Extracting process of actinidia proteinase

A technology of kiwifruit protease and extraction method, which is applied to the preparation methods of peptides, chemical instruments and methods, hydrolytic enzymes, etc., can solve the problems of no product sales, no public reports, etc., to fill market gaps and low equipment costs. , the effect of quick profit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

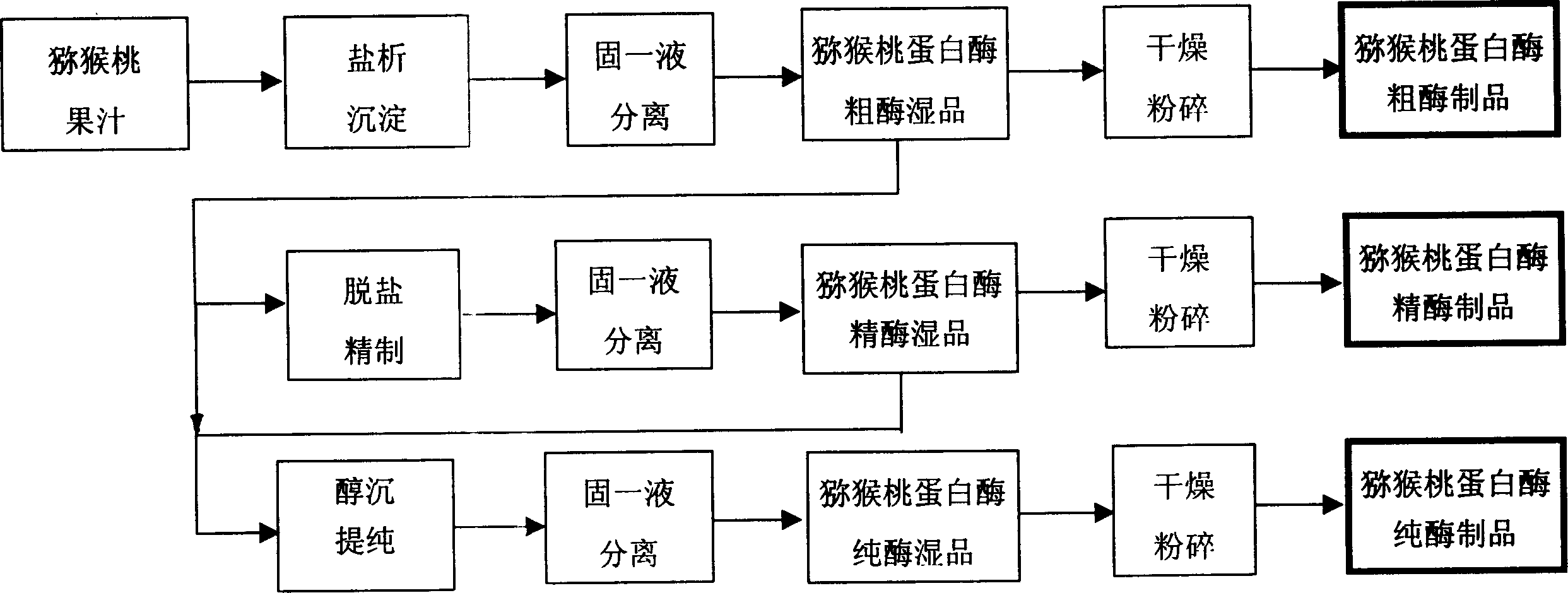

Method used

Image

Examples

example 1

[0041] Example 1 Take 1 liter of kiwi fruit juice, add 1 liter of the prepared 25% sodium chloride aqueous solution, stir to mix well; adjust the pH to 4.0 with sodium hydroxide solution, and let it stand for 12 hours at 4°C (usually the same day). Juice in the afternoon, then let sit in the fridge overnight). After salting-out precipitation, the juice mixture is clearly separated into upper and lower layers, and the lower layer is the green enzyme paste sediment. The supernatant liquid of the upper layer was sucked out with a siphon; about 800 ml of the sediment in the lower layer was collected, transferred to a Buchner funnel and filtered under reduced pressure to obtain 53.6 g of wet crude enzyme product.

[0042] After 23.6 g of the wet enzyme is naturally spread out, vacuum drying is performed, and the drying temperature is not higher than 40° C., and finally the water content of the crude enzyme is below 5%. The dried crude enzyme was ground with a mortar and passed thr...

example 2

[0045] Example 2 Take 6 liters of kiwi fruit juice, add 4.3 liters of 28% saturated brine, and stir to fully mix the brine and juice. Adjust the pH to 4.3 with sodium hydroxide solution, transfer the mixture to a cold storage at 0°C, and let it settle for 14 hours until the supernatant is clear and transparent; remove the supernatant, and put the lower green enzyme paste into a 220-mesh filter. In the cloth bag, the brine is squeezed out to complete the solid-liquid separation.

[0046] Mix the above wet enzyme with 6 liters of purified water, adjust the pH value to 7.0, stir until completely dissolved, then adjust the pH to 4.6, and let stand for more than 3 hours in a 0°C cold storage; transfer to a centrifuge at 4000r / min speed Perform centrifugation. The precipitates were collected, 5 liters of 80% ethanol solution was added, and after thorough stirring, normal pressure filtration was performed, and then vacuum freeze-dried. Then, it is ground with a ball mill and passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com