Production method of freeze dried chickenpox attenuated live vaccine and products therefrom

A live attenuated vaccine and production method technology, applied in the field of live attenuated varicella vaccine and products, can solve the problems of restricting the large-scale production of varicella vaccine, reducing the ability of VZV, and low VZV production, and achieve the removal or reduction of bovine serum residues Quantity, improve stability, reduce the effect of adverse reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

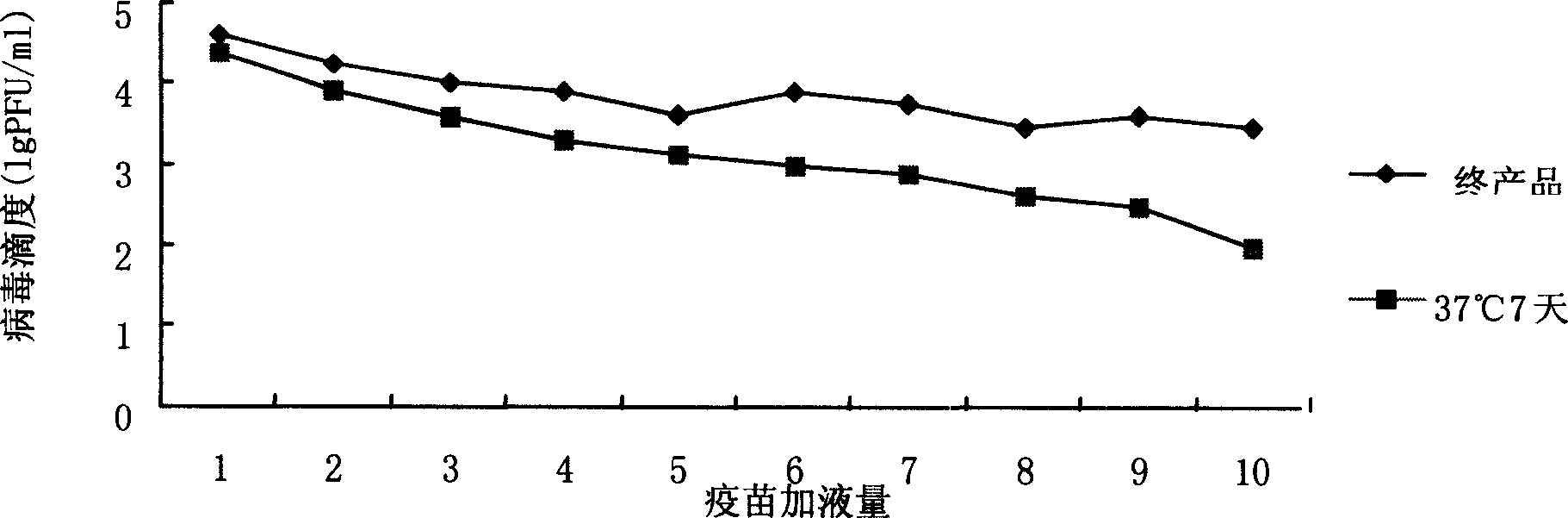

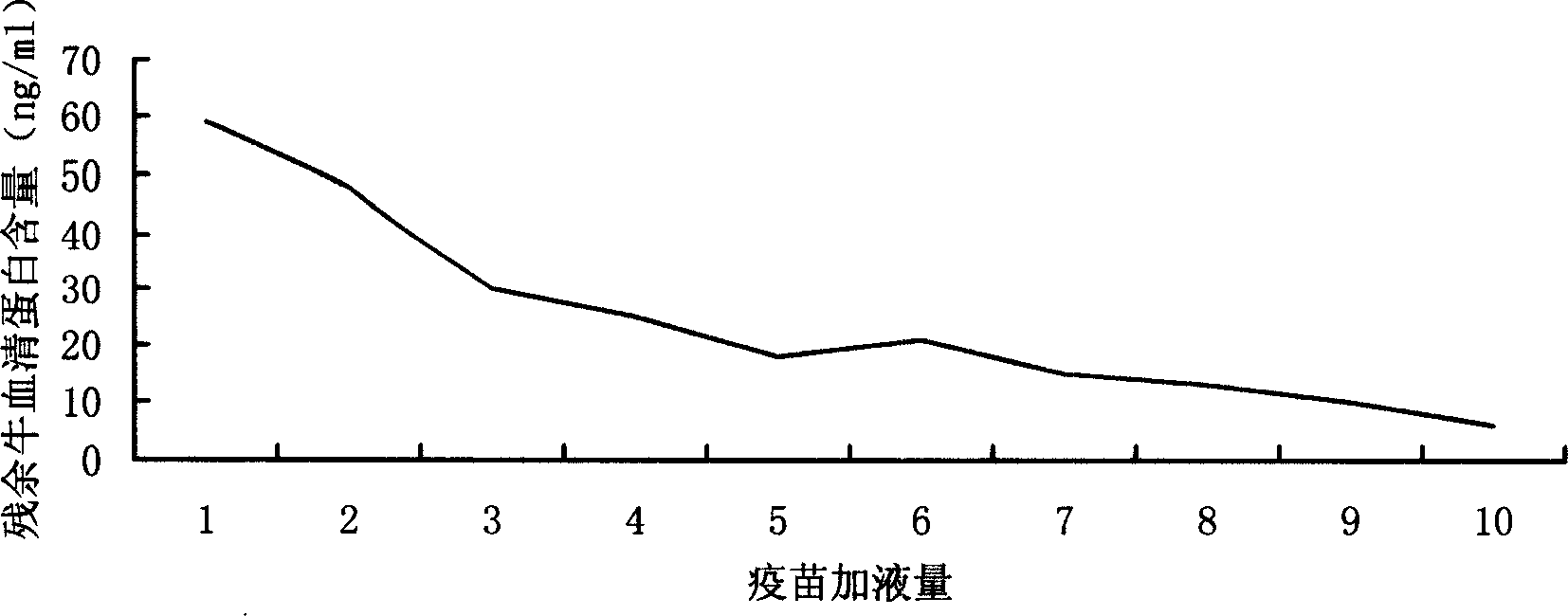

[0053] Take human embryonic lung diploid cell 2BS (32 generations) monolayer and subculture according to 1:4, adjust the rotating speed of the bottle machine to 30 rpm, culture at 37°C for 5 days, grow into a dense monolayer, and place in the culture bottle Add the virus seeds in the ratio of virus seeds to cells 1:60, infect the cells, and incubate at 35°C for 3 days until the cytopathic changes reach more than 75%, use Earle's solution three times the original maintenance solution volume Rinse the cell surface, wash away the bovine serum, and add the vaccine solution containing the vaccine stabilizer to harvest. The mass ratio of each component in the vaccine liquid is: 2.5% of sucrose, 2% of gelatin, 0.5% of sodium glutamate, 0.1% of urea, 0.1% of arginine, 0.3% of sorbitol and 1% of human serum albumin. Freeze and thaw the harvested vaccine solution at -70°C, break the cells by ultrasonic at 20KHz, centrifuge at 1000rpm at 4°C for 30 minutes to remove cell debris, clarify ...

Embodiment 2

