Ag/TiO2 composite film with adjustable contact angle and preparation method thereof

A composite film and contact angle technology, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem that the sol is easy to become loose, which is not conducive to the preparation of a large-area uniform film, and the film and the substrate are not well bonded And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

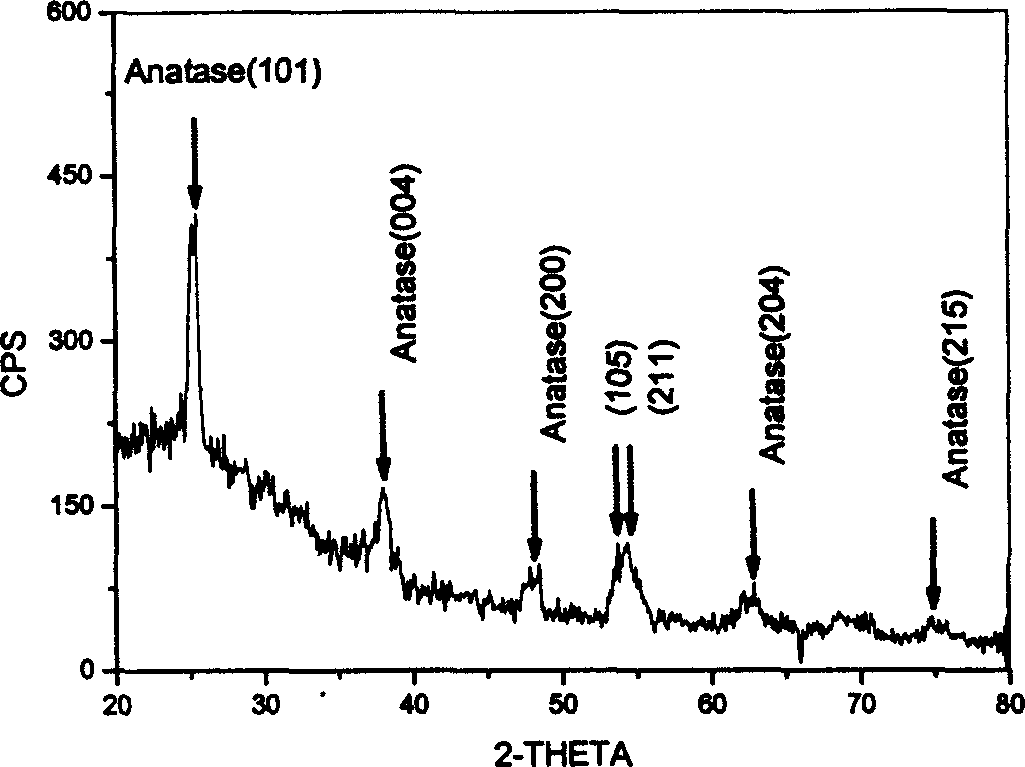

[0025] 1) Take glass sheet as the carrier, after cleaning, put it into the vacuum coating equipment with pure metal titanium target, the background vacuum is 3.0×10 -3 Pa;

[0026] 2) Using intermediate frequency reactive magnetron sputtering technology:

[0027] The frequency of the intermediate frequency AC arc suppression power supply is 25Hz, the working voltage is 300V, and the current density is 2mA / cm 2 , the working gas is 99.99% high-purity argon, and its pressure is 2.0Pa; the reaction gas is high-purity oxygen, and the partial pressure is controlled by a mass flow controller to be 0.2Pa; the carrier temperature during film deposition is 400 ° C; the sputtering time is 60 minutes. After sputtering, a photohydrophilic titanium dioxide film was obtained.

[0028] 3) Medium frequency magnetron sputtering technology to deposit Ag particles

[0029] The frequency of the intermediate frequency AC arc suppression power supply is 25Hz, the working voltage is 300V, and th...

