Process for preparing salicin

A preparation process, the technology of salicin, which is applied in the field of preparation process of salicin, can solve the problems of unseen extraction process, etc., and achieve the effects of high yield, good reproducibility, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

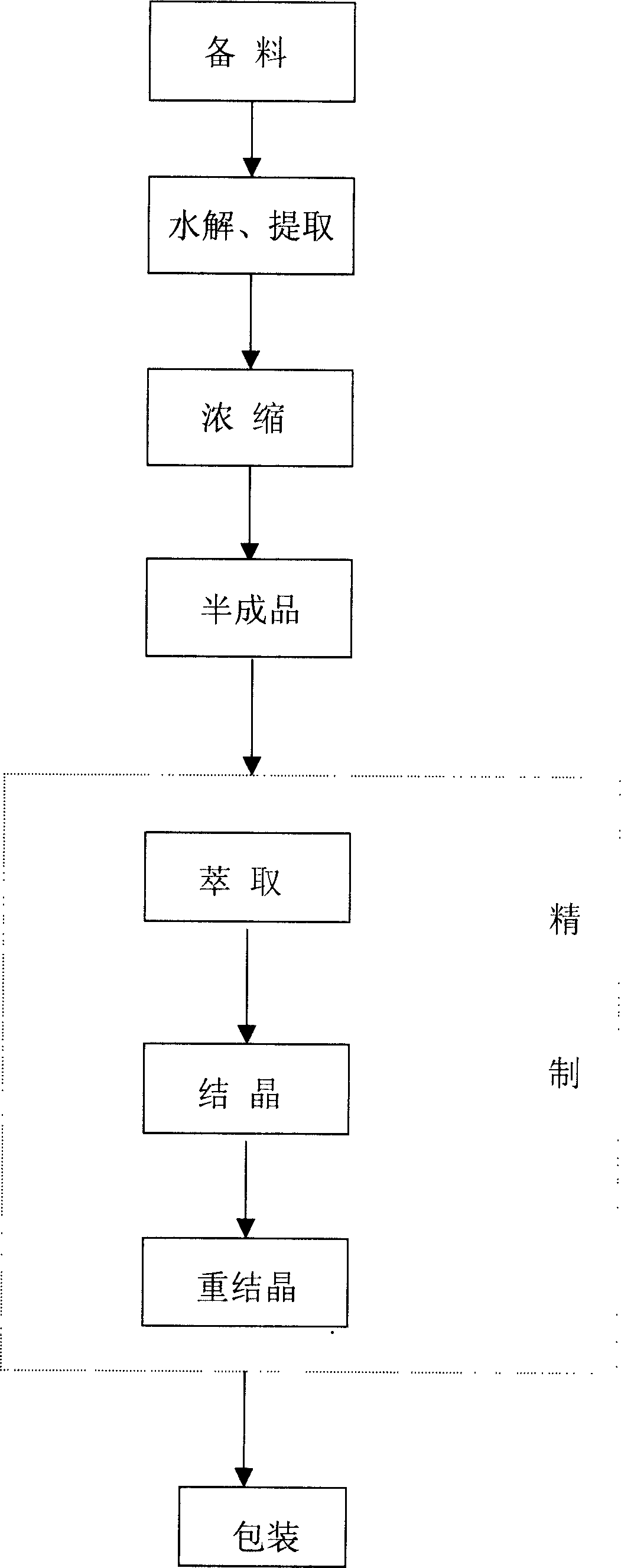

Image

Examples

Embodiment 1

[0022] Embodiment 1, the present invention comprises the following steps successively:

[0023] 1. Crush: Crush 50 kg of white willow branches and leaves into 1-2 cm small pieces of raw material. If the raw material is too large, the extraction will not be thorough, and if the raw material is too small, the residue will be difficult to remove;

[0024] 2. Hydrolysis and extraction: Add 2.5 kg of calcium oxide and 15 kg of water into the raw materials and mix well, put them into the extraction tank, and hydrolyze for 3.5 hours to hydrolyze the salicin derivatives in the raw materials; then add 80% 200 kilograms of ethanol, reflux extraction 80 minutes and filter, residue extracts 2 times again similarly, merges filtrate; Extract is carried out vacuum concentration, temperature is controlled below 80 ℃, concentrates filtrate to obtain extractum (being semi-finished product) 30 kilograms, specific gravity is 1.1;

[0025] 4. Refining steps: (1) Extraction, dissolve the extract wi...

Embodiment 2

[0026] Embodiment 2, the present invention comprises the following steps successively:

[0027] 1. Crush: Crush 50 kg of white willow branches and leaves into small pieces of 1-2 cm;

[0028] 2. Hydrolysis and extraction: add 1.5 kg of sodium hydroxide and 10 kg of water into the raw materials and mix well, put them into the extraction tank, and hydrolyze for 1.5 hours; add 200 kg of 80% ethanol to the extraction tank, reflux extraction for 40 minutes and filter, The residue was also extracted 3 times again, and the filtrate was combined; the extract was concentrated in vacuum, the temperature was controlled below 80°C, and the concentrated filtrate obtained 32 kg of extract, with a specific gravity of 1.2;

[0029] 4. Refining steps: (1) Extraction, dissolve the extract with 15 kg of water, add 20 kg of ethyl acetate for extraction, separate the extract and water phase, then repeatedly add 20 kg of ethyl acetate for extraction in the water phase, Repeat the extraction 2 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com