Chemical plating nickel conductive film on polymer thin film surface and method for preparing the same

A polymer film, chemical nickel plating technology, applied in the field of chemical plating, can solve problems such as difficulty in plating nickel, achieve the effects of lightweight shielding materials, reduce electromagnetic pollution, and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

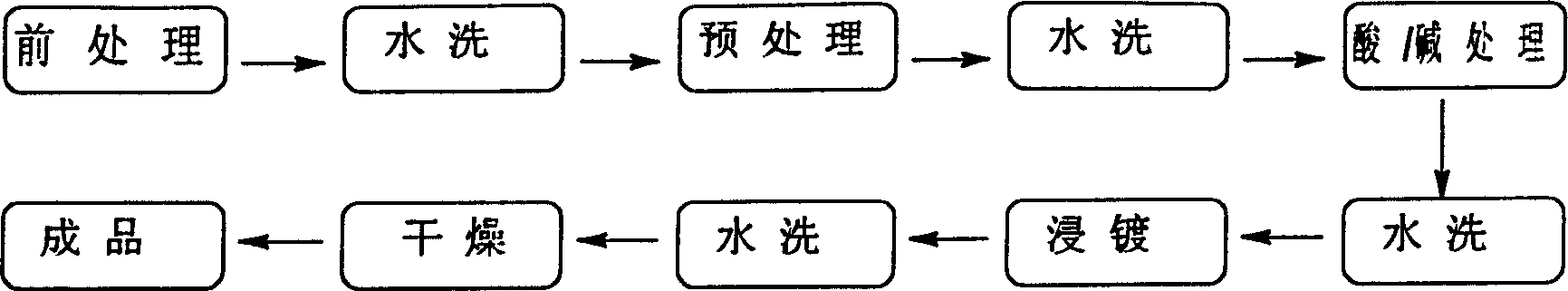

[0028] Such as figure 1 The preparation method of the electroless nickel-plated conductive film on the surface of a polymer film shown, adopts 2 * 5cm 2 , a polyethylene terephthalate (PET) film with a thickness of 120m as the substrate, immersed in a 30g / L NaOH solution at 60°C for 30min, washed with water, immersed in a solution containing 10g / L stannous chloride, 0.5g / L Palladium chloride, in 20g / L 37% hydrochloric acid solution for 1min, washed with water, immersed in 20g / L hydrochloric acid solution for 1min, washed with water to complete pretreatment and pretreatment. Then immerse in the 80°C plating solution for 1min, the formulation of the plating solution is nickel chloride 25g / L, sodium hypophosphite 15g / L, sodium citrate 120g / L, ammonium chloride 40g / L, pH value 9. A nickel-plated PET conductive film is obtained, the thickness of the coating is about 1 μm, and the coating is dense under microscope observation.

Embodiment 2

[0030] Such as figure 1 The preparation method of the electroless nickel-plated conductive film on the surface of a polymer film shown, adopts 2 * 5cm 2 , a polyethylene terephthalate (PET) film with a thickness of 120 μm is the substrate, and the pretreatment and pretreatment are completed as in Example 1. Then immerse in a 45°C plating solution for 10 minutes. The difference is that the formulation of the plating solution is nickel sulfate 45g / L, sodium hypophosphite 30g / L, sodium pyrophosphate 50g / L, triethanolamine 15g / L, and pH 9.5. A nickel-plated PET conductive film was obtained, the thickness of the coating was about 5 μm, and the coating was dense under microscope observation.

Embodiment 3

[0032] Such as figure 1 The preparation method of the electroless nickel-plated conductive film on the surface of a polymer film shown, adopts 2 * 5cm 2 , a polyethylene terephthalate (PET) film with a thickness of 120 μm is the substrate, and the pretreatment and pretreatment are completed as in Example 1. Then immerse in the plating solution at 85°C for 1.5 minutes. The difference is that the formulation of the plating solution is nickel chloride 25g / L, sodium hypophosphite 15g / L, sodium glycolate 60g / L, lead nitrate 0.001g / L, twelve Sodium alkyl sulfate 0.02g / L, pH 5. A nickel-plated PET conductive film was obtained, the thickness of the coating was about 2 μm, and the coating was dense under microscope observation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com