50-litres hydrogen composite cylinder having carbon fiber wholly-wound, reinforced aluminum lining

A technology of winding reinforcement and carbon fiber, which is applied in the field of hydrogen supply equipment, can solve the problems of low safety performance, low weight-to-volume ratio, difficult 35MPa high-pressure hydrogen storage composite gas cylinder composite structure layering sequence, etc., and achieve the best safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

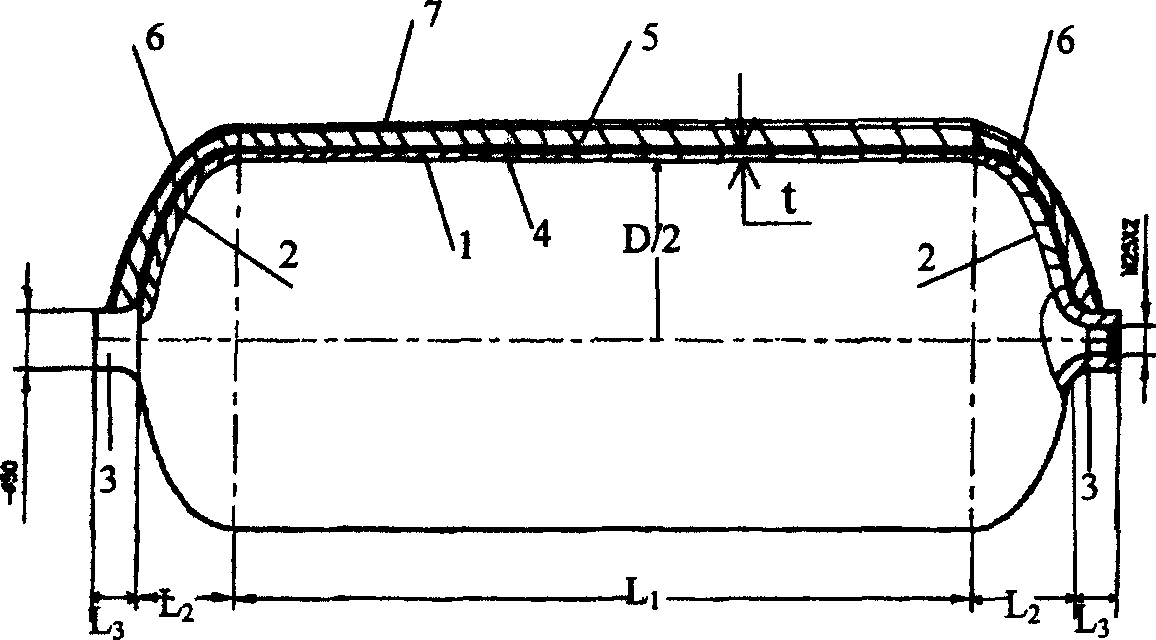

[0021] 1) figure 1 In , the structural dimensions of the aluminum lining shown are respectively taken as:

[0022] The length of cylinder 1 is L 1 =531mm, inner diameter D=327mm, height L of sag at end 2 of the elliptical surface 2 =90mm, including the length L of the bottle mouth 3 with M25 internal thread 3 =50mm, wall thickness t=3.4mm, guarantee that the volume of composite gas cylinder of the present invention is 50 liters.

[0023] 2) Apply a thin layer of polyurethane varnish on the outer surface of the aluminum lining as an anti-electrocorrosion coating 4.