[0055] Firstly, human embryonic lung diploid cells 2BS (passage 31) were subcultured at a ratio of 1:2. The medium used for cell expansion is MEM supplemented with 10% calf serum, pH 7.2. Place the cell culture flask at 37°C. Culture under rotation for 3 days (20 rpm / hour) to form a uniform and dense monolayer of cells, and then discard the growth solution. Virus seeds were added to the culture flask at a ratio of 1:80 virus seeds to cells for infection, and cultured in rotation at 35° C. (rotating speed 20 rpm) for 4 days. When more than 75% of the typical lesions appear on the 2BS cells, pour out the original maintenance solution, wash the cell surface with Earle's solution four times the original maintenance solution volume, wash away the bovine serum, and add the vaccine solution containing the vaccine stabilizer to harvest. The mass ratio of each component in the vaccine liquid is: 2.5% of sucrose, 2% of gelatin, 0.5% of sodium glutamate, 0.1% of urea, 0.1% of arginine,...

Embodiment 3

[0057] Firstly, human embryonic lung diploid cells 2BS (passage 38) were subcultured at a ratio of 1:2. The medium used for cell expansion is MEM supplemented with 12% calf serum, pH 7.2. Place the cell culture bottle at 37° C. for 4 days under rotation (25 rpm / hour) to form a uniform and dense monolayer of cells, and then discard the growth medium. Virus seeds were added to the culture flask at a ratio of 1:90 virus seeds to cells for infection, and rotated at 35° C. (15 revolutions / hour) for 4 days. When more than 75% of the typical lesions appear on the 2BS cells, pour out the original maintenance solution, wash the cell surface with Earle's solution three times the original maintenance solution volume, wash away the bovine serum, and add the vaccine solution containing the vaccine stabilizer to harvest. The mass ratio of each component in the vaccine liquid is: 1.5% of sucrose, 4% of gelatin, 0.5% of sodium glutamate, 0.2% of urea, 0.1% of arginine, 0.4% of sorbitol and 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com