Anode structure of electrolysis type ozone generator and its preparation method

An ozone generator and anode structure technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of reducing the effective contact area of β-lead dioxide particles, reducing the reaction efficiency, and reducing the ozone production rate. The stability of product quality and the effects of industrial scale production, improved working life, and improved ozone yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

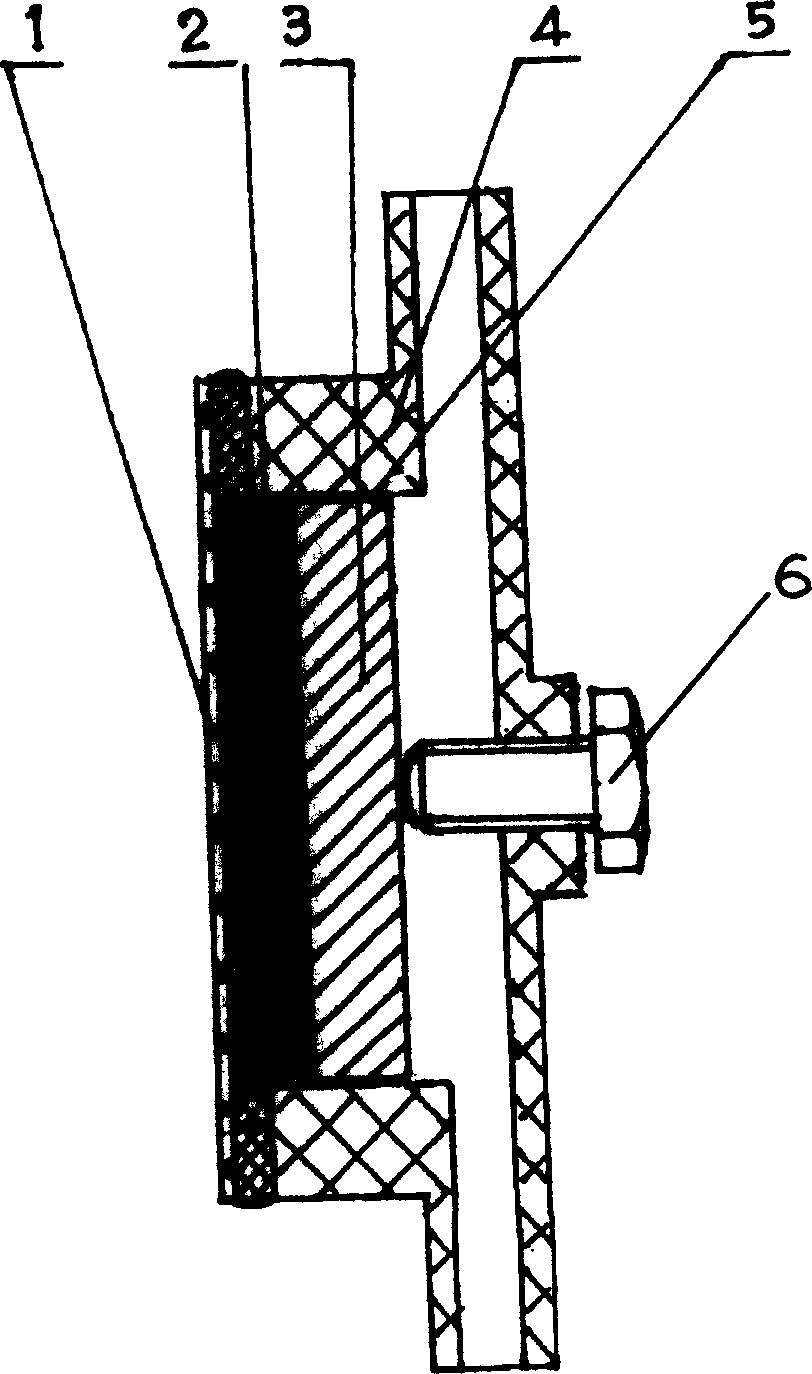

[0022] See figure 1 , the specific embodiment of the present invention is as follows: the lead dioxide particle 2 that particle diameter is 0.05~0.15mm is laid on the anode frame body 4 that is made of perfluorosulfonamide cation exchange membrane (DuPont Nafion117) 1 and polyfluorotetraethylene In the formed space, the laying thickness of the particles is 3mm, and then the cover is made of industrial pure titanium, and the dense impermeable and gas-proof industrial pure metal titanium anode plate 3 with a thickness of 3mm; Form a surface corrosion-resistant conductive layer made of conductive oxides of platinum, tin, and antimony according to conventional methods. After covering the anode plate 3, make the gap 5 between the periphery of the anode plate 3 and the adjacent inner surface of the anode frame 4 0.03mm, and finally use the connecting bolts 6 to connect the above parts into one, so as to assemble the anode structure of the electrolytic ozone generator.

[0023] When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com