Two-step method of hydrogen production by biologically photolyzing water using ocean green algae

A technology of marine green algae and bio-light, applied in biochemical equipment and methods, microbes, treatment of microbes with electricity/wave energy, etc., can solve the problems of difficult reuse of microalgae biomass, long process route, complicated operation, etc. To achieve the effect of promoting photosynthetic dehydrogenation, reasonable hydrogen production route and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

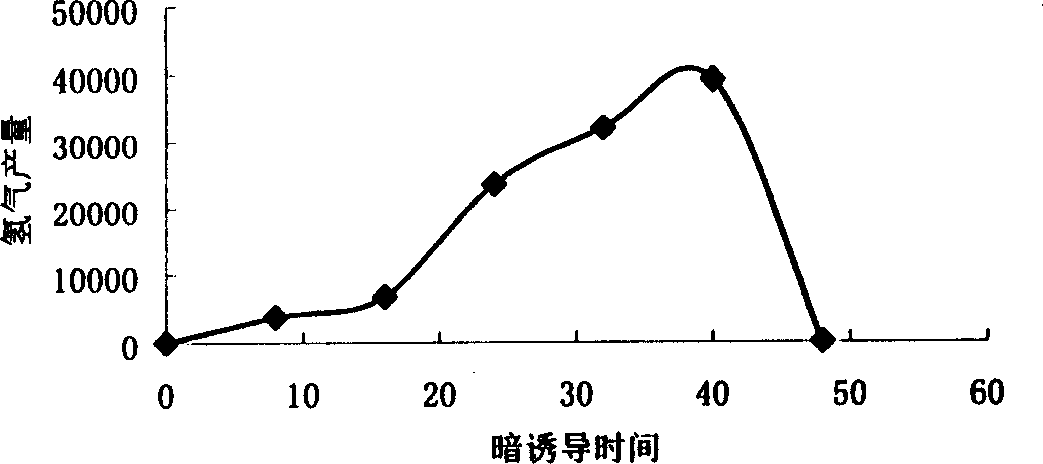

[0022] Embodiment 1 (optimization of the dark induction time utilizing sulfur-free seawater medium to produce hydrogen)

[0023] Collect the Phytophthora cells in the late logarithmic growth period, centrifuge and wash 3 times with fresh sulfur-free seawater medium, and then adjust to 1.0~1.2×10 6 The cell concentration in cells / mL; take a plasma bottle with a volume of 300mL, which contains 295mL of algae liquid, seal the mouth of the bottle with a rubber stopper, connect the needle of the infusion set tightly with the upper space of the plasma bottle, and fill it with nitrogen for 5 minutes; at 25°C, place Store in the dark for different periods of time, use the dark respiration of algae cells to consume the oxygen sealed in the bottle, make it anaerobic, and induce the activity of hydrogen-producing enzymes. -2 the s -1 Hydrogen desorption under light and 150rpm rotary shaking. The infusion set hose is placed in an inverted graduated test tube, and the gas volume is colle...

Embodiment 2

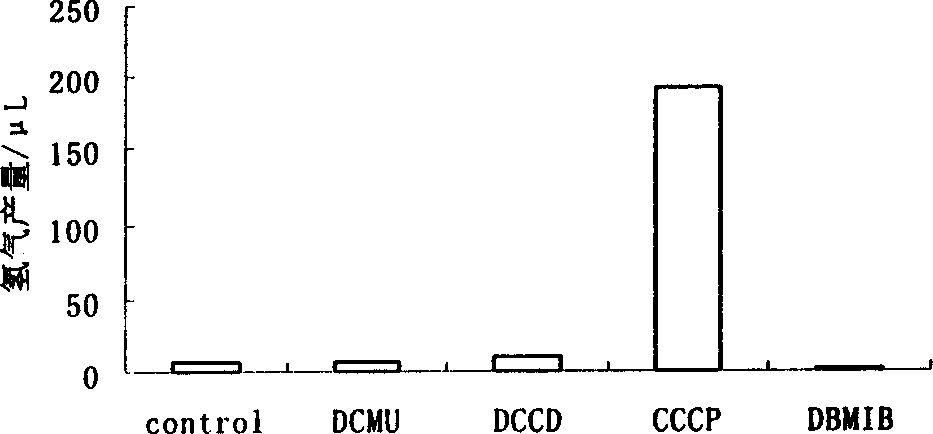

[0025] Embodiment 2 (the influence of uncoupling agent on hydrogen production)

