Method for synthesizing nusaturated hydrophilic methyl or ethyl end capping polyether

A synthetic method and hydrophilic technology, which is applied in the field of synthesis of unsaturated hydrophilic methyl or ethyl-terminated polyether, and can solve the problems of many by-products, deep color of the product, and low capping rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

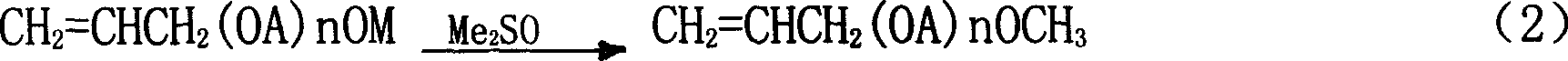

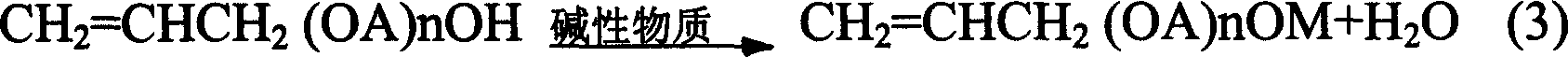

Method used

Image

Examples

Embodiment 1

[0031] Firstly, alkaline sustained-release microcapsules were prepared. Under the protection of nitrogen, add 300 grams of sodium hydroxide particles (particle size is 100-200 μm) in a small glass fluidized bed with an inner diameter of 20 cm and a height of 80 cm. The nitrogen gas velocity was increased to suspend the alkali particles. Then spray into alkaline earth metal salt calcium chloride aqueous solution, the weight ratio of calcium chloride to sodium hydroxide is 0.3:1. When drying, the nitrogen temperature is 125°C. After drying for 2-3 hours, cool to room temperature and store in airtight condition until use.

[0032] Add allyl alcohol polyoxyethylene ether (average degree of addition is 8) 100g, sodium hydroxide microcapsule 35g in the 500ml round bottom flask that is equipped with electronic constant speed stirrer, reflux condenser, thermometer and dropping funnel, Stirring was started, and the temperature was kept at 30-35°C. At the same time, 33.5 g of dimethyl...

Embodiment 2-6

[0034] Use potassium hydroxide, sodium hydroxide or their mixture with sodium carbonate, potassium carbonate instead

[0035] Example

[0036] (The capping rate is determined by quantitative 13 CNMR analysis value is calculated as a benchmark)

Embodiment 7-12

[0038] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com