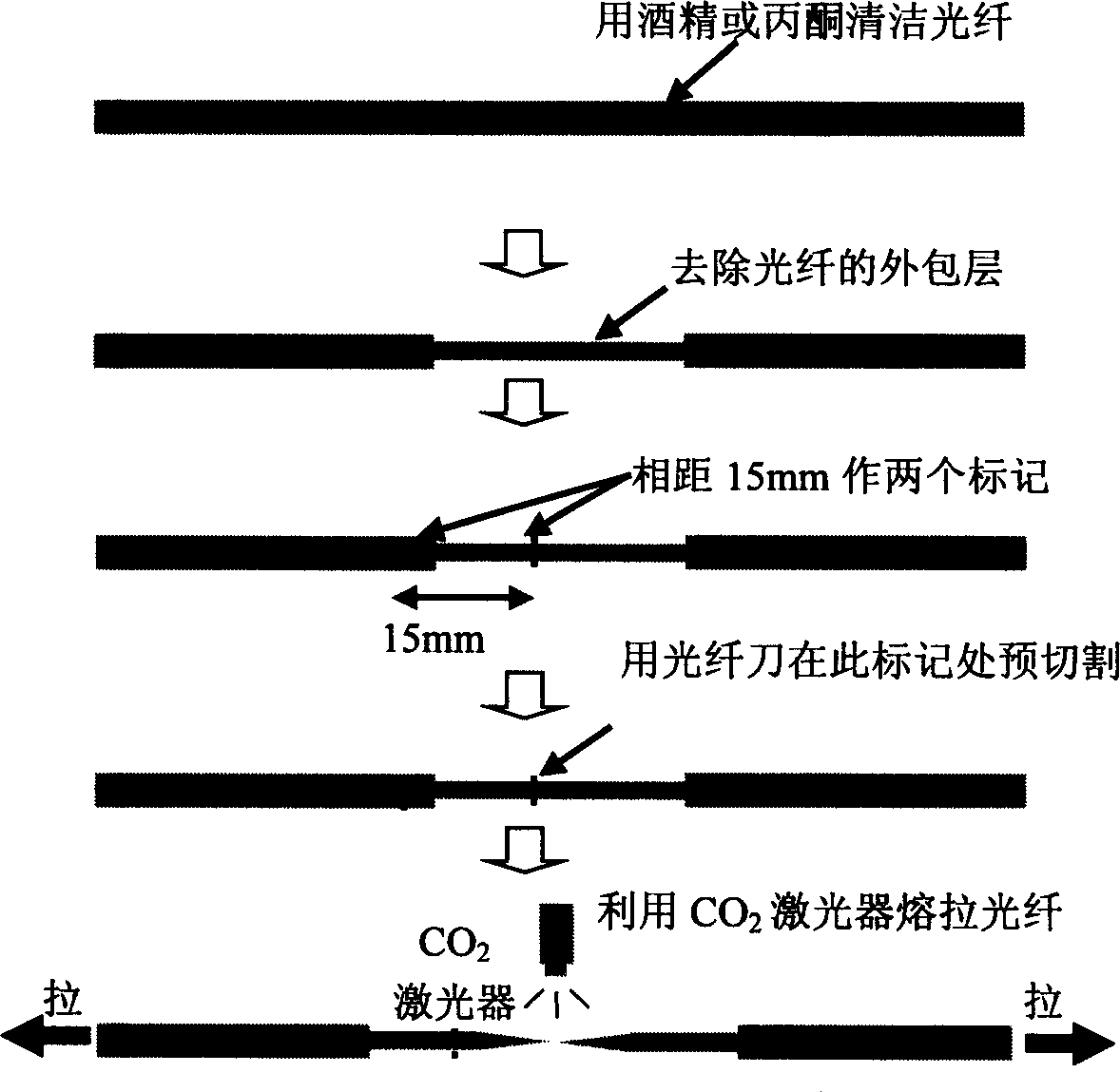

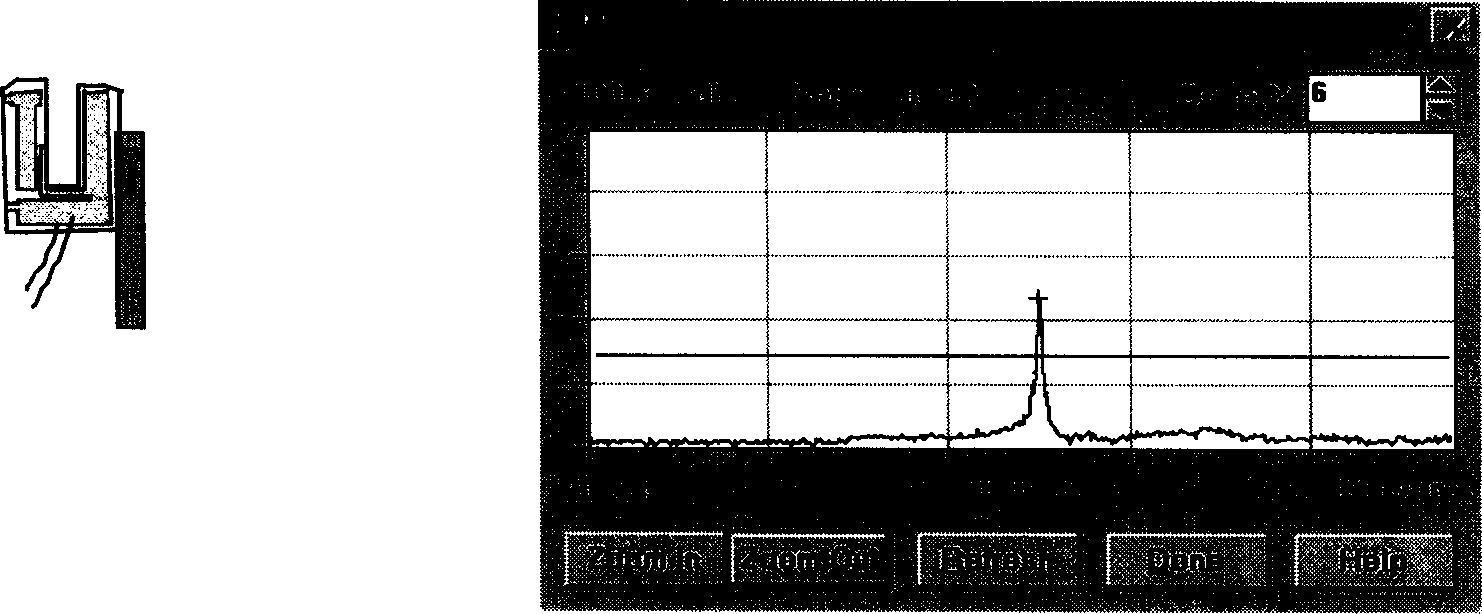

[0017] 1. Pre-production of fiber optic probes

[0018] The following steps are used in the pre-production of fiber optic probes: ①melting or chemical etching or corrosion after melting to form a micro-probe; ②coating a layer of metal film on the micro-probe to form a nanometer-sized optical aperture at the tip of the probe . What the present invention specifically adopts is the method of laser heating melting drawing, and the optical fiber melting drawing machine used is the model P-2000 optical fiber melting drawing machine produced by Sutter Instrument Company.

[0019] First, cut a section of single-mode optical fiber with a length of about 20cm and a diameter of 0.125mm, and use a mechanical fiber peeler to strip the outer cladding of the optical fiber for about 30mm in the middle; use an oil-based pen at a distance of about 3mm from the starting point of the end where the cladding is removed. The first mark (this mark is located on the outer cladding of the fiber), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com