Preparing method for aldehyde acid tanning agent

A technology of aldehyde acid tanning agent and glyoxylic acid, which can be used in small hide/big hide/leather/fur treatment, tanning treatment, small hide/big hide/leather skin/fur chemical treatment, etc. It can solve the problem of promoting chromium absorption The effect is small and other problems, to improve the absorption rate and fixation rate, reduce the effect of chromium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

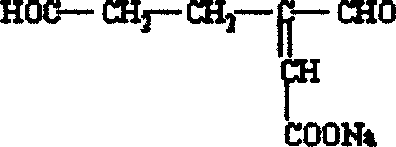

[0006] Example 1: First mix 1 mole of glutaraldehyde with 1 mole of glyoxylic acid aqueous solution, and then add sodium hydroxide catalyst under the protection of nitrogen to make the pH of the system 7.5, heat to 85°C, and keep for 0.5-1.5 hours for reaction. Distill under reduced pressure at 45-65°C or use benzene as a water-carrying agent to reflux for about 1 hour to remove the water produced by the reaction, cool to room temperature, adjust the pH value to 5.5-6.5 with acid, and add water to adjust the solid content of the system to 40%. The structural formula of the condensation product is:

[0007]

Embodiment 2

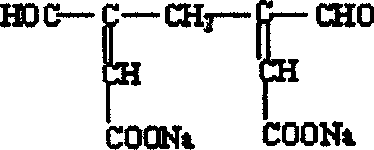

[0008] Example 2: First mix 1 mole of glutaraldehyde with 2 moles of glyoxylic acid aqueous solution, and then add sodium hydroxide catalyst under the protection of nitrogen to make the pH of the system 8.5, heat to 45°C, and keep for 0.5-1.5 hours for reaction. Distill under reduced pressure at 45-65°C or use benzene as a water-carrying agent to reflux for about 1 hour to remove the water produced by the reaction, cool to room temperature, adjust the pH value to 5.5-6.5 with acid, and add water to adjust the solid content of the system to 40%. The structural formula of the condensation product is:

[0009]

Embodiment 3

[0010] Example 3: First mix 1 mole of glutaraldehyde and 0.5 mole of sodium glyoxylate in an aqueous solution, and then add sodium hydroxide catalyst under the protection of nitrogen to make the pH of the system 8, heat to 55°C, and react at a temperature of 0.5-1.5 Distill under reduced pressure at 45-65℃ or reflux under reduced pressure with benzene as a water-carrying agent for about 1 hour to remove the water produced by the reaction, cool to room temperature, adjust the pH value to 5.5-6.5 with acid, and add water to adjust the solid content of the system to 40 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com