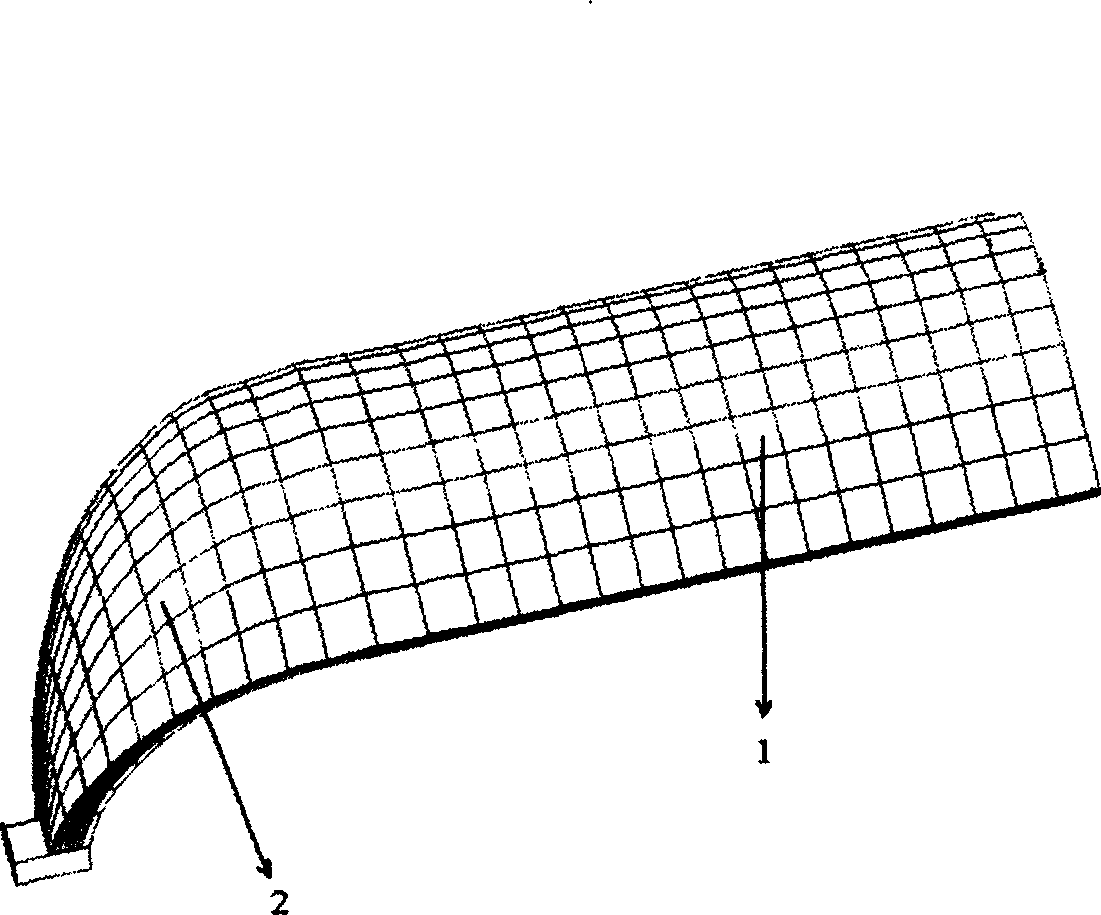

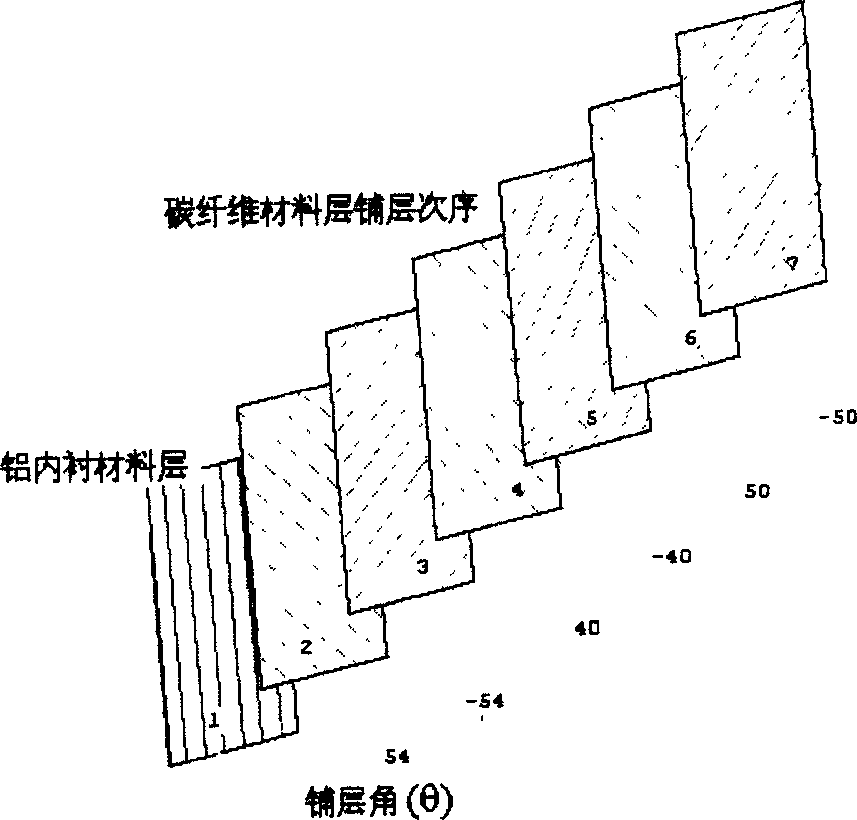

[0024] 3) After the T700-12KC carbon fiber bundle is immersed in epoxy resin, according to a certain design tension T, it is wound on the aluminum lining according to the optimally designed layering sequence; the layering sequence of the carbon fiber winding layer 5 of the aluminum lining cylinder part is:

[0025] [±α 1 / H 3 / ±α 2 / H 2 / ±α 3 / H 2 ],

[0026] The layering sequence of the longitudinal hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com