[0026] Using 295mL of flat algae cell suspension as a blank experiment, the photosynthetic hydrogen production lasted for 3 hours, and the yield was 6.3μL. After dark anaerobic induction of algae liquid in natural seawater, the regulator was added 5 minutes before the start of light, and the results are shown in figure 2 (The influence of DCMU, DCCD, CCCP, DBMIB on hydrogen production); DCMU of 50 μ M makes the flat algal cells of the same concentration and quantity produce hydrogen 6.7 μ L, which is 6% higher than the hydrogen production of blank experiment; DCCD of 2 μ M makes its hydrogen production be 9.9 μL, 57% more hydrogen production than the blank test; 10 μM CCCP made the hydrogen production process last for 6 hours, and the hydrogen production was 191 μL, which was 30 times that of the blank test; 5 μM DBMIB made the hydrogen production 1.7 μL, which was blank 27% of trials. Uncouple...

Embodiment 3

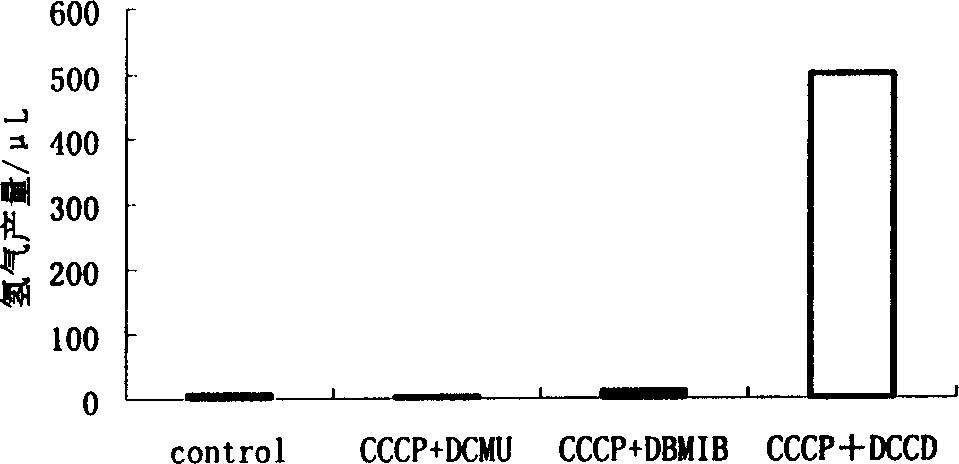

[0027] Embodiment 3 (the influence of uncoupling agent and proton pump inhibitor acting together on hydrogen production)

[0028] After dark anaerobic induction of algae liquid in natural seawater, the regulator was added 5 minutes before the light began, the results are shown in Table 1 and image 3 (Effects of DCMU, DBMIB, DCCD on the hydrogen production of flat algae added with CCCP). Compared with the hydrogen production by photolysis of water by microalgae using only natural seawater, both the uncoupler alone and the combined action of the proton pump inhibitor prolong the hydrogen production time from 3 hours to 6 hours.

[0029] In the blank test, the hydrogen production was 6.3 μL. Under the joint action of 10 μM CCCP and 50 μM DCMU, the same amount of flat algal cells in the same state produced 2.4 μL of hydrogen, which was 0.38 of the blank test; 10 μM CCCP and 5 μM DBMIB made it The hydrogen production was 10.6 μL, which was 1.68 times that of the blank test; 10 μM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com