Nanometer silica gel composite board and producing method thereof

A production method and technology for composite panels, which are applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of global ecological environment damage, non-waterproof wood, complicated processes, etc., to protect the ecological and natural environment. , The effect of preventing trees from being felled and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 as figure 1 Shown:

[0040] a. Select 18 kg of nano fly ash with a particle size of 30-35nm, 30 kg of micron fly ash of 100-400 mesh, 15 kg of micron calcium oxide of 100-400 mesh, 15 kg of Portland cement, 1 kg of calcium sulfate, 4 kg of polyacrylate, 5 kg of red pine or white pine wood powder or 2-3 cm long polypropylene fiber;

[0041] b. add the water of 30% of the total weight of materials used in the above steps, i.e. 26.4 kg of water and stir until evenly stirred;

[0042] c. Put the uniformly stirred slurry into the mold or roll it into a plate-shaped blank;

[0043] d. The blank is dried, cured and shaped to form the substrate 1 .

Embodiment 2

[0044] Example 2 as figure 1 Shown:

[0045] a. Select 25 kg of nano fly ash with a particle size of 30-35nm, 20 kg of micron fly ash of 100-400 mesh, 25 kg of micron calcium oxide of 100-400 mesh, 10 kg of Portland cement, 2 kg of calcium sulfate, 6 kg of polyacrylate, 3 kg of red pine or white pine wood powder or 2-3 cm long polypropylene fiber;

[0046] b. Use maleic anhydride and water at a ratio of 1:100 to stir and hydrolyze at high speed to form a coupling agent. Put red pine or white pine wood powder or 2 ~ 3cm long polypropylene fiber into 1 kg of coupling agent, mix well, realize the modification of reinforcing material with coupling agent, to strengthen red pine or white pine wood powder or 2 ~ 3cm Combination of 3cm long polypropylene fibers with other materials such as fly ash;

[0047] c. Add 40% water of the materials used in the above steps, that is, 36.8 kg of water and stir until evenly stirred;

[0048] c. Put the uniformly stirred slurry into the mold o...

Embodiment 3

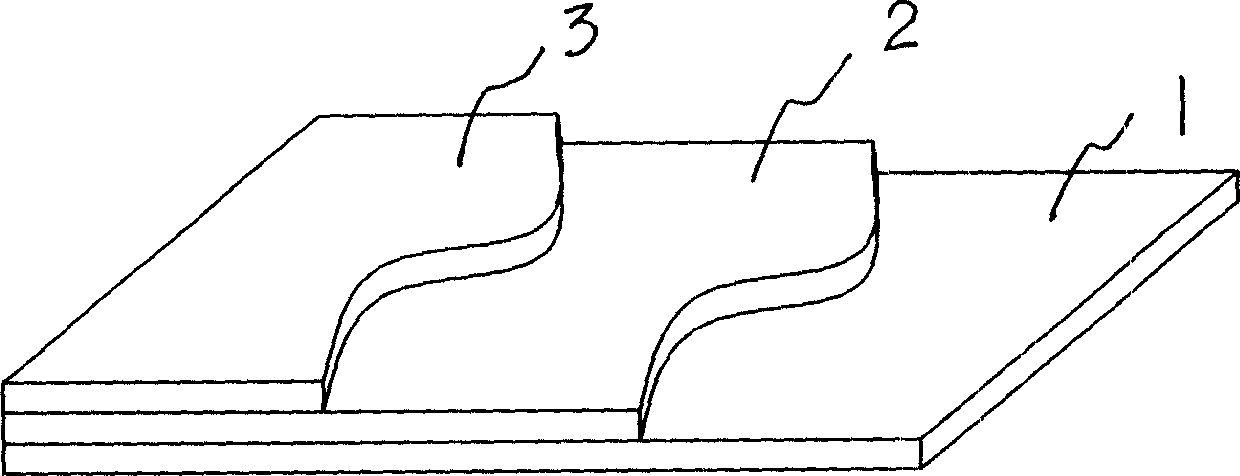

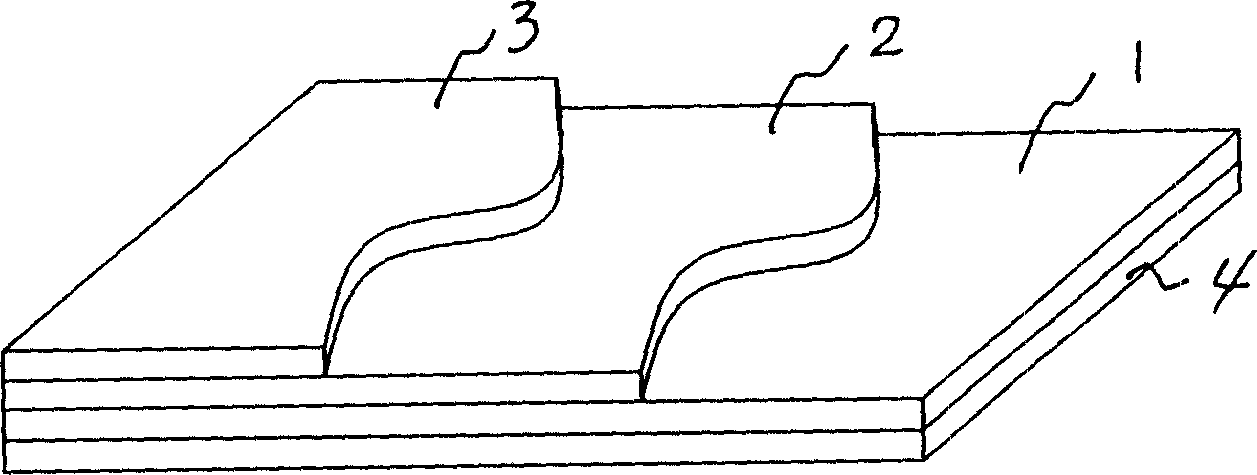

[0050] Example 3 as figure 2 Shown:

[0051] a. form the substrate 1 in the manner of embodiment 1 or 2;

[0052] b. Flatten the surface of the substrate, paste decorative cloth or decorative paper or decorative board, etc., to form a decorative layer 2 on the substrate 1;

[0053] c. Mix polyester (No. 191 unsaturated polyester), curing agent (cyclohexanone peroxide) and accelerator (cobalt naphthenate) in a weight ratio of 100:2~5:0.5~3.5 at room temperature , the polyester and curing agent must be fully mixed before adding the accelerator.

[0054] d. Spray or brush the material formed in step c on the decorative layer 2, and at the same time cover the undried flame-retardant and wear-resistant layer 3 with a plastic film until it is dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com