Lanthanum or yttrium doped aluminum zinc oxide powder and codeposition-supercritical fluid drying method for preparing the same

A zinc-aluminum oxide and supercritical fluid technology, applied in the field of materials, can solve the problems of serious powder agglomeration, good nano-powder materials, and inability to obtain dispersibility, and achieves elimination of powder agglomeration, simple process, and easy product particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Objective: To prepare lanthanum-doped ZAO nanopowder

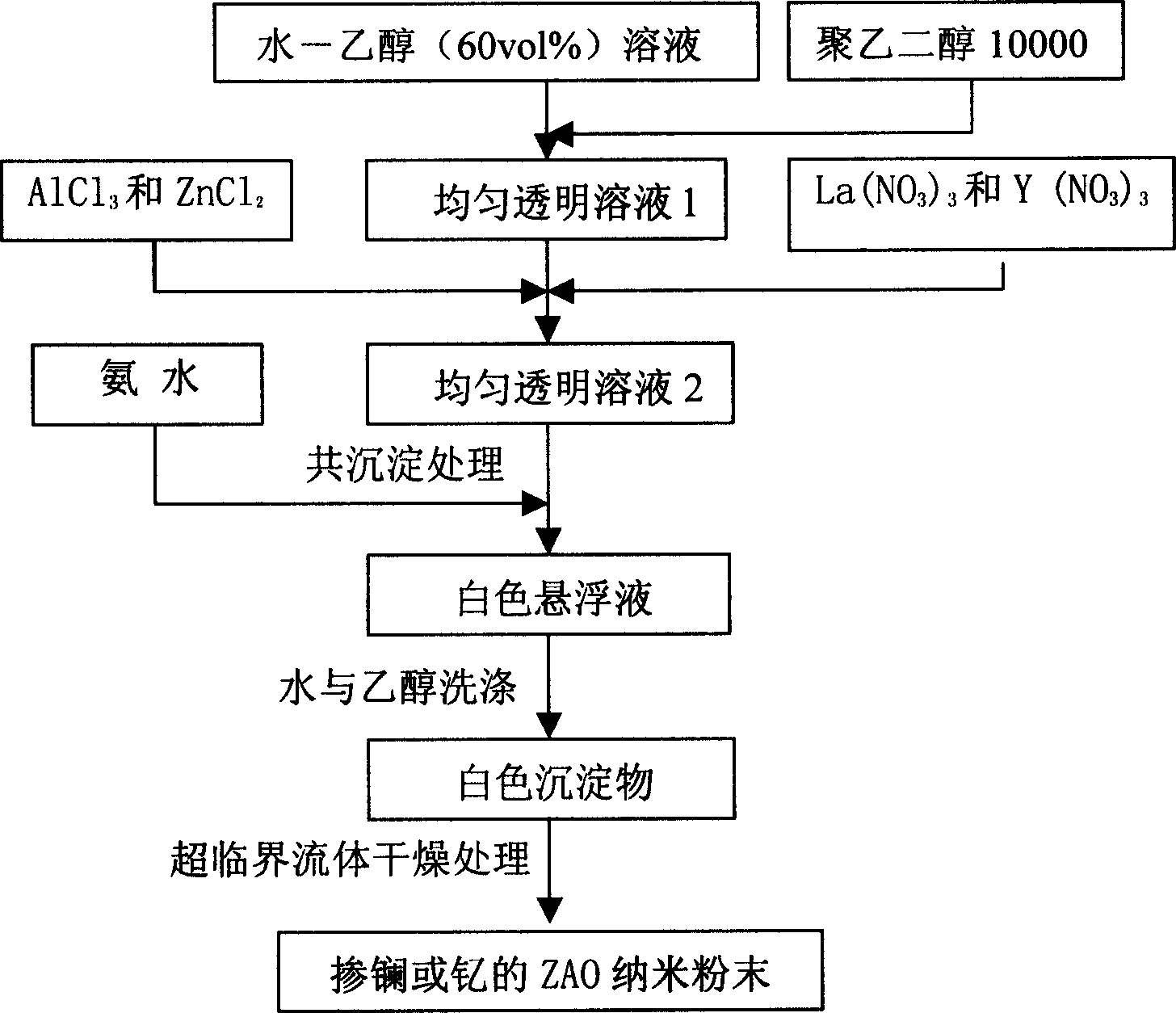

[0026] Method: co-precipitation - supercritical fluid drying preparation technology

[0027] Process: 1 Prepare ethanol-water (60vol%) mixed solution.

[0028] 2. Weigh PEG (polyethylene glycol 10000, the addition amount is 2.4-3.0% of the mass of ZAO powder), add to the above ethanol-water solution and stir to obtain colorless and transparent solution 1.

[0029] 3 Weigh crystalline zinc chloride (ZnCl 2 ) and aluminum chloride (AlCl 3 ), dissolved in the solution, and prepared into a solution 2 with a zinc chloride concentration of 1mol / L, AlCl 3 The amount of addition is based on ZnO: Al 2 o 3 =97:3 (mass ratio) weighing. Weigh the La that accounts for the total amount of 4.5wtZAO 2 o 3 Dissolved in nitric acid solution, the prepared La(NO 3 ) 3 The solution was redissolved in solution 2.

