Nano lightweight composite wall plates made from stalk

A composite wallboard and nano-straw technology, applied in building materials and other directions, can solve the problems of high water absorption, harmful gas, unstable wallboard performance, damage to the human body, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

19

19

[0047] The above-mentioned Nano Jieqibao and Nano Activated Calcium Carbonate can be selected from the Najie brand products developed by the Institute of Light Chemical Industry, Chinese Academy of Sciences, or other similar products.

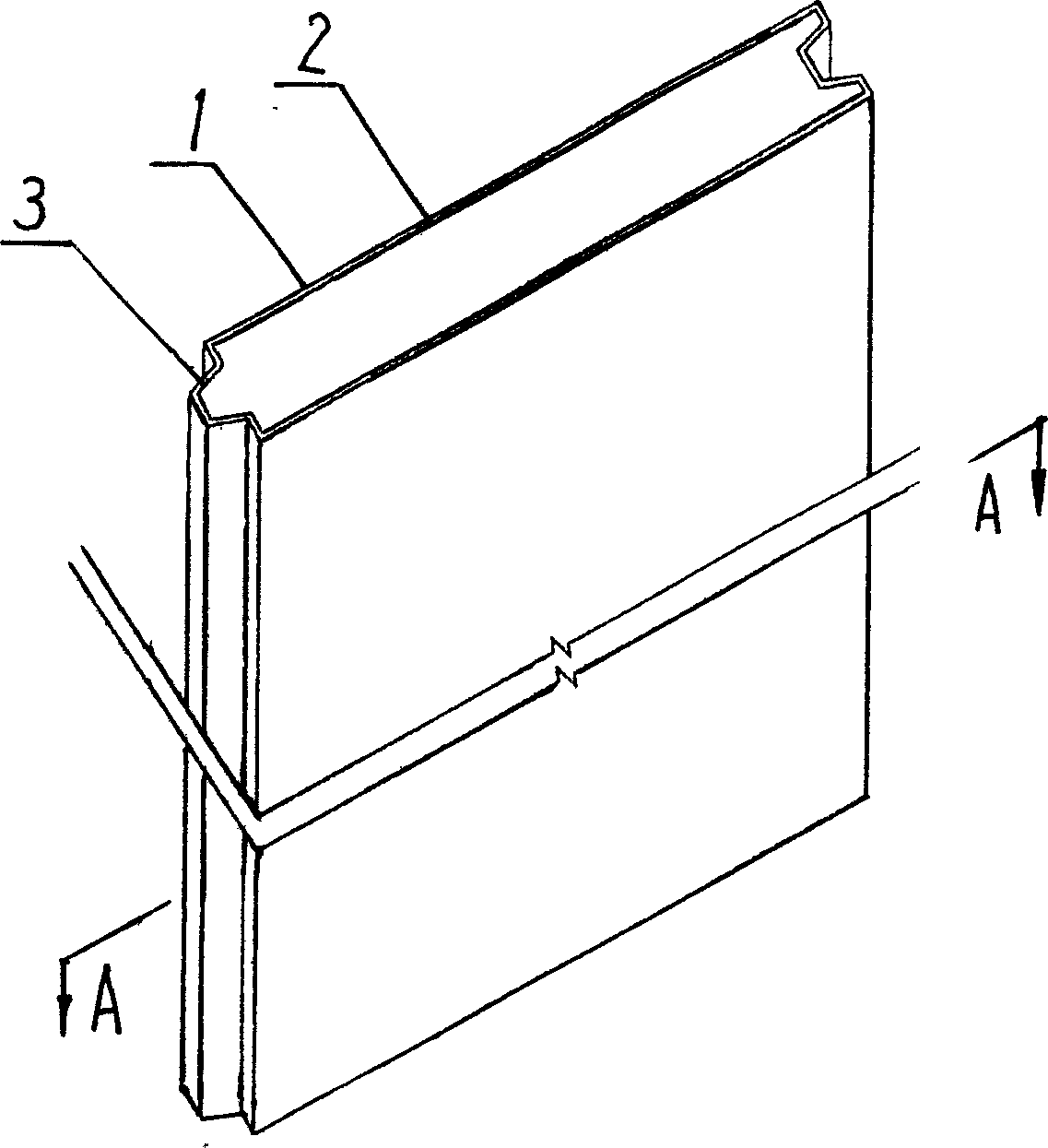

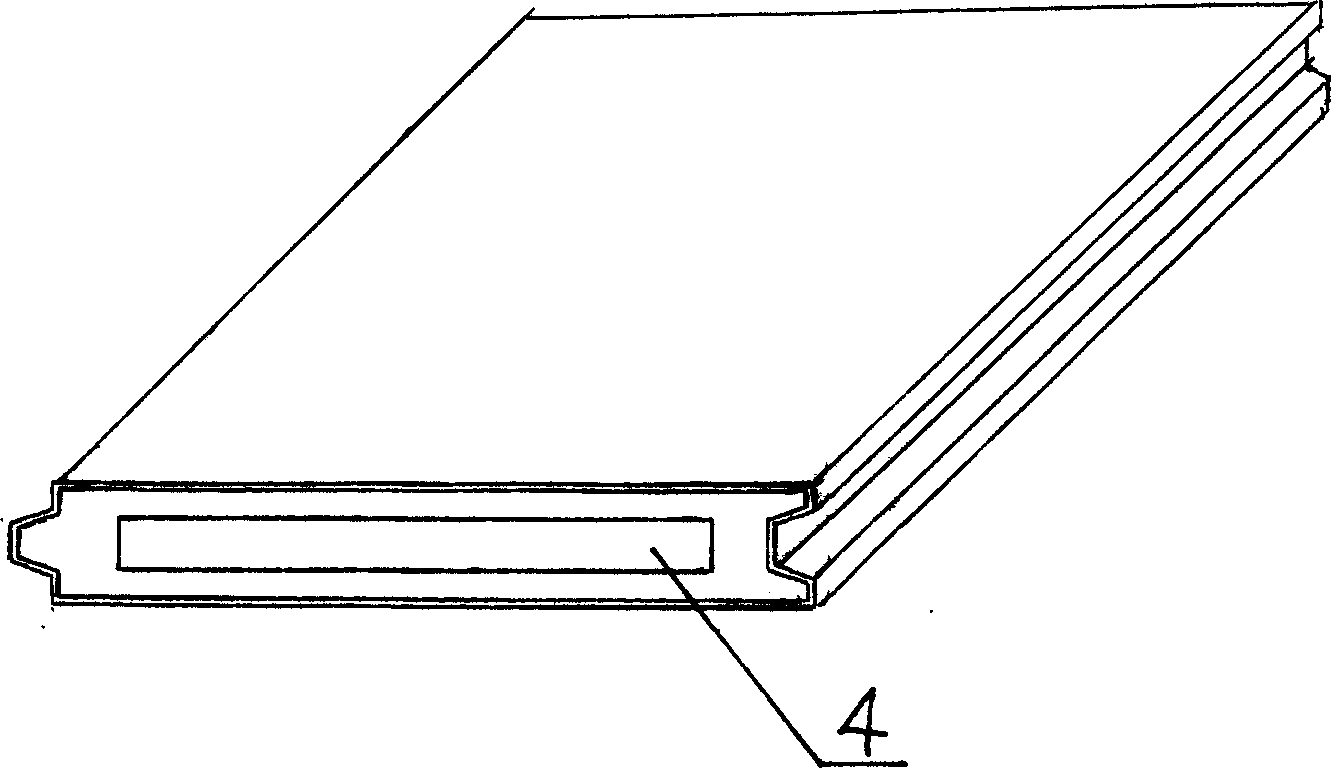

[0048] The structure and shape of the wall panel can be designed according to the needs, see the example figure 1 , 2 , the wallboard surface layer 1 is wrapped with glass fiber cloth 2 around, and a cavity 4 can be left in the wallboard, and a polystyrene foam core board with a thickness of 5 cm is sandwiched in the cavity. For the convenience of connection, the two sides of the wallboard Side is provided with concavo-convex groove 3, and the cavity wall thickness of wallboard can be 2-4 centimetre, and the length of wallboard is 200-350 centimetre, and width is 50-90 centimetre, and specific size is decided according to engineering needs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com