Double-fuel homogeneous compression ignition/quasi-homogeneous compression compound combustion system

A homogeneous compression ignition and combustion system technology, applied in fuel injection control, machine/engine, engine control, etc., can solve the problems of improper combustion organization soot, large air-fuel ratio, high fuel consumption rate, etc., and achieve extended operating conditions range, reduction of harmful emissions, and the effect of saving oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

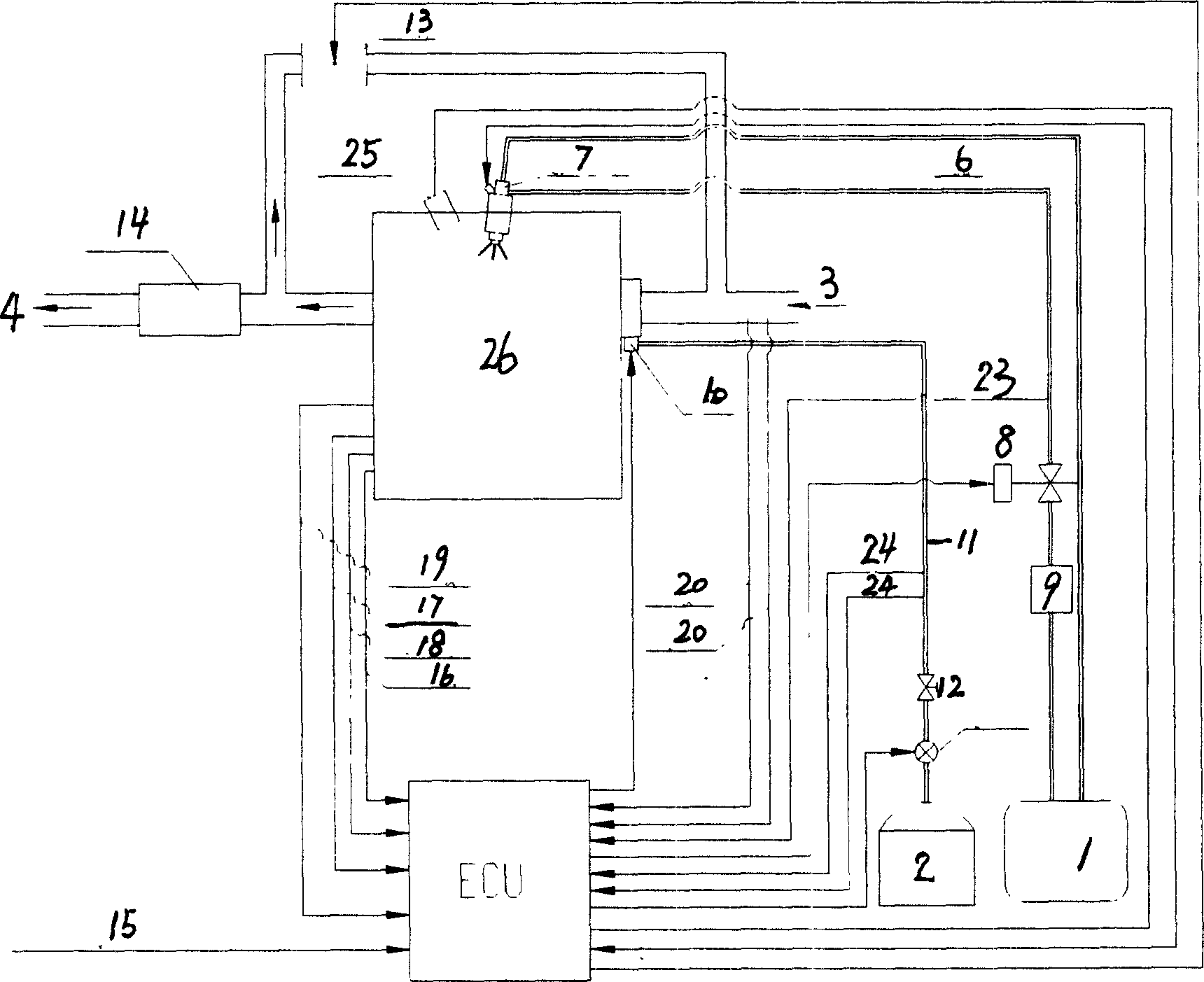