Embodiment 2

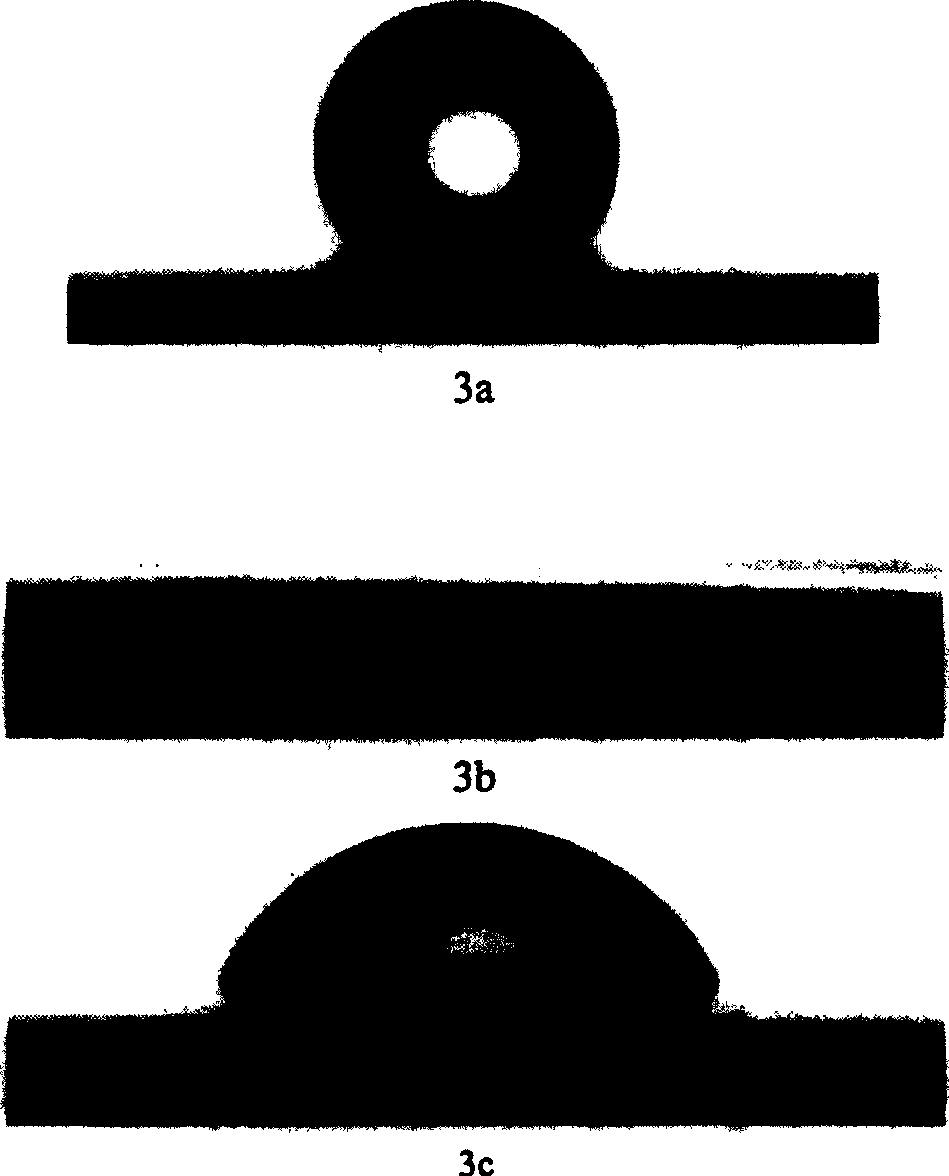

[0036] Ag / TiO obtained under the above conditions 2 In the composite film, the titanium dioxide film is an anatase phase, and the silver particles are about 5nm. The hydrophilic experiment shows that Ag / TiO 2 The composite film showed a strong hydrophobic effect when it was not irradiated, and its contact angle was about 110 degrees. After ultraviolet radiation, the contact angle drops below 20 degrees within 30 minutes, and drops below 5 degrees after 2 hours. After stopping the irradiation for 72 hours, the contact angle returned to about 100.

Embodiment 3

[0038] Ag / TiO obtained under the above conditions 2 In the composite film, the titanium dioxide film is composed of anatase phase and amorphous phase, and the silver particles are about 8nm. The hydrophilic experiment shows that Ag / TiO 2 The composite film showed a strong hydrophobic effect when it was not irradiated, and its contact angle was about 100 degrees. After ultraviolet radiation, the contact angle drops below 10 degrees within 30 minutes, and drops below 3 degrees after 2 hours. After stopping the irradiation for 72 hours, the contact angle returned to about 80.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com