[0030] 4. During the process of stirring the above-mentioned solution 2, continuously add ammonia water with a co...

Embodiment 2

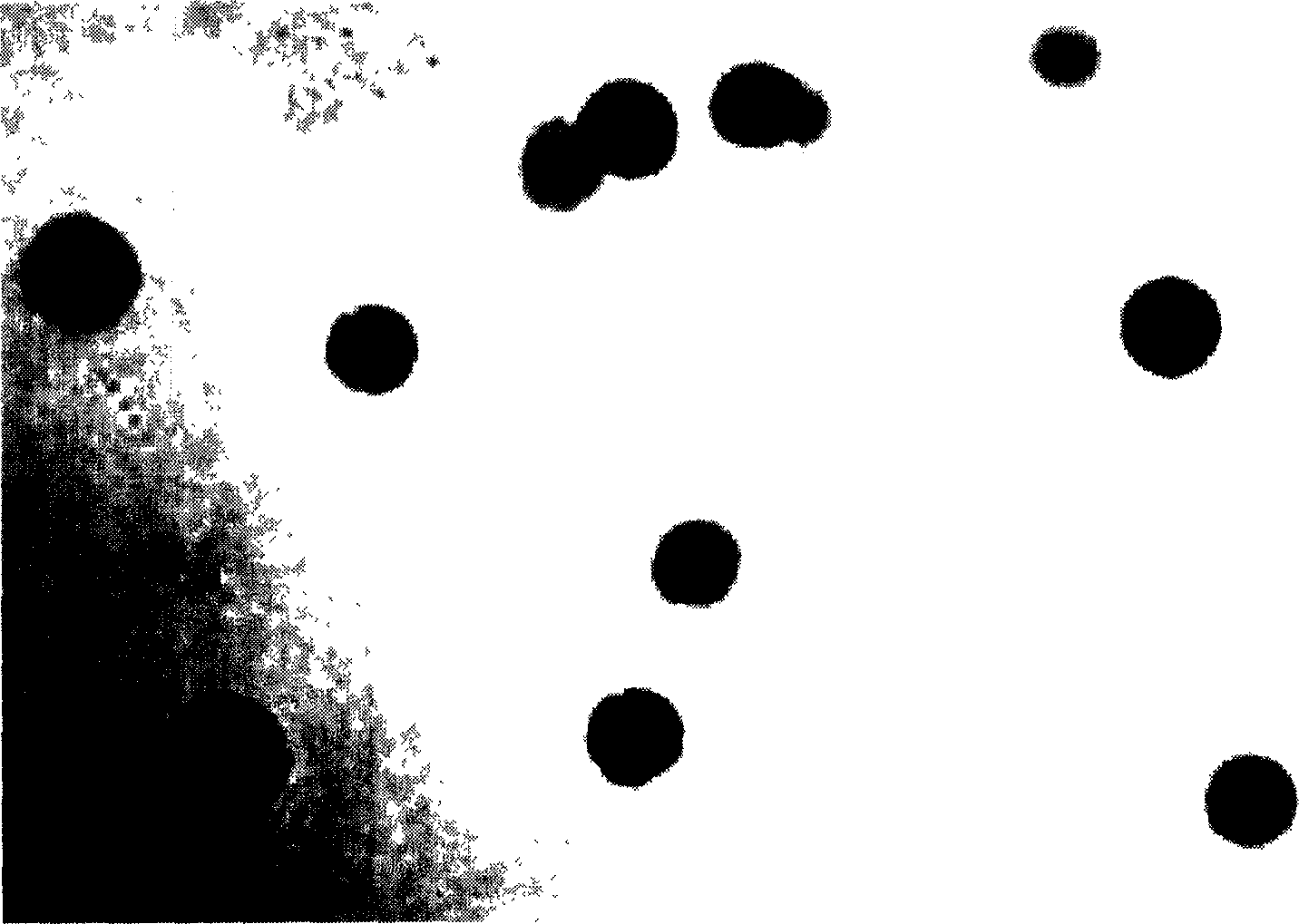

[0035] The method of use is the same as in Example 1, and the supercritical fluid drying link is introduced in the drying process of the powder. After the precipitate synthesized by co-precipitation is washed with deionized water and ethanol, the ethanol solvent has no obvious liquid-gas interface under critical conditions. Non-shrinkage liquid phase drying is carried out to eliminate or reduce the degree of agglomeration between zinc-aluminum composite oxide nanopowders. The critical condition of ethanol solvent is temperature: 533K, atmospheric pressure: 7.5Mpa, and the prepared zinc-aluminum composite oxide nanopowder doped with rare earth element lanthanum or yttrium has an average particle size of about 60nm, particle shape close to spherical, and dense fine grain Organization, better dispersion and smaller particle size distribution, uniform particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com