Process for preparing nitridation carbon / carbon nanotubes and nano diodes and use thereof

A nano-diode and carbon nano-tube technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve problems such as complex preparation methods, and achieve the effects of simple process, stable performance, and excellent rectification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present invention prepares the method for carbon nitride / carbon nanotube nano diode:

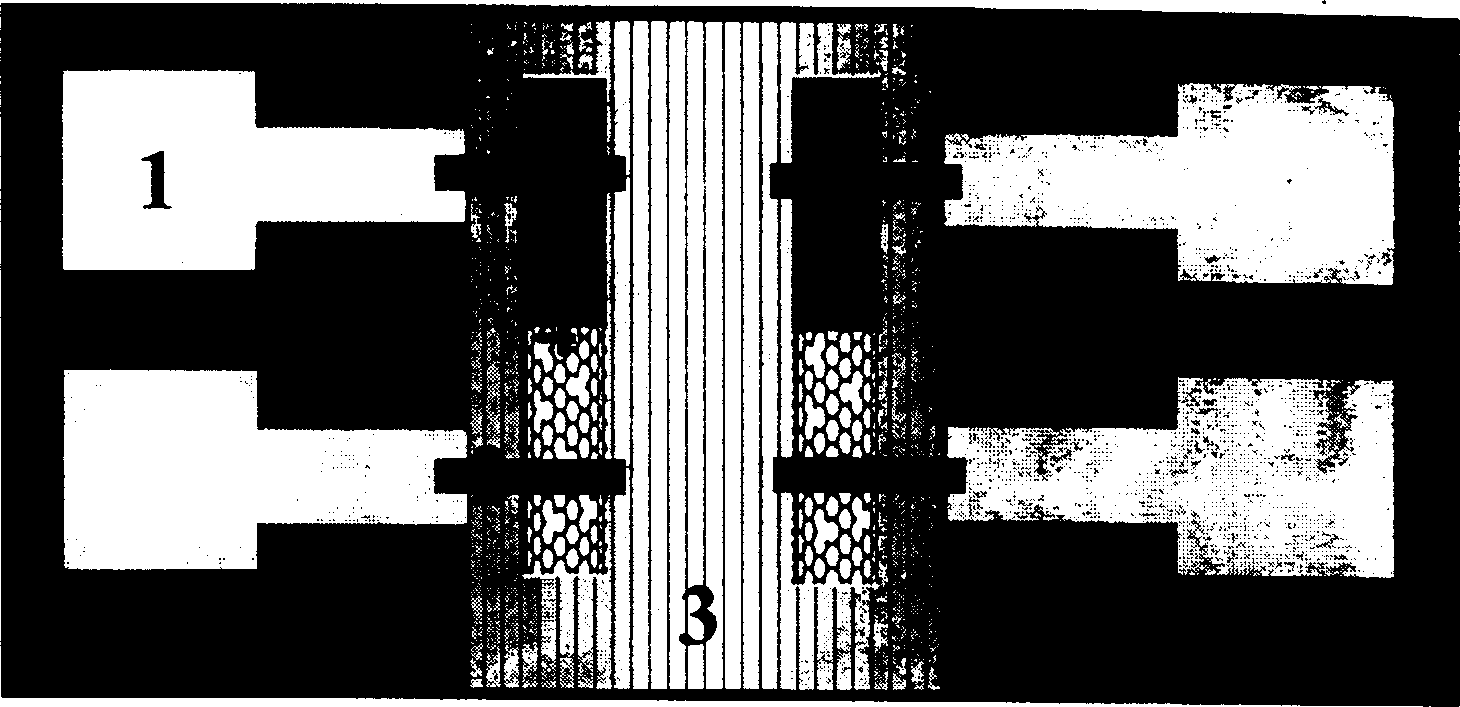

[0041] In the first step, thermally oxidized silicon dioxide (SiO 2 , 500 nanometers) 3 surface with a photolithographic technique to prepare a pair of Ti / Au electrode arrays, the electrode width is 1 micron, and the distance between the electrodes is 5-10 microns.

