Method for extracting rice protein from rice

A rice protein and rice technology, which is applied in the processing of plant protein, etc., can solve the problems of reduced nutritional value, denaturation of rice protein, cumbersome process, etc., and achieve the effects of avoiding protein loss, low degree of protein denaturation, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

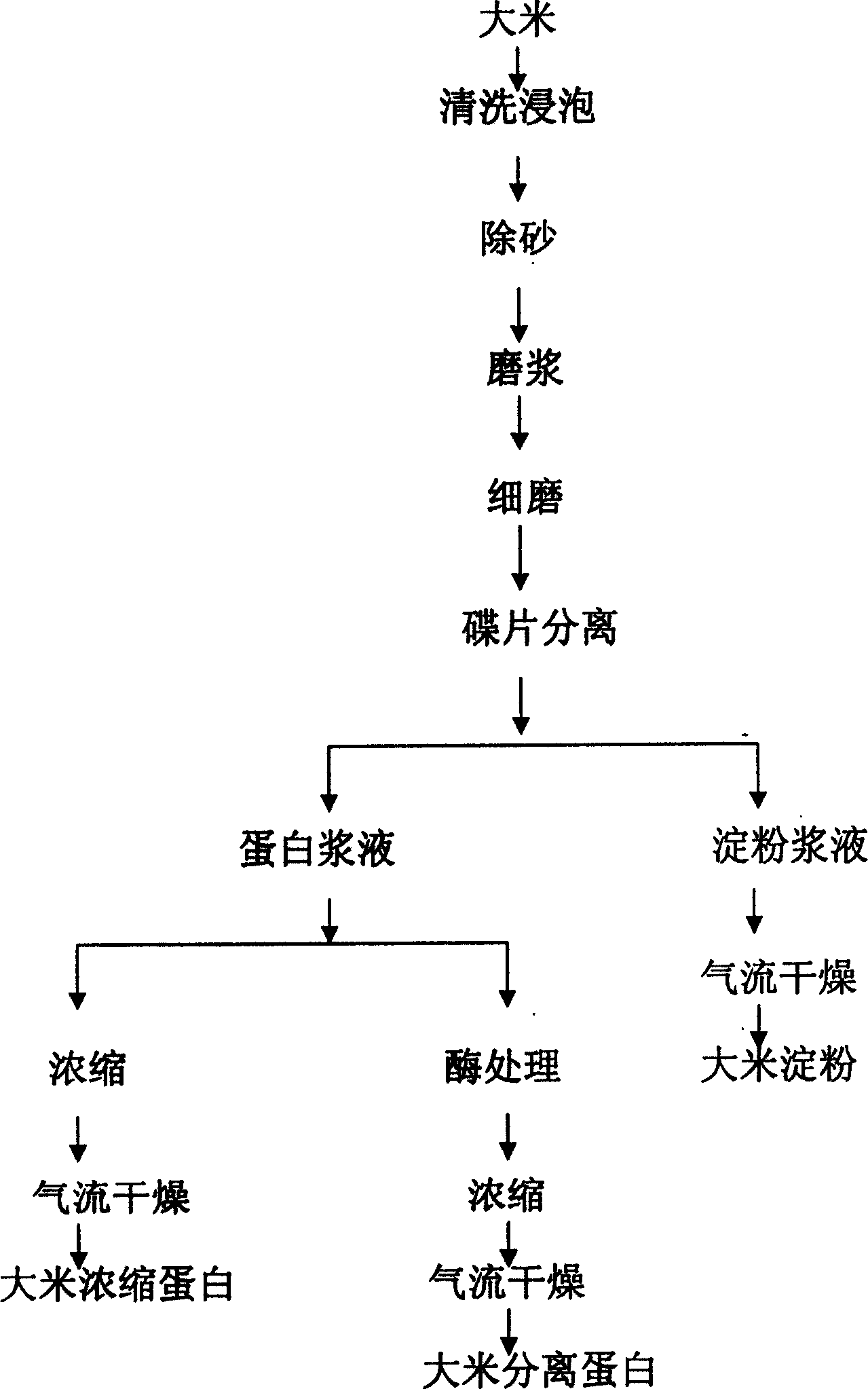

Method used

Image

Examples

Embodiment 1

[0052] Take by weighing 200kg of early indica rice, put into the cleaning tank, soak for 2 hours after cleaning; send into the cyclone desander, the cone angle of the cyclone desander is 45°, the pressure is 0.1Mpa, the desander is 25mm, two-stage desandering; Put into a refiner to refine to a fineness of more than 80 meshes, and keep the slurry concentration at about 10%; input the slurry into a colloid mill for fine grinding twice, with a pore size of 0.1mm, and take 10 minutes; input the slurry into a disc separator for three-stage separation (separation The starch slurry at the bottom outlet outlet is concentrated and then sent to the ebullating bed for drying to obtain rice starch, the following examples are the same); in the three-stage separation, the protein slurry at the top overflow port is collected and combined, then press-filtered, and the filter residue is sent to the ebullating bed for drying , control the temperature of the material below 80°C to obtain concentr...

Embodiment 2

[0054] Take 200kg of early indica rice, put it into a cleaning tank, soak for 2.5 hours after cleaning; send it into the cyclone desander, the cone angle of the cyclone desander is 45 °, the pressure is 0.1Mpa, the desander is 25mm, two-stage desandering; Put into a refiner to refine to a fineness of more than 80 mesh, and maintain a slurry concentration of about 10%; input the slurry into a colloid mill for fine grinding twice, with a pore size of 0.08mm, and take 12 minutes; input the slurry into a disc separator for three-stage separation; a part In the three-stage separation, the protein slurry at the top overflow port is collected and combined, and then press-filtered; the filter residue is sent to the ebullating bed for drying, and the temperature of the material is controlled below 80°C to obtain concentrated rice protein. Another part of the tertiary separation, the top overflow port protein slurry is collected and combined, enters the enzymolysis tank, and the followin...

Embodiment 3

[0056] Take by weighing 200kg of early indica rice, put into cleaning tank, soak for 3 hours after cleaning; send into cyclone desander, the cone angle of the cyclone desander is 45°, the pressure is 0.1Mpa, the desander is 25mm, two-stage desandering; Put into a refiner to refine to more than 80 mesh, and keep the slurry concentration at about 10%; input the slurry into the colloid mill for fine grinding twice, with a pore size of 0.05mm, and take 15 minutes; input the slurry into the disc separator for tertiary separation; during the tertiary separation After the protein slurry at the top overflow port is collected and combined, it enters the enzymatic hydrolysis tank, and the following enzyme solutions are added in turn for reaction: α-amylase: 30g enzyme amount, reaction time 65°C, pH=6.0, reaction time 1 hour; cellulose Enzyme: 30g of enzyme added; reaction time 45°C, PH = 4.5, reaction time 3 hours; lipase: 50g enzyme amount, reaction time 50°C, PH = 7.0, reaction for 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com