Explosive

A technology of explosives and emulsified explosives, which is applied in the field of explosives and can solve the problems of explosive condensation and difficulty in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

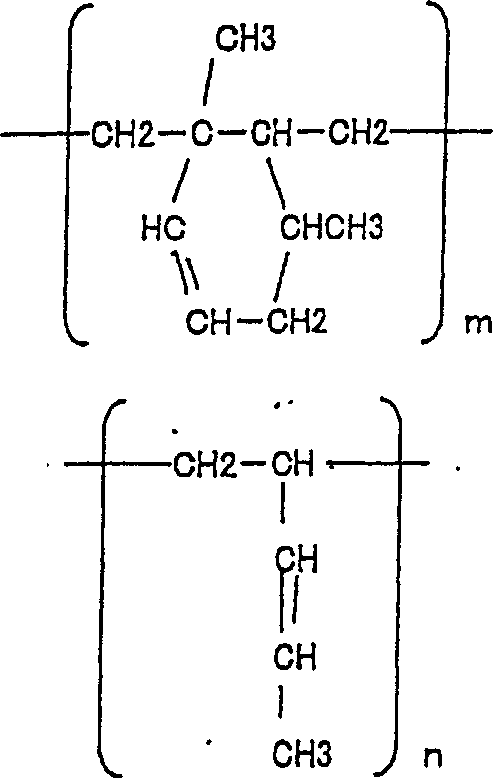

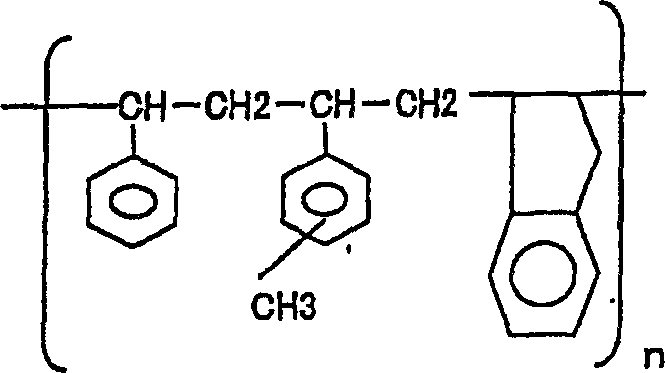

Method used

Image

Examples

Embodiment 1

[0054] Add 90°C oxidant aqueous solution consisting of 75.0 parts of ammonium nitrate, 4.8 parts of sodium nitrate and 10.6 parts of water to 1.5 parts of microcrystalline wax, ethylene vinyl acetate copolymer resin (produced by DU PONT-MITSUI POLYCHEMICALS, trade name: EVAFLEX P-2807 , the number average molecular weight is 20000-30000, the melt flow rate is 15g / 10 minutes) in the mixture of 1.4 parts, sorbitan monooleate 2.9 parts, after fully stirring to obtain a water-in-oil emulsion. 3.8 parts of glass microspheres (specific gravity: 0.25 g / cc) were added thereto as fine hollow spheres, and stirred and mixed to obtain the water-in-oil emulsion explosive of the present invention. This water-in-oil emulsion explosive was molded by an extrusion molding machine having a die having a diameter of 8 mm, and cut into 10 mm lengths with a knife to obtain the explosive of the present invention. The specific gravity of the obtained explosive was 1.17.

Embodiment 2

[0056]Add 75.0 parts of ammonium nitrate, 4.8 parts of sodium nitrate and 10.6 parts of water to 1.5 parts of microcrystalline wax, ethylene vinyl acetate copolymer resin (produced by TOSOHCORPORATION, trade name: ULTRACEN, number average molecular weight: 37000, melt Volume flow rate is 150g / 10 minutes) in the mixture of 1.4 parts, sorbitan monooleate 2.9 parts, through fully stirring to obtain water-in-oil type emulsion. 3.8 parts of glass microspheres (specific gravity: 0.25 g / cc) were added thereto as fine hollow spheres, and stirred and mixed to obtain the water-in-oil type emulsion explosive in the present invention. This water-in-oil emulsion explosive was molded by an extrusion molding machine having a die having a diameter of 8 mm, and cut into 10 mm lengths with a knife to obtain the explosive of the present invention. The specific gravity of the obtained explosive was 1.17.

Embodiment 3

[0069] Add 90°C oxidant aqueous solution consisting of 75.0 parts of ammonium nitrate, 4.8 parts of sodium nitrate, and 10.6 parts of water to 2.0 parts of microcrystalline wax, ethylene vinyl acetate copolymer resin (produced by TOSOHCORPORATION, trade name: ULTRACEN722, melt flow rate: 400g / 10 minutes) in a mixture of 0.9 parts and sorbitan monooleate 2.9 parts, and fully stirred to obtain a water-in-oil emulsion. 3.8 parts of glass microspheres (specific gravity: 0.25 g / cc) were added thereto as fine hollow spheres, and stirred and mixed to obtain the water-in-oil emulsion explosive of the present invention. This water-in-oil emulsion explosive was molded by an extrusion molding machine having an extrusion die having a diameter of 8 mm, and cut into 10 mm lengths with a knife to obtain the explosive of the present invention. The specific gravity of the obtained explosive was 1.17.

[0070] The obtained explosives were subjected to the same detonation velocity, solidificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com