[0042] In the second step, the prepared carbon nitride / carbon nanotubes are then dispersed in carbon tetrachloride and dichlorobenzene solution, (the preparation method of carbon nitride / carbon nanotubes is referring to: Liu Yunqi, Hu Ping'an, Xiao Kai, Wang Xianbao , Fu Lei, Zhu Daoben, application number: 02160815.6), drop a suspension containing carbon tubes on silicon dioxide (SiO 2 )3 on the base.

[0043]The 3rd step, after the solvent volatilizes completely, put into the vacuum chamber of IDS P2X focused ion beam (FIB) system, observe the carbon tube on the substrate 3 (diameter is 50 nanometers, length 4 mi...

Embodiment 2

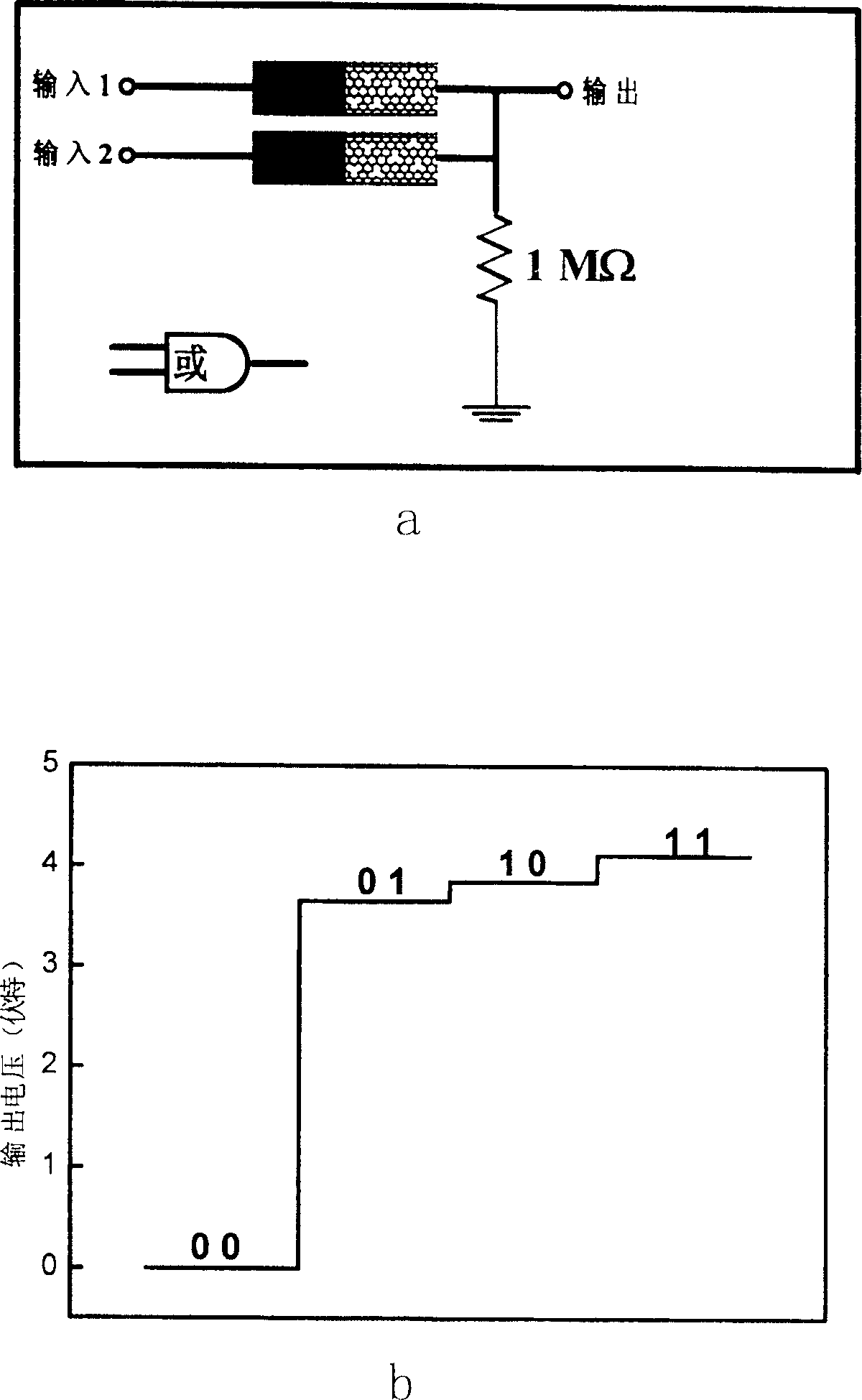

[0046] The present invention consists of a carbon nitride / carbon nanotube nanodiode to form a preparation method of a logic gate circuit:

[0047] In the first step, prepare two carbon nitride / carbon nanotube diodes according to the preparation method of Example 1;

[0048] In the second step, the prepared two carbon nitride / carbon nanotube diodes were connected with a resistance of 1 megohm according to image 3 a and Figure 4 The circuit diagram shown in a, respectively connected into a diode logic "or" (see image 3 a) and "and" (see Figure 4 a) Gate circuit, the resistance value of grounding and positive 5V resistance can be selected between 500K and 1.5 megohm, and the preferred value is 1 megohm.

[0049] Its logic output curve is as image 3 b and Figure 4 As shown in b. When one of the two input terminals is high level, the output is high level, which is an "or" gate circuit; and when both input terminals are high level, the output is high level, which is "and...

Embodiment 3

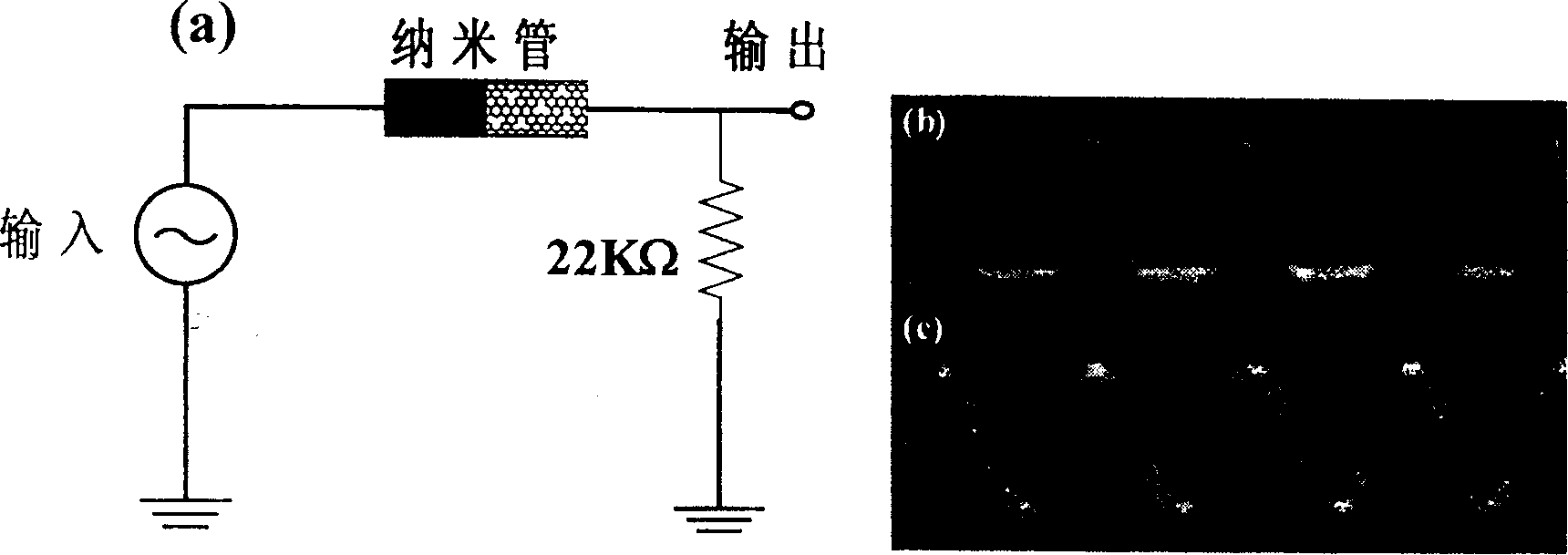

[0051] Application of the present invention in transistor radio:

[0052] Replace the silicon diode in the Sanyo RP1270 transistor radio with the carbonized nitrogen / carbon nanotube diode prepared according to embodiment 1 (see Figure 5 ), the radio can still clearly listen to different radio programs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com