White light fluorescence powder excitated by blue light and its application mfg. technology and mfg. apparatus

A technology of blue light excitation and manufacturing process, applied in the field of phosphors, can solve the problems of difficult cubic garnet structure, unsuitable for large-scale production, difficult to achieve particle size, etc., and achieves low cost of manufacturing equipment, good fluidity, and narrow particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

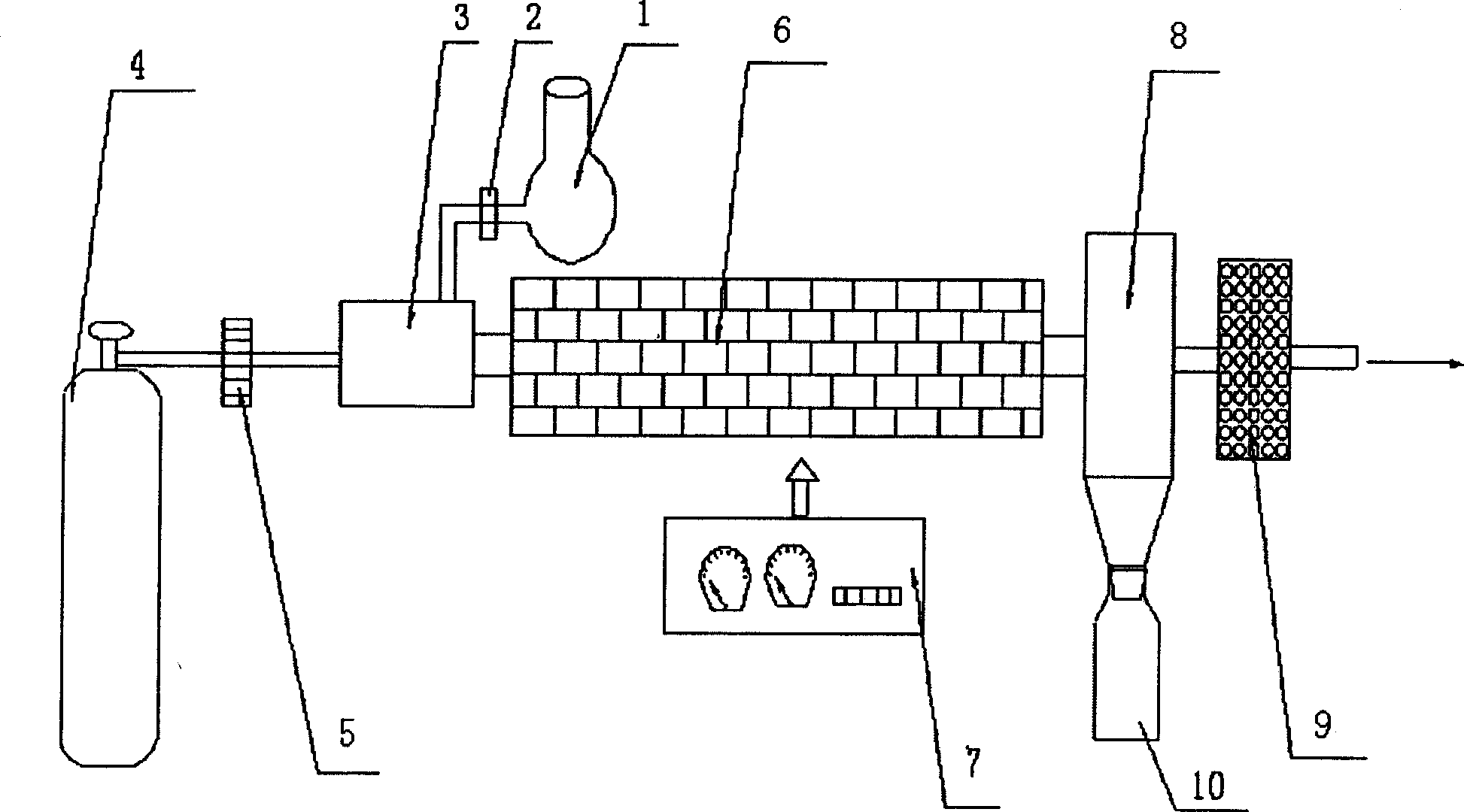

[0039] weigh Y 2 o 3 28.2404g, Gd 2 o 3 8. Dissolve 1947g in an appropriate amount of nitric acid to form a clear aqueous solution of rare earth nitrate, then add Al(NO 3 ) 3 9H 2 O 189.4611g, H 2 SiO 3 3.9050g, Ce(NO 3 ) 3 ·6H 2 O2.5502g, add deionized water to dilute 2000ml, this mixed solution is the precursor solution to be atomized, and add the solution to the automatic liquid addition device 1. The temperature of the multi-temperature zone tubular reactor 6 is raised to 1300° C., and the temperature is controlled by the temperature control system 7 . The tubular reaction furnace includes a quartz reaction tube, a cylindrical furnace, a resistance heating wire wrapped around the outer wall of the furnace, and light refractory bricks and insulation cotton on the outside. The tubular reactor is controlled by multiple temperature zones, including 4 independent heating Each temperature zone is equipped with a temperature measuring point, the reaction furnace is ...

Embodiment 2

[0045] weigh Y 2 o 3 231.3673g, Gd 2 o 3 163.8944g was dissolved in an appropriate amount of nitric acid to form a clear rare earth nitrate aqueous solution, and then Al(NO 3 ) 3 9H 2 O 1894.6110g, H 2 SiO 3 39.0500g, Ce(NO 3 ) 3 ·6H 2 O25.5020g, add deionized water to dilute 5000ml, this mixed solution is the precursor solution to be atomized, and add the solution to the automatic liquid adding device 1. The temperature of the multi-temperature zone tubular reactor 6 is raised to 800° C., and the temperature is controlled by the temperature control system 7 . The tubular reaction furnace includes a quartz reaction tube, a cylindrical furnace, a resistance heating wire wrapped around the outer wall of the furnace, and light refractory bricks and insulation cotton on the outside. The tubular reactor is controlled by multiple temperature zones, including 10 independent heating Each temperature zone is equipped with a temperature measuring point, the angle between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com