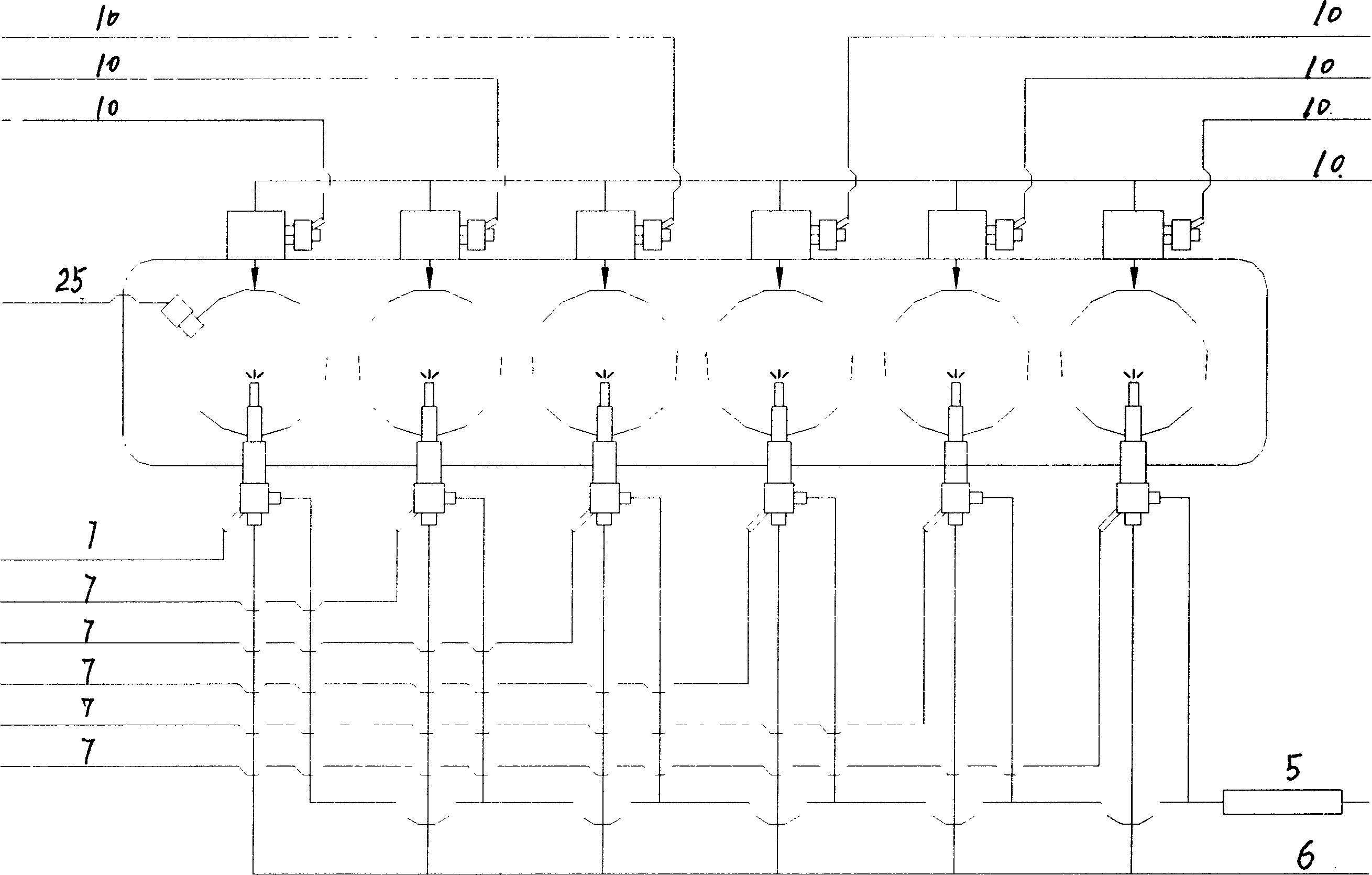

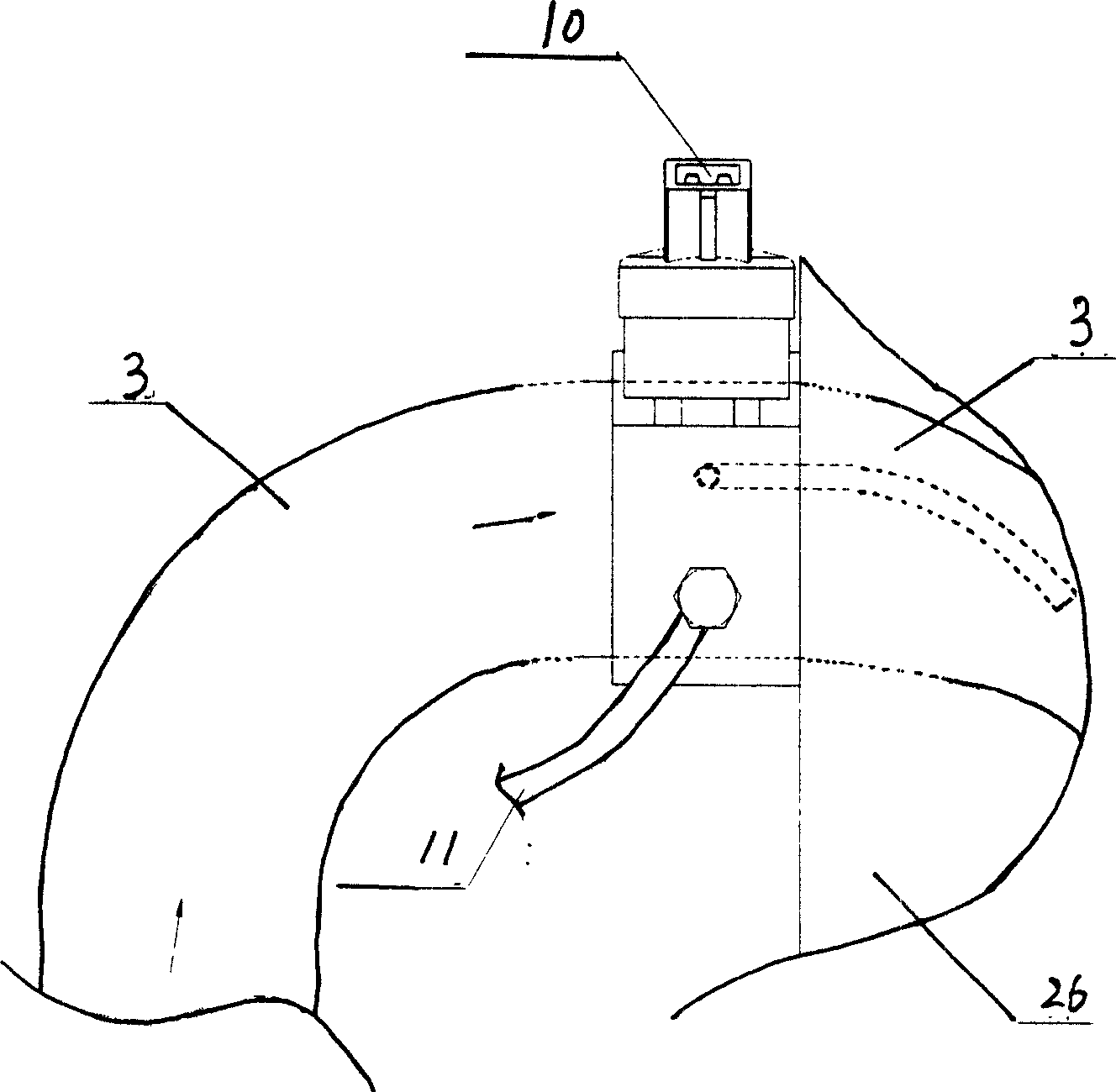

[0018] Taking a six-cylinder engine as an example, such as figure 1 , 2 , Shown in 3 and 4: a diesel and natural gas dual-fuel HCCI / QHCCI composite combustion system, characterized in that it consists of a diesel tank 1, a natural gas tank 2, a high-pressure common rail injection device, an airway injection device, and a cooling exhaust gas recirculation device Composed of an electronic control unit; the diesel tank is connected to the engine through a high-pressure common rail injection device, the gas tank is connected to the engine through an airway injection device, and the cooling exhaust gas recirculation device is connected to the intake pipe 3 and exhaust pipe 4 of the engine 26 respectively; The input terminal of the control unit receives the engine operating condition parameter signal output by the engine, including the accelerator position signal 15, the speed signal 16, the crank angle signal 17, the top dead center signal 18, the cooling water temperature signal 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com