Process for clean conversion of tantalum niobium ore

A tantalum-niobium ore and clean technology, which is applied in the clean conversion field of extracting potassium hexatantalate (6O19·nH2O) and potassium metatantalate (O3), can solve the problem of low decomposition rate of tantalum-niobium ore, large consumption of HF acid and environmental pollution. and other problems, to achieve the effect of improving resource utilization, huge environmental benefits, and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

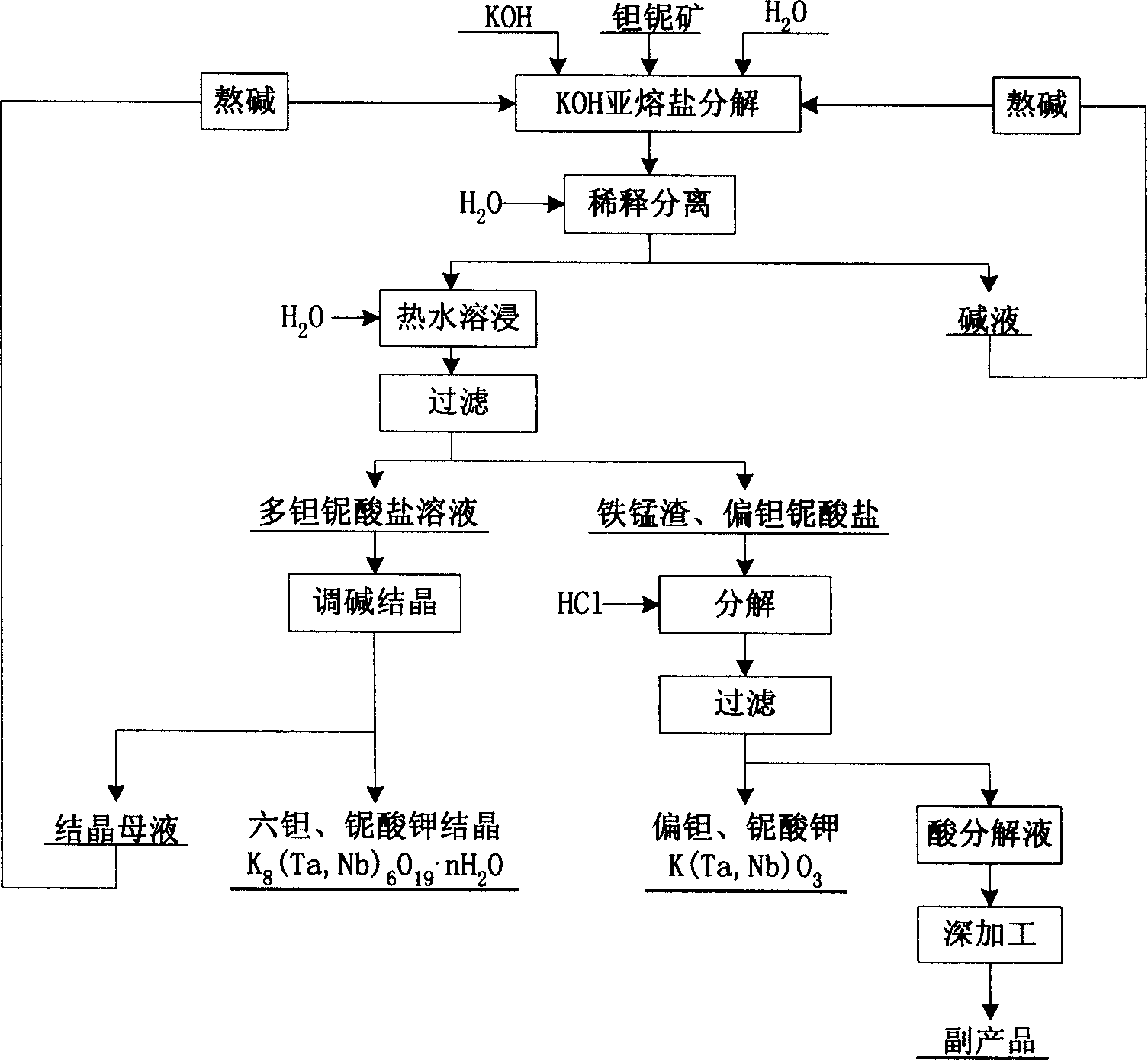

Image

Examples

Embodiment 1

[0025] The potassium hydroxide alkali solution that circulates back to the reaction kettle is heated up to 300 ° C, and -200 mesh tantalum-niobium ore is added. The mass ratio of alkali solution: tantalum-niobium ore is 4: 1, mixed completely under stirring, and reacted for 3 hours to obtain Decomposition products;

[0026] At 30°C, dilute the above decomposition product with water until the KOH concentration in the solution is 600g / L, filter to obtain the crude product containing potassium tantalum (niobium) and a concentrated potassium hydroxide solution containing very little impurity, the potassium hydroxide The concentrated solution can be used for the decomposition reaction in the above steps after evaporation and dehydration;

[0027] At 70°C, the crude product containing potassium tantalum (niobium) was leached for 30 minutes with a potassium hydroxide solution of 88 g / L, and filtered while it was hot to obtain potassium hexatantalum (niobium) (K 8 (Ta, Nb) 6 o 19 ·...

Embodiment 2

[0032] The potassium hydroxide alkali solution that circulates back to the reactor is heated to 340°C, and -200 mesh refractory tantalum and niobium enrichment slag is added. The mass ratio of alkali solution: refractory tantalum and niobium enrichment slag is 3:1, and the Mix completely and react for 1 hour to obtain the decomposition product;

[0033] At 20°C, dilute the above-mentioned decomposition product with water until the KOH concentration in the solution is 550g / L, filter to obtain the crude product containing potassium tantalum (niobium) and a concentrated solution of potassium hydroxide containing very little impurity, the potassium hydroxide The concentrated solution can be used for the decomposition reaction in the above steps after evaporation and dehydration;

[0034] At 60°C, the crude product containing potassium tantalum (niobium) was leached for 40 minutes with a potassium hydroxide solution of 60 g / L, and filtered while it was hot to obtain potassium hexat...

Embodiment 3

[0039] The potassium hydroxide alkali solution that circulates back to the reaction kettle is heated to 280°C, and -200 mesh refractory tantalum and niobium enrichment slag is added. The mass ratio of alkali solution: refractory tantalum and niobium enrichment slag is 7:1, and the Completely mixed and reacted for 8 hours to obtain decomposition products;

[0040] At 110°C, dilute the above decomposition product with water until the KOH concentration in the solution is 750g / L, filter to obtain the crude product containing potassium tantalum (niobate) and a concentrated potassium hydroxide solution containing very little impurity, the potassium hydroxide The concentrated solution can be used for the decomposition reaction in the above steps after evaporation and dehydration;

[0041] At 100°C, the crude product containing potassium tantalum (niobium) was leached for 40 minutes with a potassium hydroxide solution of 200 g / L, and filtered while hot to obtain potassium hexatantalum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com