Method for preparing linalyl acetate by linalool and acetic anhydride

A technology of linalyl acetate and acetic anhydride, which is applied in the field of preparing linalyl acetate from linalool and acetic anhydride, which can solve the difficult separation and recovery of products, increase the production cost of linalyl acetate, low yield of linalyl acetate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

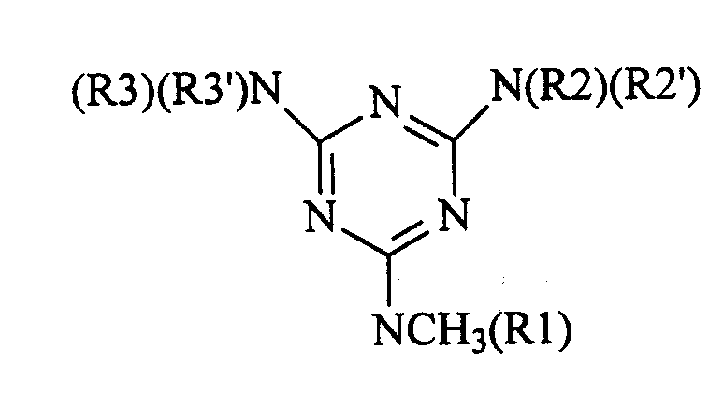

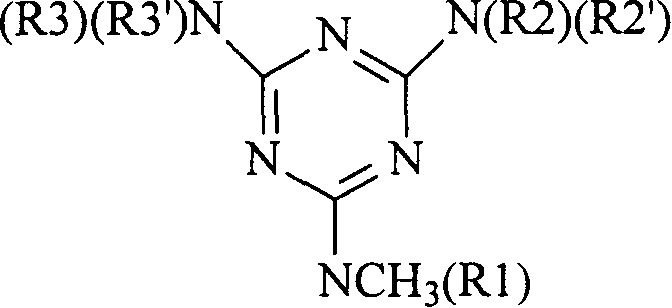

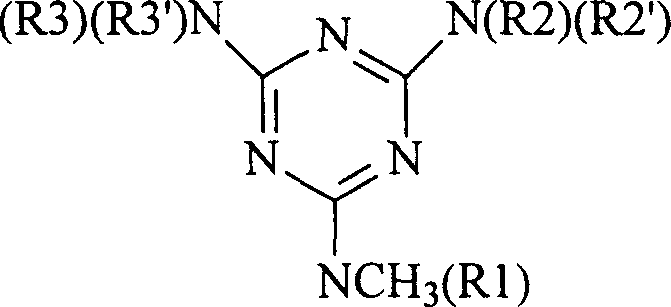

[0017] Catalyst preparation:

[0018] In a 250ml three-necked flask placed on an oil bath, add 0.6g melamine and 18g methyl p-toluenesulfonate, 0.2g NaOH as a catalyst and 10ml toluene as a solvent, stir and raise the temperature to 80°C and maintain it for 6 hours. Then perform hot filtration, wash the filter cake with acetone after cooling, and dry under vacuum at room temperature to obtain the finished catalyst.

[0019] The intensity of characteristic resonant peak of the methyl group was measured by infrared spectroscopy on the catalyst, and the degree of methylation of the methyl-modified melamine was estimated to be 45%.

[0020] Preparation of linalyl acetate:

[0021] Put 33.5g of linalool and 30g of acetic anhydride into a 250ml three-necked flask, add 0.02g of the catalyst obtained above, stir and heat up to 80°C, keep it standing for cooling after 6 hours, remove the catalyst by filtration, and obtain the composition of each component through gas chromatography an...

Embodiment 2~4

[0023] During the preparation of the catalyst, the methylation reaction time of melamine and methyl p-toluenesulfonate was changed to 5, 5.5, and 6.5 hours, respectively, and the methylation degree was 35%, 41%, and 55% respectively. Melamine is as catalyzer, and all the other are with embodiment 1.

Embodiment 5~7

[0025] The preparation of catalyst is with embodiment 1, changes the consumption of catalyst during esterification, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com