Artificial endovascular stent and preparation method thereof

A technology of artificial blood vessels and inner stents, which is applied in the field of medical devices to achieve the effects of increasing flexibility, no heat generation, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

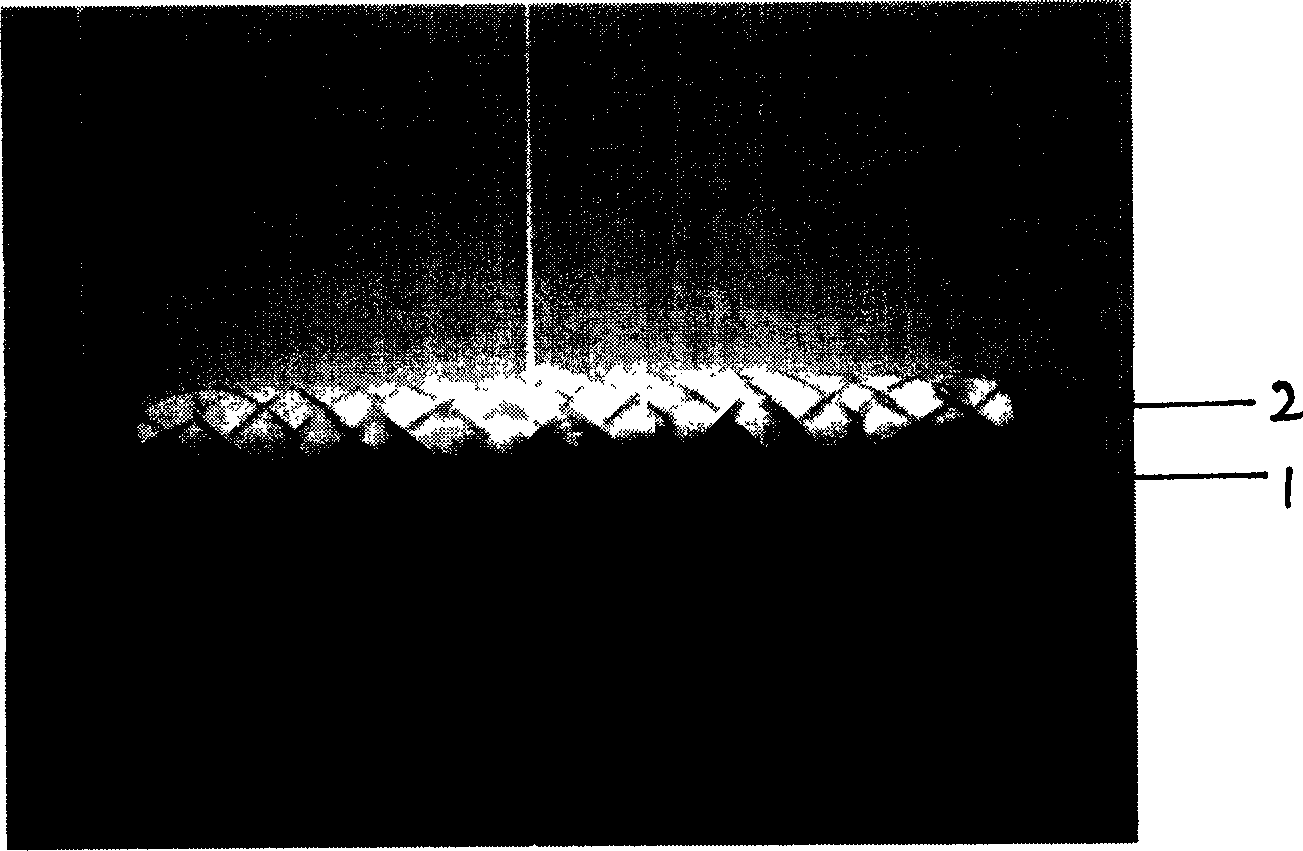

[0030] 1. Preparation of Nitinol Stents

[0031] According to conventional methods, sponge nickel (Ni) and titanium (Ti) are pressed into electrodes, smelted in a consumable furnace, and the smelted consumable ingot is induction remelted to obtain a nickel-titanium alloy ingot, wherein the Ni content is 51.8%, The Ti content is 47.5%. The nickel-titanium alloy ingot was hot-rolled, hot-swaged and cold-drawn to produce a nickel-titanium alloy wire with a diameter of 0.4 mm.

[0032] Use the above-mentioned nickel-titanium alloy monofilament to weave a rough diamond-shaped mesh stent according to the sinusoidal method, and then go through the procedures of setting, welding, heat treatment (three times in total, 400-500 ° C, blued), pickling, cleaning, drying and inspection Made into a finished product. The nickel-titanium alloy stent has a length of 6 cm and a diameter of 11 mm, braided in a rhombus shape, with 7 rhombus peaks on each circumference, and each rhombus has a leng...

Embodiment 2

[0038] 1. Fabrication of Nitinol stents

[0039] According to conventional methods, sponge nickel (Ni) and titanium (Ti) are pressed into electrodes, smelted in a consumable furnace, and the smelted consumable ingot is induction remelted to obtain a nickel-titanium alloy ingot, wherein the Ni content is 52.8%. , Ti content is 46.5%. The nickel-titanium alloy ingot is hot-rolled, hot-swaged and cold-drawn to produce a nickel-titanium alloy wire with a diameter of 0.35 mm.

[0040] Use the above 0.35mm nickel-titanium alloy wire monofilament to weave into a rhomboid mesh stent with a certain diameter and length according to the sinusoidal method. Washing, cleaning, drying and inspection processes make finished products. The obtained nickel-titanium alloy stent has a length of 4 cm and a diameter of 8 mm, and is braided in a rhombus shape. There are 6 rhombus peaks on each circumference, and the length of each rhombus is 1 cm.

[0041] 2. Fabrication of expanded polytetrafluoroe...

Embodiment 3

[0046] 1. Fabrication of Nitinol stents

[0047] According to conventional methods, sponge nickel (Ni) and titanium (Ti) are pressed into electrodes, smelted in a consumable furnace, and the smelted consumable ingot is induction remelted to obtain a nickel-titanium alloy ingot, wherein the Ni content is 55.8%, The Ti content is 43.5%. The nickel-titanium alloy ingot is hot-rolled, hot-swaged and cold-drawn to produce a nickel-titanium alloy wire with a diameter of 0.45 mm.

[0048] Use the above-mentioned nickel-titanium alloy monofilament to weave into a rough mesh stent with a certain diameter and length in the form of a rhombus according to the sinusoidal curve method, and then go through setting, welding, heat treatment (three times in total, 400-500 ° C, blued), pickling, cleaning , drying and inspection processes to make finished products. The obtained nickel-titanium alloy stent has a length of 10 cm and a diameter of 15 mm, and is braided in a rhombus shape, with 8 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com